Combustion gas pipes house lead-in connecting equipment

A technology for gas pipelines and connecting devices, which is applied in the direction of pipes/pipe joints/fittings, pipes, branch pipelines, etc. Corrosion capability, reduction of hazards and impacts, effect of increased project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

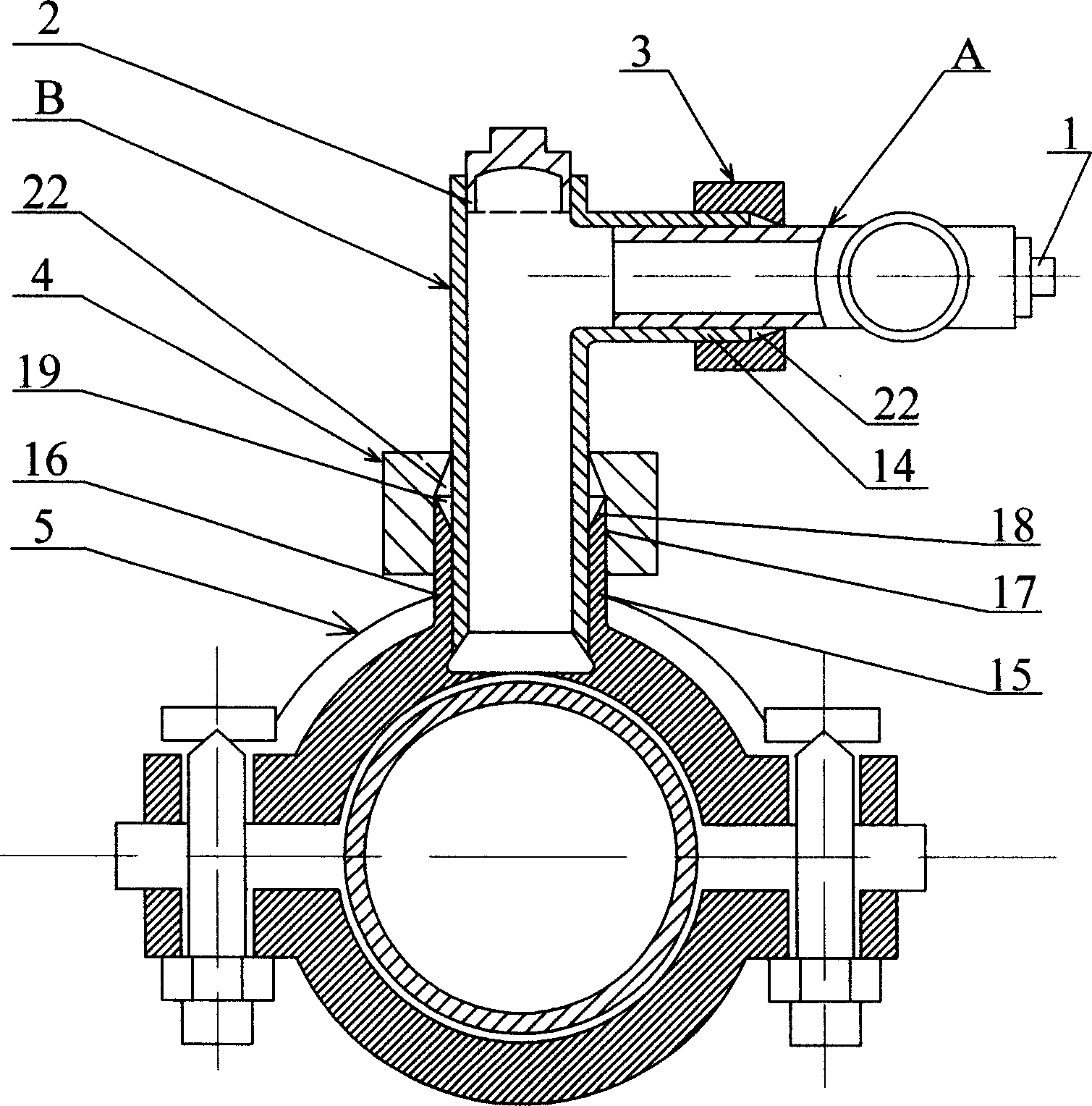

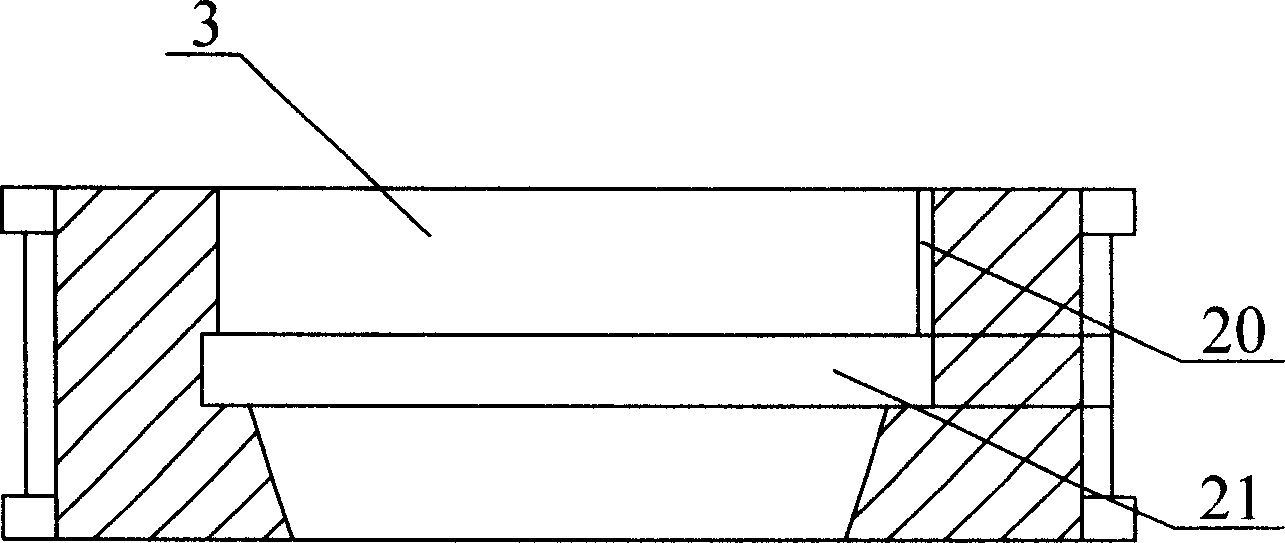

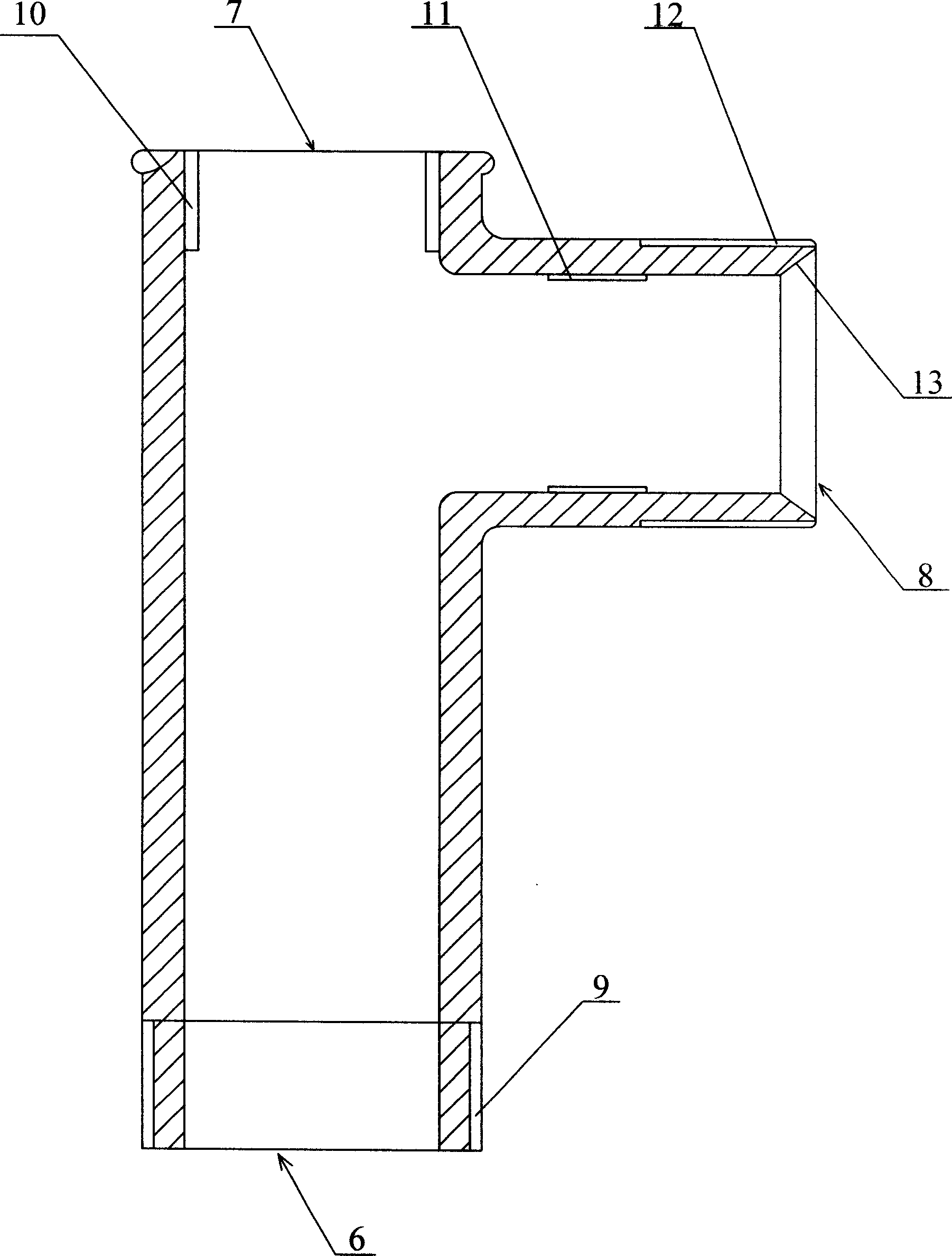

[0019] as attached figure 1 and figure 2 As shown, the gas pipeline inlet connection device of the present invention includes three-way pipe bodies A, B, lock nuts 3, 4 and fixed pipe clamp 5. The three-way body A and the three-way body B have the same structure, and both have an upper port 6, a lower port 7 and a side port 8, and the upper ports 6 of the three-way body A and B are respectively provided with external threads 9, and the lower ports The ports 7 are provided with internal threads 10 respectively, and the side ports 8 are respectively provided with internal threads 11 and external threads 12 . The inner wall edges of the side ports 8 of the three-way pipe body A and the three-way pipe body B have outwardly inclined trumpet-shaped grooves 13 , and a sealing ring 14 is embedded in the trumpet-shaped grooves 13 . The inner wall and the outer wall of the cylindrical pipe clamp 15 on the fixed pipe clamp 5 are respectively provided with internal threads 16 and exter...

Embodiment 2

[0021] The second embodiment is basically the same as the first embodiment, except that the inner wall of the upper port of the three-way pipe body A has an internal thread 23, and the three-way pipe body A is connected to the fixed pipe clamp 5 through a connecting pipe 24, and the connecting pipe body A One end of 24 is threadedly connected with the inner wall of cylindrical pipe clamp 15, and is locked by a lock nut 25 sleeved on the connecting pipe 24. A support ring 26 is housed in the lock nut 25, and the other end is connected with the tee pipe The inner wall of the body A is threaded and locked by the lock nut 27 sleeved on the connecting pipe 24. The lock nut 27 is equipped with a support ring 28 and a sealing ring 29.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com