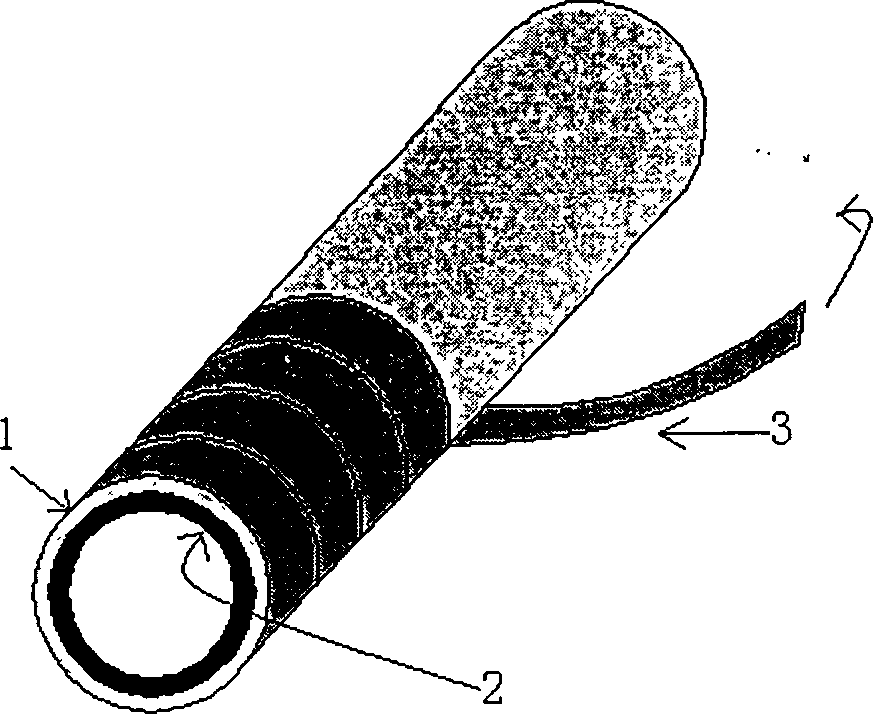

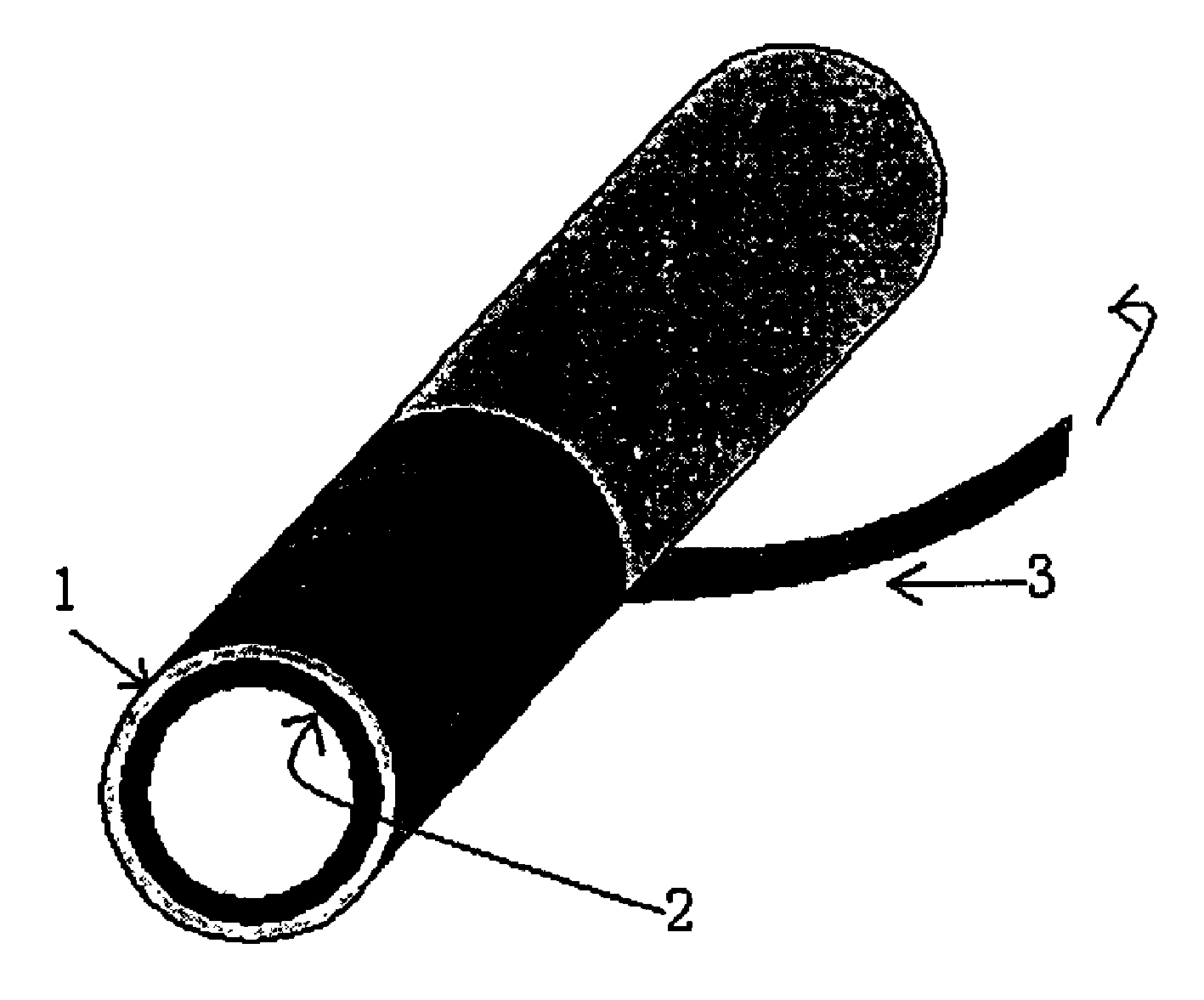

Polyhydroxy fatty acid ester blood vessel stent and making method thereof

A technology of polyhydroxyalkanoate and vascular stents, which is applied in the field of biomedical engineering, can solve the problems of poor affinity between blood vessels and cells, the degradation speed cannot match the tissue regeneration speed, and the mechanical properties and suturing performance need to be improved. Achieve the effects of improved cell adhesion, good biocompatibility, and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 80% polyhydroxybutyrate-valerate (PHB-HV) and 20% polyethylene glycol / polybutylene terephthalate (PEG-CO-PBT) copolymer blended to prepare a diameter of 8mm, a length of 50mm vascular stent.

[0033] (1) Preparation of blend solid film

[0034] ① Mix 80% polyhydroxybutyrate-valerate (PHB-HV) with 20% polyethylene glycol / polybutylene terephthalate (PEG-CO-PBT) and chloroform, heat in a water bath and fully Stir to prepare a solution with a uniform concentration of 0.05g / ml;

[0035] ②Using the method of cast film formation, cool the solution prepared in ① and pour it into a pair of petri dishes with a diameter of 10cm (the diameter is adjustable, the same below), and fasten the upper and lower evaporating dishes to let the chloroform volatilize naturally. Prepare a solid film, and control the amount of raw materials so that the film thickness is 1 to 2 mm;

[0036] (2) Preparation of blend porous membrane

[0037] ① Pass the salt through a standard sieve to select Na...

Embodiment 2

[0051] A vascular stent with a diameter of 3 mm and a length of 10 mm was prepared using 70% polyhydroxybutyrate (PHB) and 30% polyethylene glycol / polybutylene terephthalate (PEG-CO-PBT).

[0052] (1) Preparation of blend solid film

[0053] The preparation method is the same as the method for preparing the PHB-HV / PEG-CO-PBT solid film in Example 1, except that PHB-HV / PEG-CO-PBT is replaced by PHB / PEG-CO-PBT, wherein PHB accounts for 70%, PEG-CO-PBT accounts for 30%, the solution concentration is 0.03g / ml, and the diameter of the petri dish is adjusted to 6cm;

[0054] (2) Preparation of blend porous membrane

[0055] The preparation method is the same as the method for preparing the PHB-HV / PE-CO-PBT porous membrane in Example 1, except that PHB-HV / PEG-CO-PBT is replaced by PHB / PEG-CO-PBT, wherein PHB accounts for 70%, PEG-CO-PBT accounted for 30%, the added NaCl was 15 times the total mass of the blend, and the particle size of NaCl was adjusted to 200-300 μm; the diameter ...

Embodiment 3

[0061] Using 60% polyhydroxybutyrate-hexanoate (PHB-HH) and 40% polyethylene glycol / polybutylene terephthalate (PEG-CO-PBT) blend to prepare 100mm vascular stent.

[0062] (1) Blend solid film preparation

[0063] The preparation method is the same as the method for preparing the PHB-HV / PEG-CO-PBT solid film in Example 1, except that PHB-HV / PEG-CO-PBT is replaced by PHB-HH / PEG-CO-PBT, wherein PEG-CO -PBT accounts for 40% of the total mass, the solution concentration is 0.06g / ml, and the diameter of the petri dish is changed to 19cm;

[0064] (2) Preparation of blend porous membrane

[0065] The preparation method is the same as the method for preparing the PHB-HV / PEG-CO-PBT porous membrane in Example 1, except that PHB-HV / PEG-CO-PBT is replaced by PHB-HH / PEG-CO-PBT, wherein PEG-CO - PBT accounts for 40% of the total mass, the added NaCl is 20 times the total mass of the blend, and the particle size of NaCl is changed to 200-300 μm;

[0066] (3) Preparation of blend reinfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com