Method and apparatus for treating substrate

一种处理方法、处理装置的技术,应用在电气元件、半导体/固态器件制造、电路等方向,能够解决高分子化反应没有充分地进行等问题,达到缩短固化处理时间、消除等待时间、处理时间缩短的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

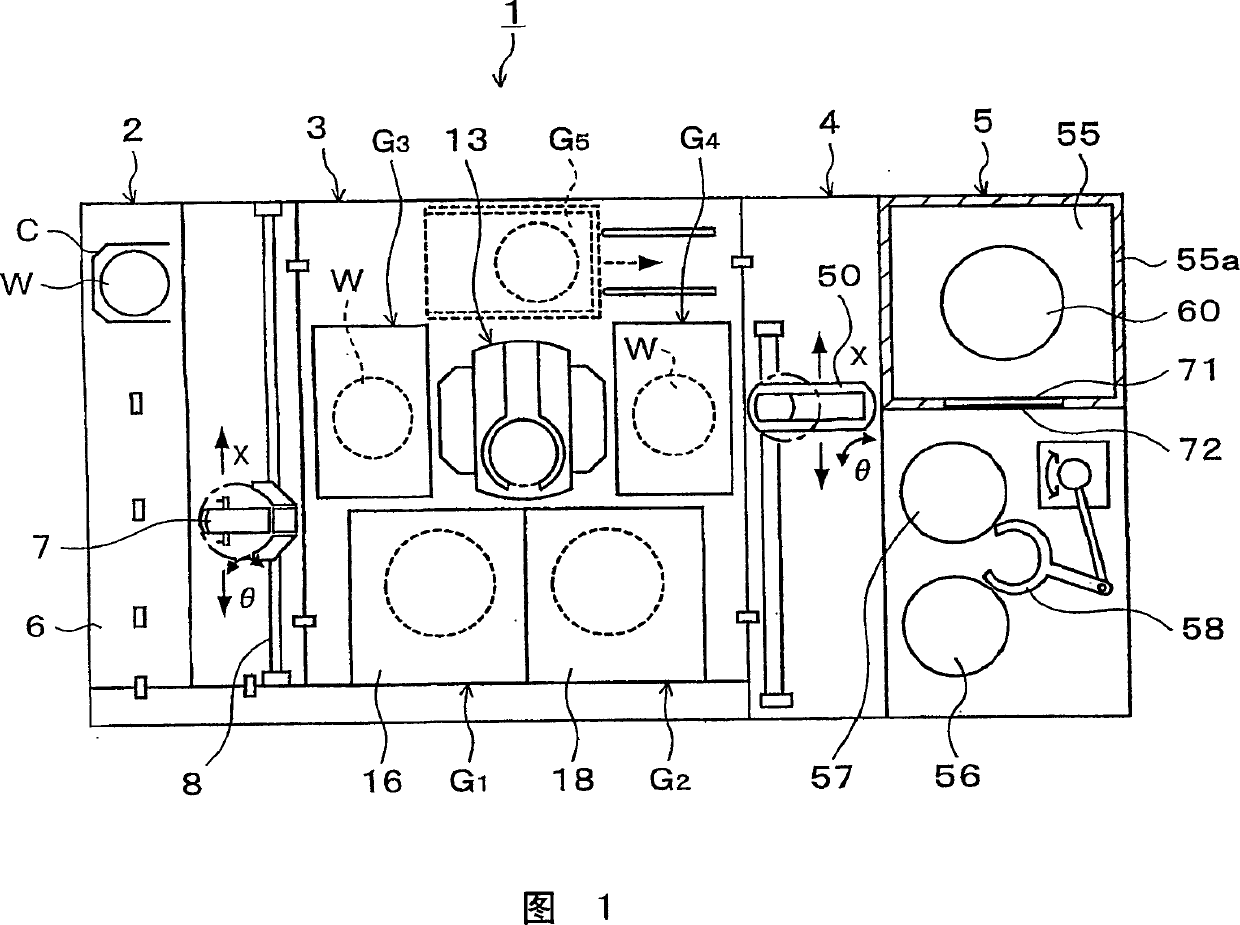

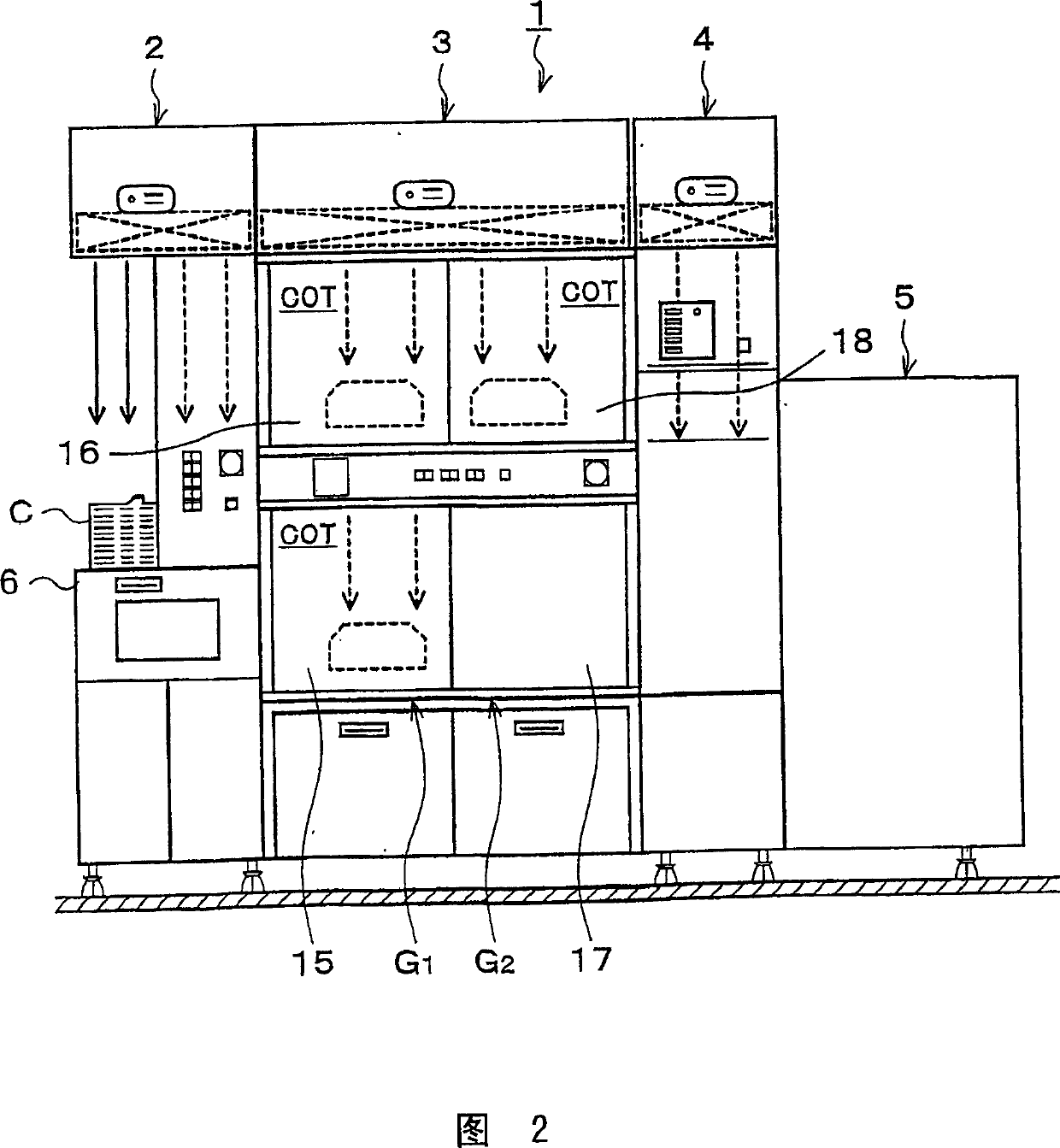

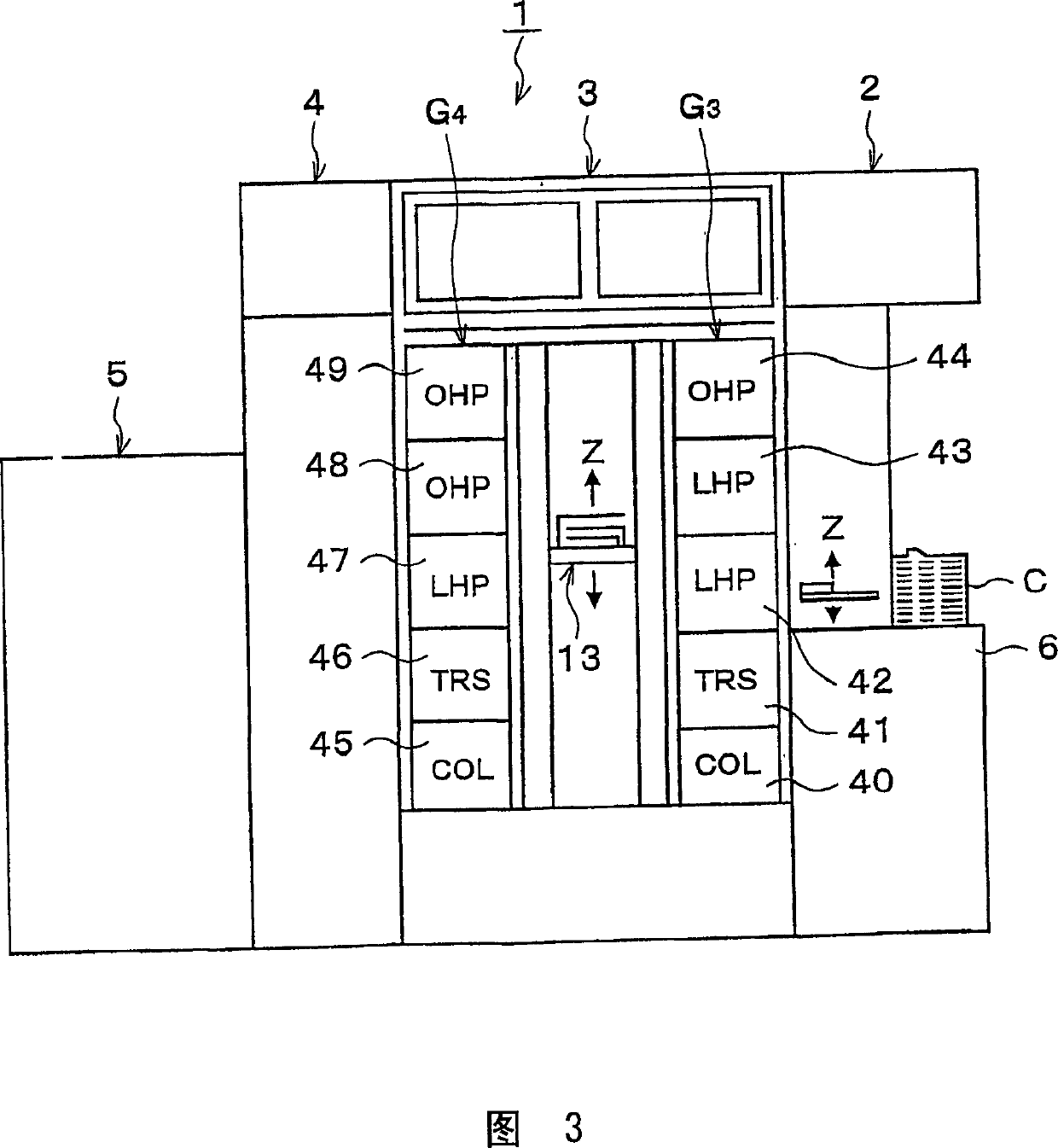

[0044] Next, preferred embodiments of the present invention will be described. 1 is a plan view schematically showing an insulating film forming apparatus 1 for implementing a wafer W processing method according to this embodiment, FIG. 2 is a front view of the insulating film forming apparatus 1 , and FIG. 3 is a rear view of the insulating film forming apparatus 1 .

[0045] As shown in FIG. 1, the insulating film forming apparatus 1 has, for example, a cassette station 2 for loading and unloading wafers W from the outside to the insulating film forming apparatus 1 or loading and unloading wafers W to and from cassette C in cassette units of, for example, 25 wafers W. The first processing station 3 of various processing units that performs predetermined processing individually in the insulating film forming process is provided adjacent to the first processing station 3, and the interface unit 4 that performs delivery of the wafer W, etc., and has a The second processing stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com