Soluble material and process for three-dimensional modeling

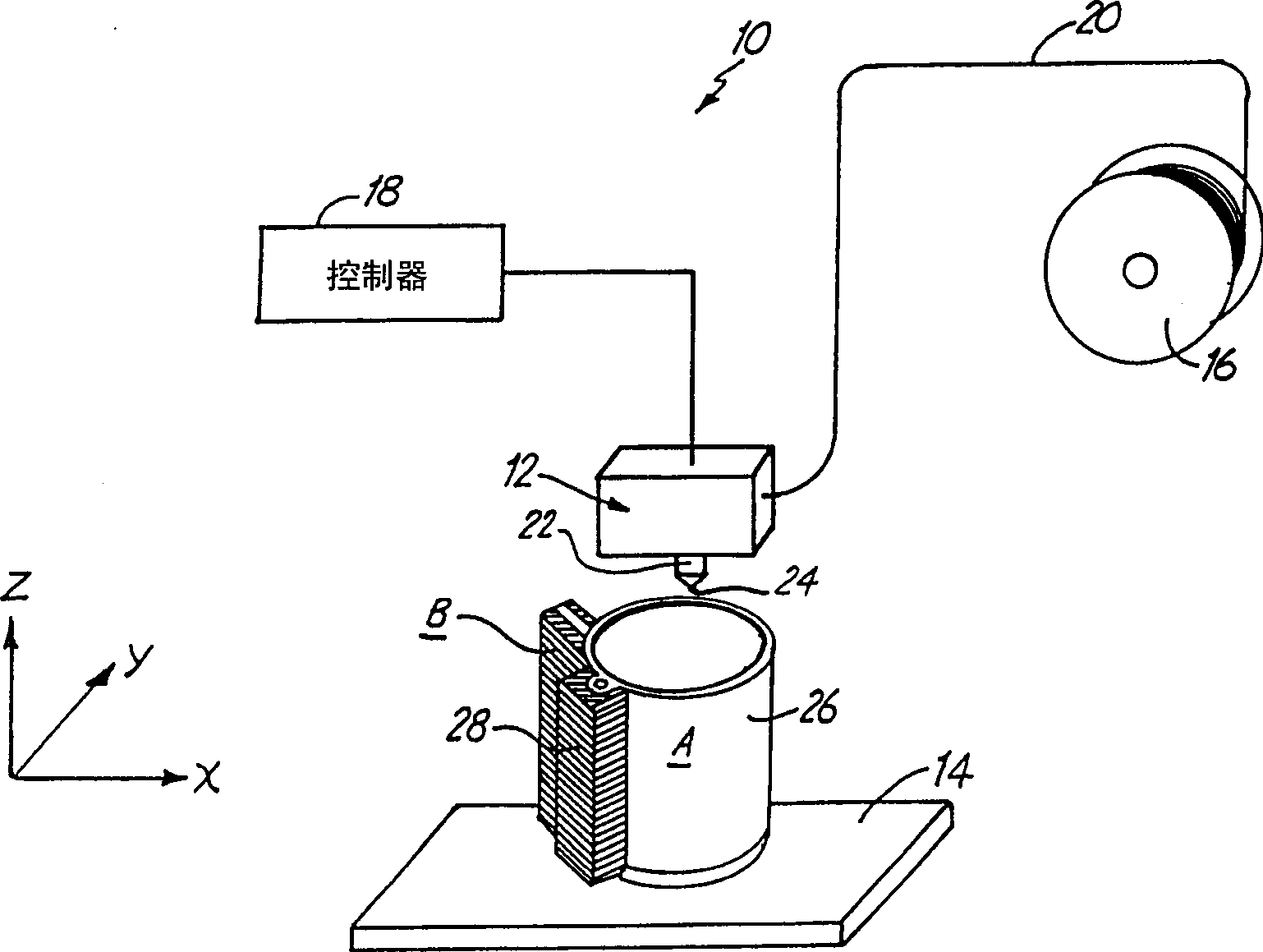

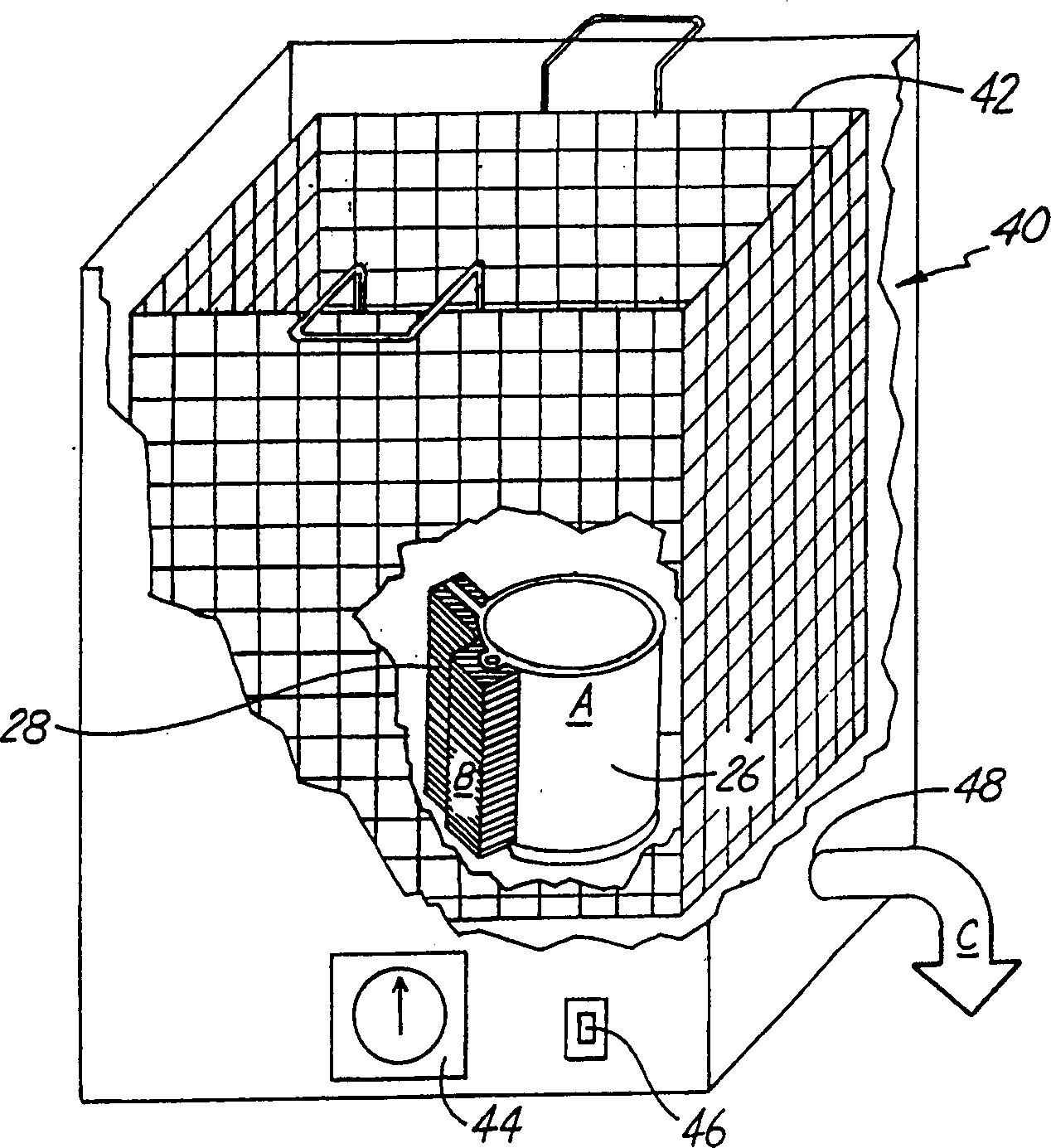

A technology of three-dimensional objects and thermoplastic materials, which is applied in the direction of liquid material additive processing, additive processing, processing and manufacturing, etc., and can solve problems such as model damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0041] The soluble thermoplastic component comprised 74% by weight base polymer and 26% by weight butylphenyl diphenyl phosphate plasticizer. The base polymer consists of copolymers of higher and lower molecular weight methacrylic acid and methyl methacrylate. The base polymer comprised roughly 50% by weight of the higher molecular weight copolymer and 50% by weight of the lower molecular weight copolymer with a tolerance of plus or minus 5% by weight of each. Each copolymer contained methacrylic acid and methyl methacrylate in a weight percent ratio of 1:2. Higher molecular weight copolymers are characterized by high viscosity (low flow) and low molecular weight copolymers are characterized by low viscosity (high flow). The melt flow rate of copolymer is determined by plasticizing every kind of copolymer with the butylphenyl diphenyl phosphate plasticizer of weight 26%, and the melt flow rate of the high molecular copolymer of plasticization is at 0.4~0.8g / The range of 10m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com