Stretch-orientated silane cross-linked polyethylene pipe and its preparing process

A technology of cross-linked polyethylene and silane cross-linking, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of environmental stress cracking resistance and other important performance degradation, and achieve environmental stress cracking and stress resistance. Good mouth cracking performance and high pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

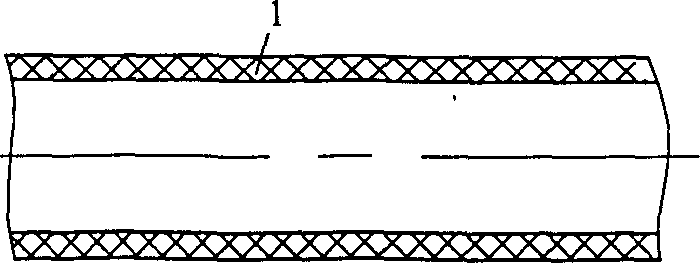

[0038] figure 1 The diagram of Example 1 of the silane crosslinked polyethylene pipe of the present invention is given. The silane crosslinkable polyethylene material in the pipe wall undergoes a radial unidirectional (or radial and axial bidirectional) stretching and orientation process, and then hydrolyzes, condenses and crosslinks to form a silane crosslinked polyethylene structure layer 1 .

Embodiment 2

[0040] Fig. 2 shows the diagram of Embodiment 2 of the silane crosslinked polyethylene pipe of the present invention. The silane-crosslinkable polyethylene material in the pipe wall is processed by radial unidirectional (or radial and axial bidirectional) stretching and orientation process, and then undergoes hydrolysis, condensation and crosslinking reaction to form the inner layer 2 of silane crosslinked polyethylene structure. A layer of thermoplastic is compositely extruded on the outer periphery of the inner layer 2 of the silane cross-linked polyethylene structure to form a pipe hot-melt connection layer 3 (or an adhesive connection layer).

Embodiment 3

[0042] image 3 The diagram of Example 3 of the silane crosslinked polyethylene pipe of the present invention is given. There is an inner layer 4 of silane cross-linked polyethylene structure oriented by radial unidirectional (or radial and axial bidirectional) stretching in the pipe wall. A layer of hot-melt adhesive (or a blend of hot-melt adhesive and polymer) is compounded on the outer periphery of the inner layer 4 of the silane cross-linked polyethylene structure to form a hot-melt connection layer 5 (adhesive connection layer).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com