Fume cleaning regulating method and apparatus by indirect evaporating liquid utilizing the residual heat of fume

A flue gas waste heat and flue gas purification technology, applied in chemical instruments and methods, separation methods, solid separation, etc., can solve the problems of large heat exchanger equipment, insufficient smoke and dust contact, and large demand for cooling medium, and reduce Emission of inhalable particulate matter, long trouble-free operation time, and the effect of reducing flue gas flow under operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

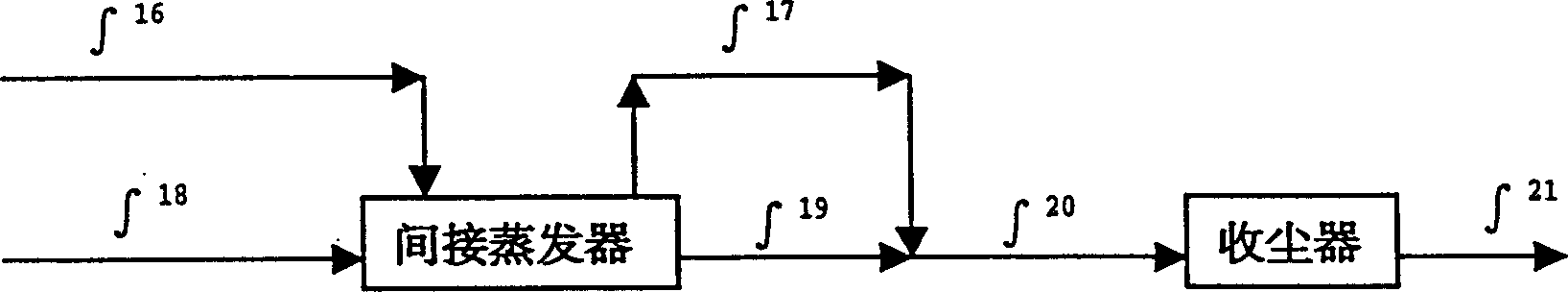

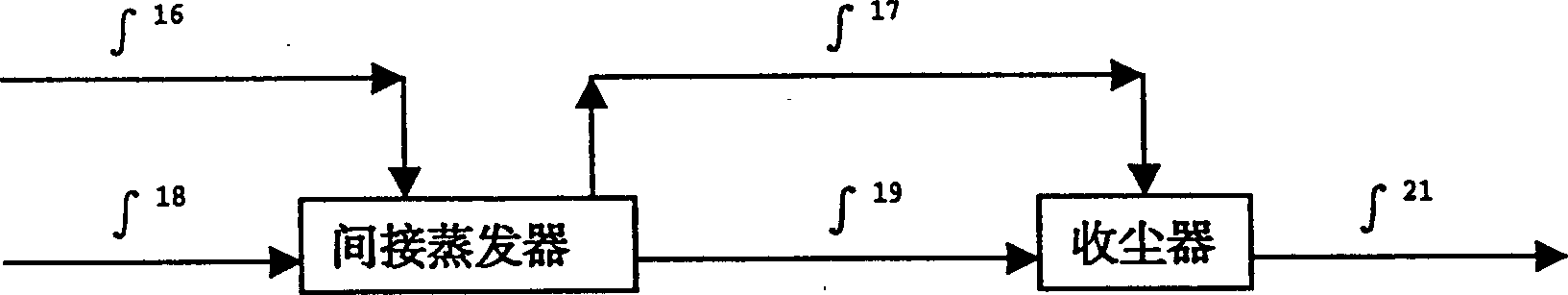

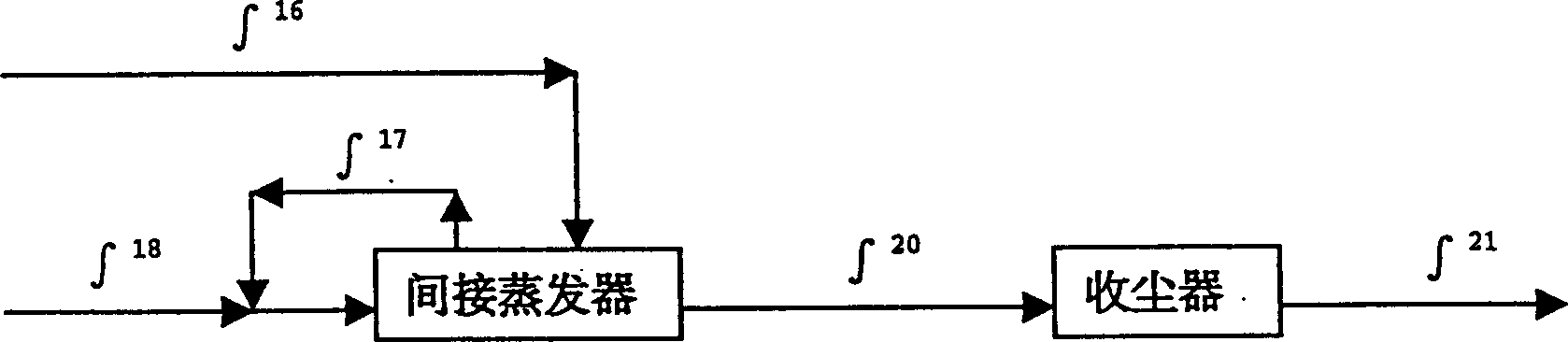

[0025] Such as Figure 1-4 As shown, a flue gas purification and tempering method that utilizes flue gas waste heat to indirectly evaporate liquid, the dust-laden hot flue gas 18 from the combustion source or heat utilization device flows through the heat source section 10 of the indirect evaporator, and passes through the heat source section 10 The heat conduction element group 5 that penetrates the heat source section 10 and the evaporation section container 1 and seals both absorbs heat from the hot dusty flue gas 18 flowing through the heat source section 10 and transfers it to the evaporation section 6, indirectly heats and evaporates at a certain liquid supply speed Supply the liquid 16 in the container 1 of the evaporation section. When the liquid 16 heats up and evaporates, it absorbs a large amount of latent heat of vaporization and the heat required for temperature rise from the dust-laden hot flue gas 18 through the heat conduction element group 5, so that the dust-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com