Short path aluminium extrusion machine front feeding system and its gripping pliers type adaptive ingot supply device

An aluminum extrusion, short stroke technology, applied in the field of the front loading clamp type adaptive ingot supply device of the short stroke aluminum extrusion press, can solve the problem of increasing the oil volume and liter in the master cylinder, the pressure relief time, and increasing the sealing , wear of guide sleeve and guide plate, long stroke of extrusion rod, etc., to achieve good press performance and process operability, enhance structural strength and overall rigidity, and reduce the impact of oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

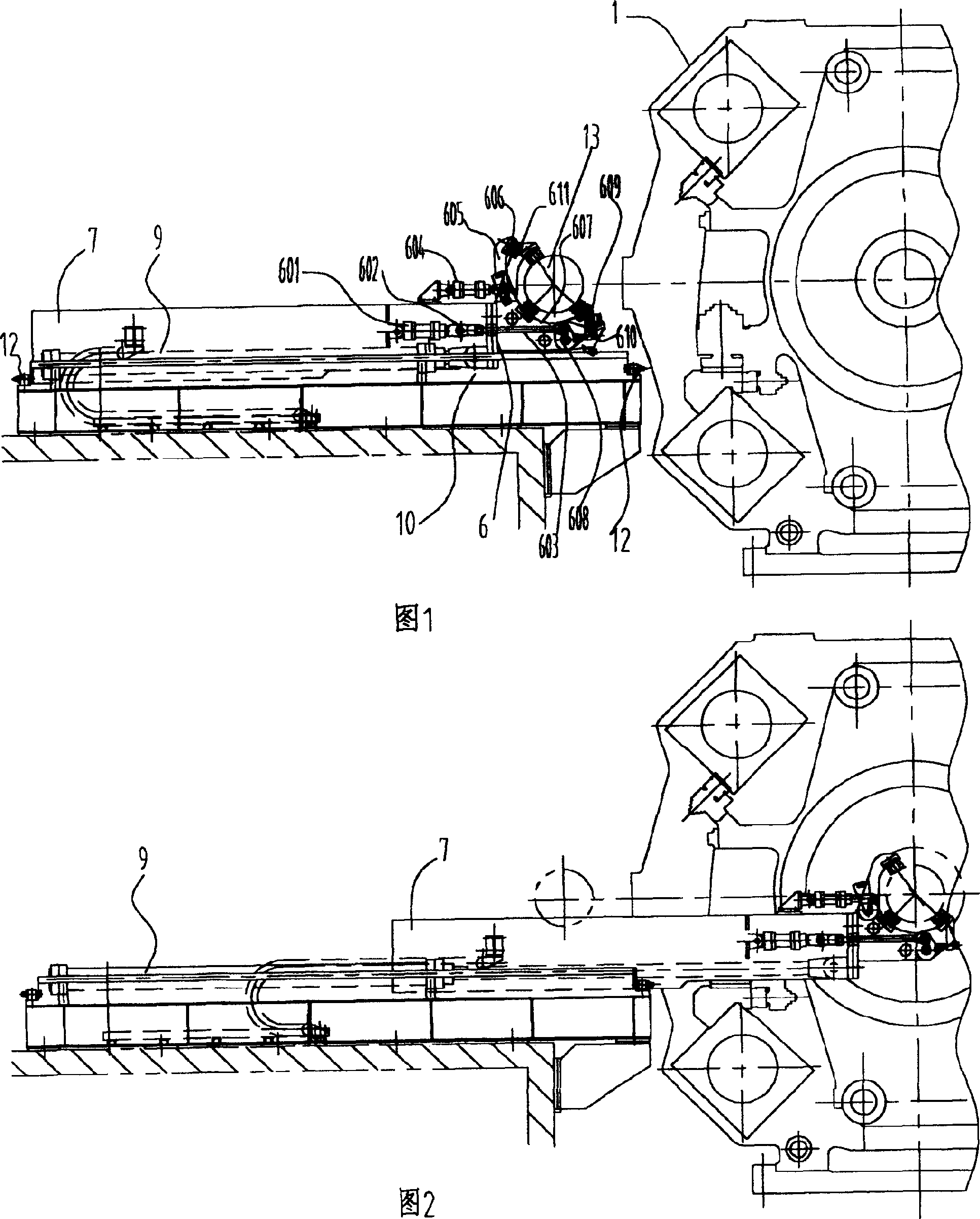

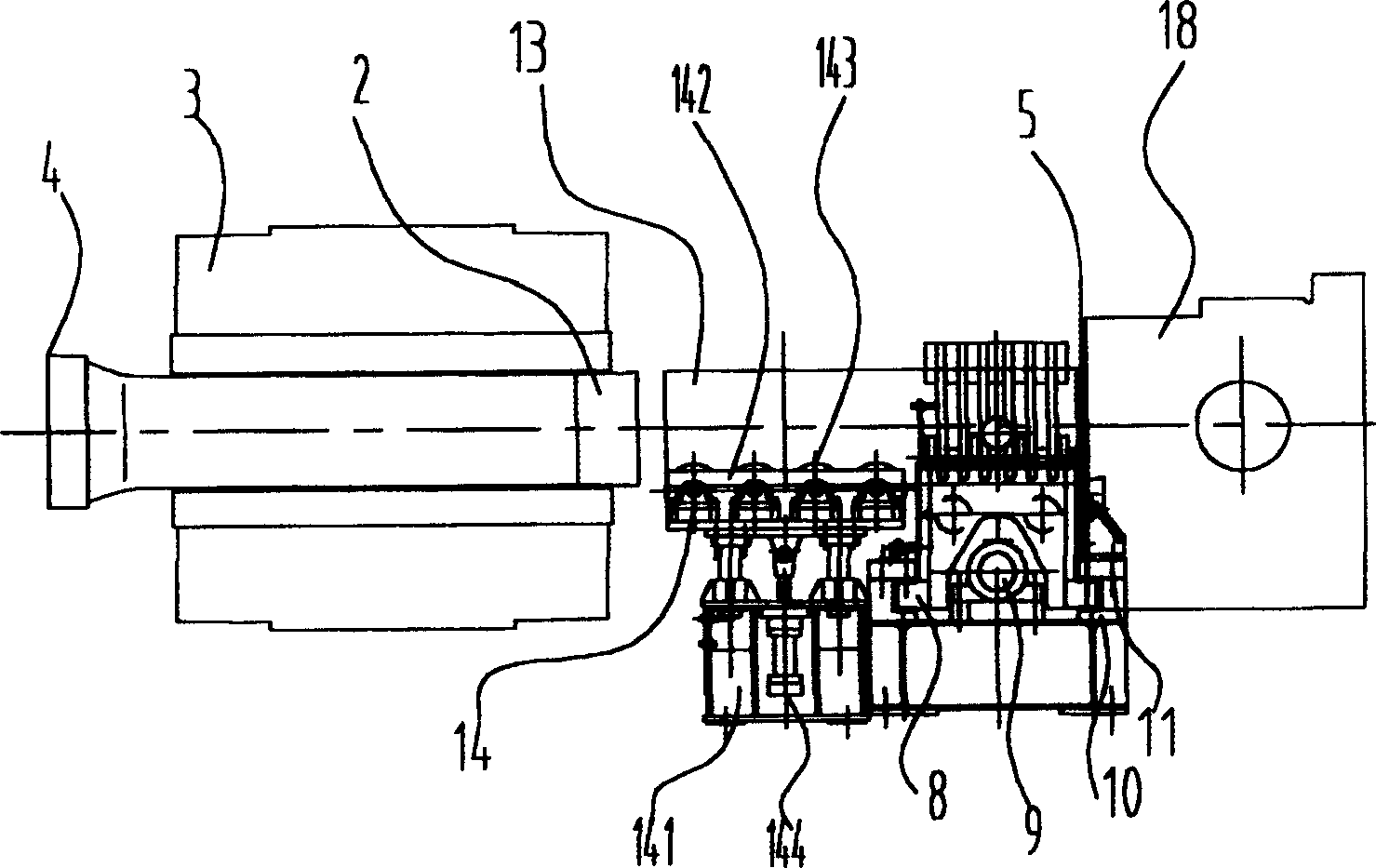

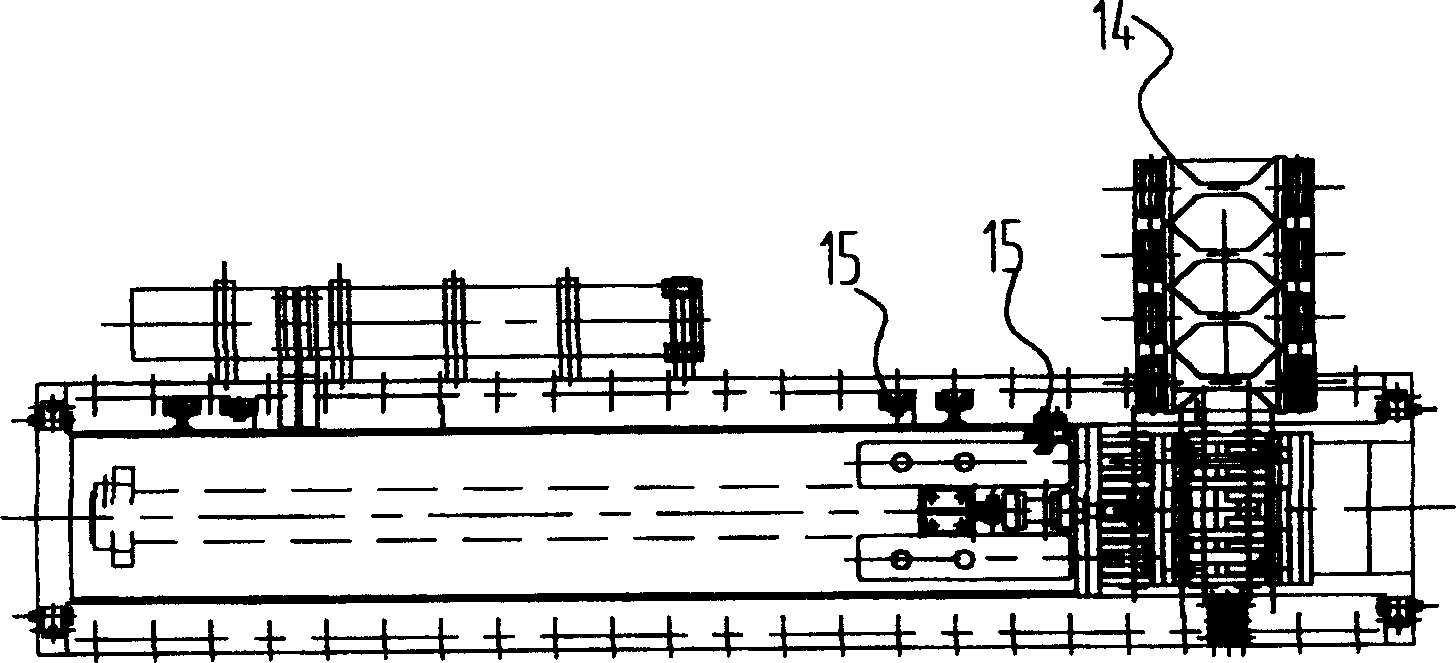

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

[0036] Figure 1 to Figure 4 As shown, the self-adaptive ingot feeding device of the front loading clamp of the short-stroke aluminum extrusion machine includes a hydraulic control device and an electrical control device; the aluminum extrusion machine 1 adopts a fixed extrusion pad 2 so that the extrusion cylinder 3 is covered Squeeze rod 4, and make both are in return state. The clamp-type self-adaptive ingot feeding device is arranged outside the center line of the extruder and close to the extension line of the end face of the mold 5 .

[0037] The clamp type self-adaptive ingot feeding device consists of manipulator 6, main arm 7 and slider 8, main arm oil cylinder 9, guide slide seat 10 and pressure plate 11; Inside, the main arm oil cylinder is installed on the guide slide seat, the head end of the guide slide seat is equipped with a limiter 12, and the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com