Cross-linked shperical macroporous cellulose bead and clean preparing process by jetting method

A technology of cellulose and jetting method, which is applied to the preparation of macroporous cross-linked spherical cellulose beads by jetting and its cleaning process and the recovery of solvents, can solve the problem of restricting the development of spherical cellulose adsorbents, environmental pollution, and inability to use For the preparation of cellulose beads and other issues, to broaden the development approach, reduce production costs, and improve the effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

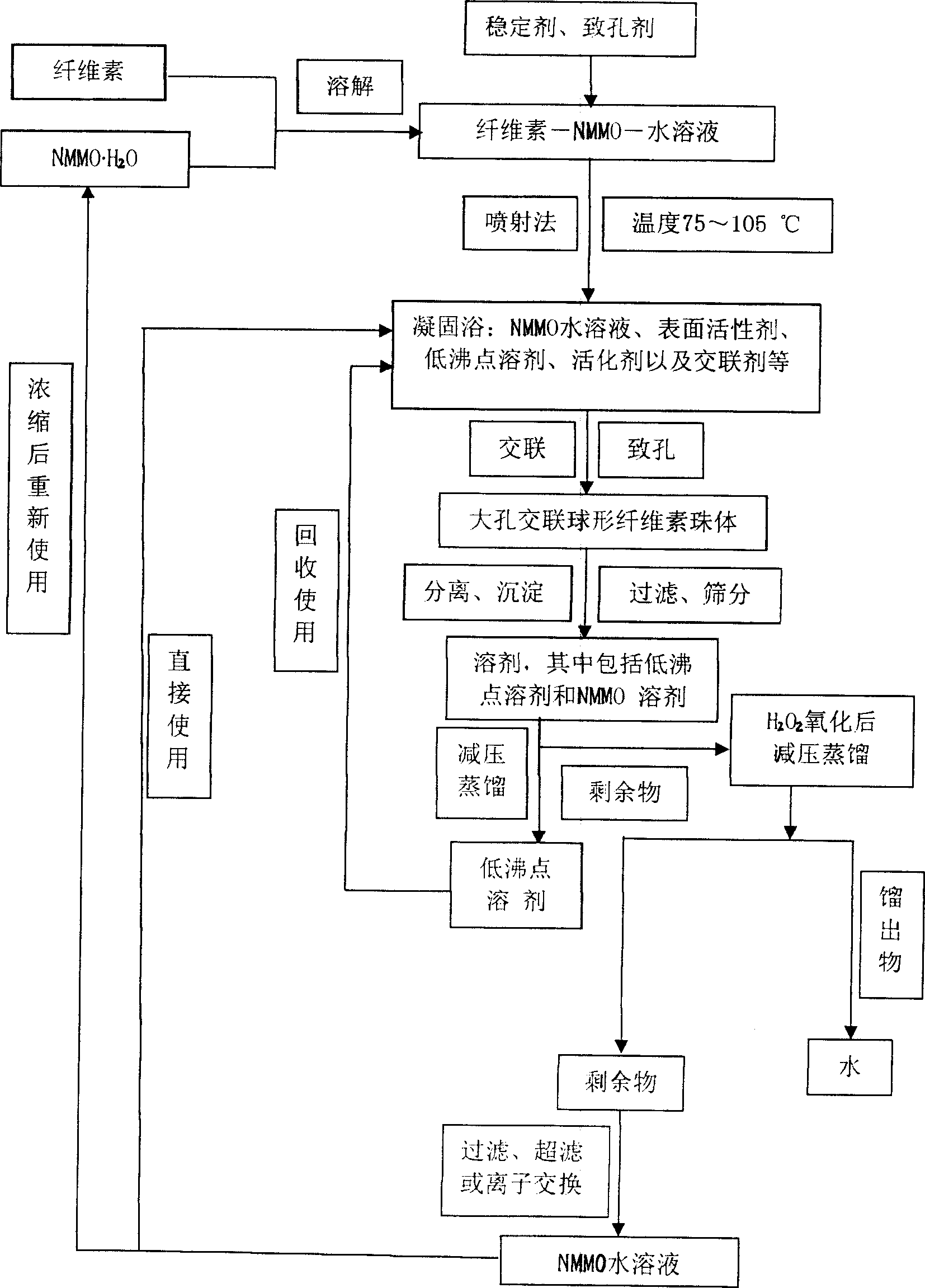

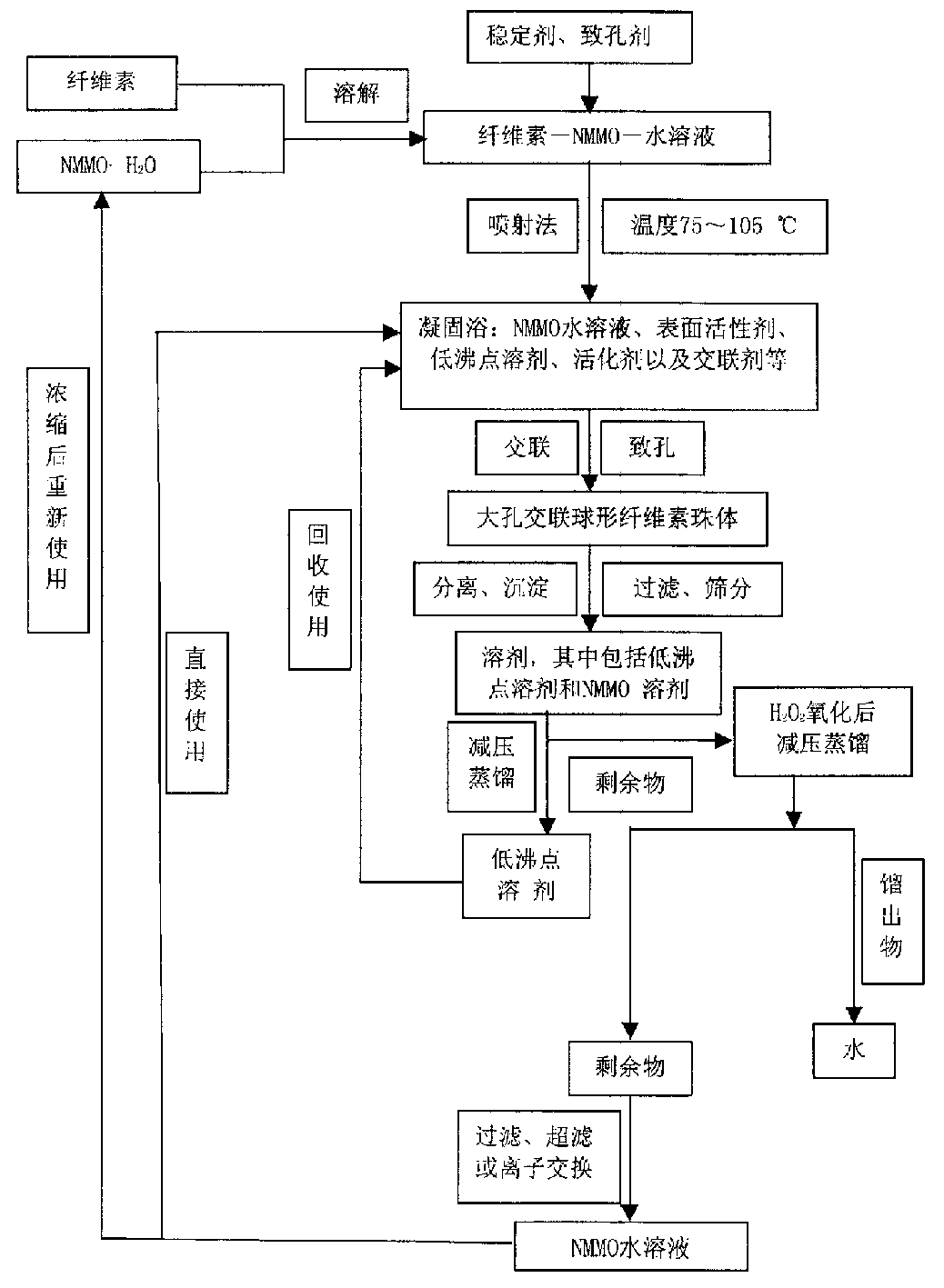

[0043] Embodiment 1: the process steps and order of the present embodiment are as figure 1 shown. Specific steps are as follows:

[0044] (1) dissolve

[0045] Raw materials and formula (unit-kilogram) of the present embodiment:

[0046] Cotton linters: 2.0 kg

[0047] NMMO·H 2 O: 95 kg

[0048] Stabilizer (mixture of oxalic acid and isoascorbic acid, mass ratio 4:1): 1 kg

[0049] Porogen (calcium carbonate): 2 kg

[0050] Dissolving process steps and process parameters: 2.0 kg of pulp or cotton is put into a reactor containing 95 kg of N-methylmorpholine-N-oxide (N-methylmorpholine-N-oxide, NMMO) aqueous solution, and the reaction temperature Controlled at 75°C, dissolved and reacted for 90 minutes to form a cellulose-NMMO-water solution with a mass fraction of 2.06%, then added 1 kg of a stabilizer of a mixture of oxalic acid and isoascorbic acid and 2 kg of a calcium carbonate porogen. This process step is carried out under normal pressure.

[0051] (2) Spraying, ...

Embodiment 2

[0062] Embodiment 2: the process steps and order of the present embodiment are as figure 1 shown. Specific steps are as follows:

[0063] (1) dissolve

[0064] Raw materials and formula (unit-kilogram) of the present embodiment:

[0065] Deinked waste paper pulp: 1.0 kg

[0066] NMMO·H 2 O: 97 kg

[0067] Stabilizer (mixture of oxalic acid and isoascorbic acid, mass ratio 7:1): 0.5 kg

[0068] Porogen (sodium carbonate): 1.5 kg

[0069] Dissolving process steps and process parameters: put the above-mentioned amount of pulp or cotton into the reactor containing the above-mentioned amount of N-methylmorpholine-N-oxide (N-methylmorpholine-N-oxide, NMMO for short) aqueous solution, and The reaction temperature was controlled at 65°C, and the dissolution reaction was carried out for 120 minutes to form a cellulose-NMMO-water solution with a mass fraction of 1.02%, and then the above-mentioned amount of stabilizer and porogen was added. This process step is carried out under...

Embodiment 3

[0081] Embodiment 3: the process steps and order of the present embodiment are as figure 1 shown. Specific steps are as follows:

[0082] (1) dissolve

[0083] Raw materials and formula (unit-kilogram) of the present embodiment:

[0084] Masson pine bleached pulp: 4.0 kg

[0085] NMMO·H 2 O: 91 kg

[0086] Stabilizer (methyl ethyl ketoxime and its mixture, mass ratio 32:1): 2.0 kg

[0087] Porogen (sodium bicarbonate): 3.0 kg

[0088] Dissolving process steps and process parameters: put the above-mentioned amount of pulp or cotton into the reactor containing the above-mentioned amount of N-methylmorpholine-N-oxide (N-methylmorpholine-N-oxide, NMMO for short) aqueous solution, and The reaction temperature was controlled at 85°C, and the dissolution reaction was carried out for 80 minutes to form a cellulose-NMMO-water solution with a mass fraction of 4.21%, and then the above-mentioned amount of stabilizer and porogen was added. This process step is carried out under no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com