Method for preparing copper base electrode powder deformation compound material

A composite electrode and powder technology, which is applied in the field of composite material preparation, can solve the problems of low material density, poor two-phase combination, and difficulty in engineering application due to large deformation requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

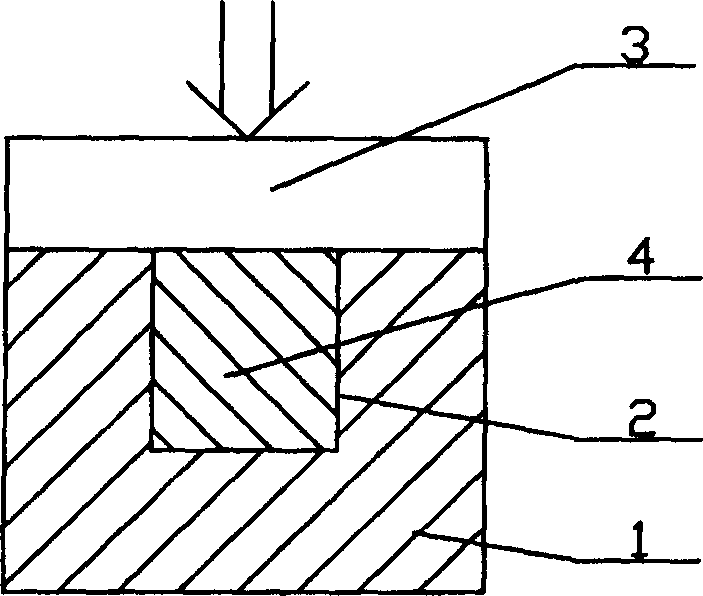

[0005] Specific implementation mode 1: In this implementation mode, elemental Cu and Cr powders are used as raw materials, and the ratio thereof is Cu85Wt%; Cr15Wt%. The specific steps are as follows:

[0006] 1. Cu and Cr elemental powders are plastically deformed by high-energy mechanical ball milling at 400rpm for 3 hours to obtain Cu / Cr lamellar composite powders, and the lamellar size is below 3 μm. In the self-made MJ-1 type agitating high-energy ball mill, GCrl5 steel balls of 6 mm are used, the ball-to-material ratio is 8:1, the rotation speed is 400 rpm, the amount of balls (ball volume / barrel volume) is 0.2, and vacuum hydrogen is used for protection. cool down. The ball milling time is 3 hours.

[0007] 2. The Cu / Cr composite powder is cold-pressed at 900 MPa to obtain a billet with a relative density of about 85%, and vacuum sintered at 900-950°C for 1 hour to obtain a sintered billet with a relative density of about 97%.

[0008] 3. The sintered billet is prehe...

specific Embodiment approach 2

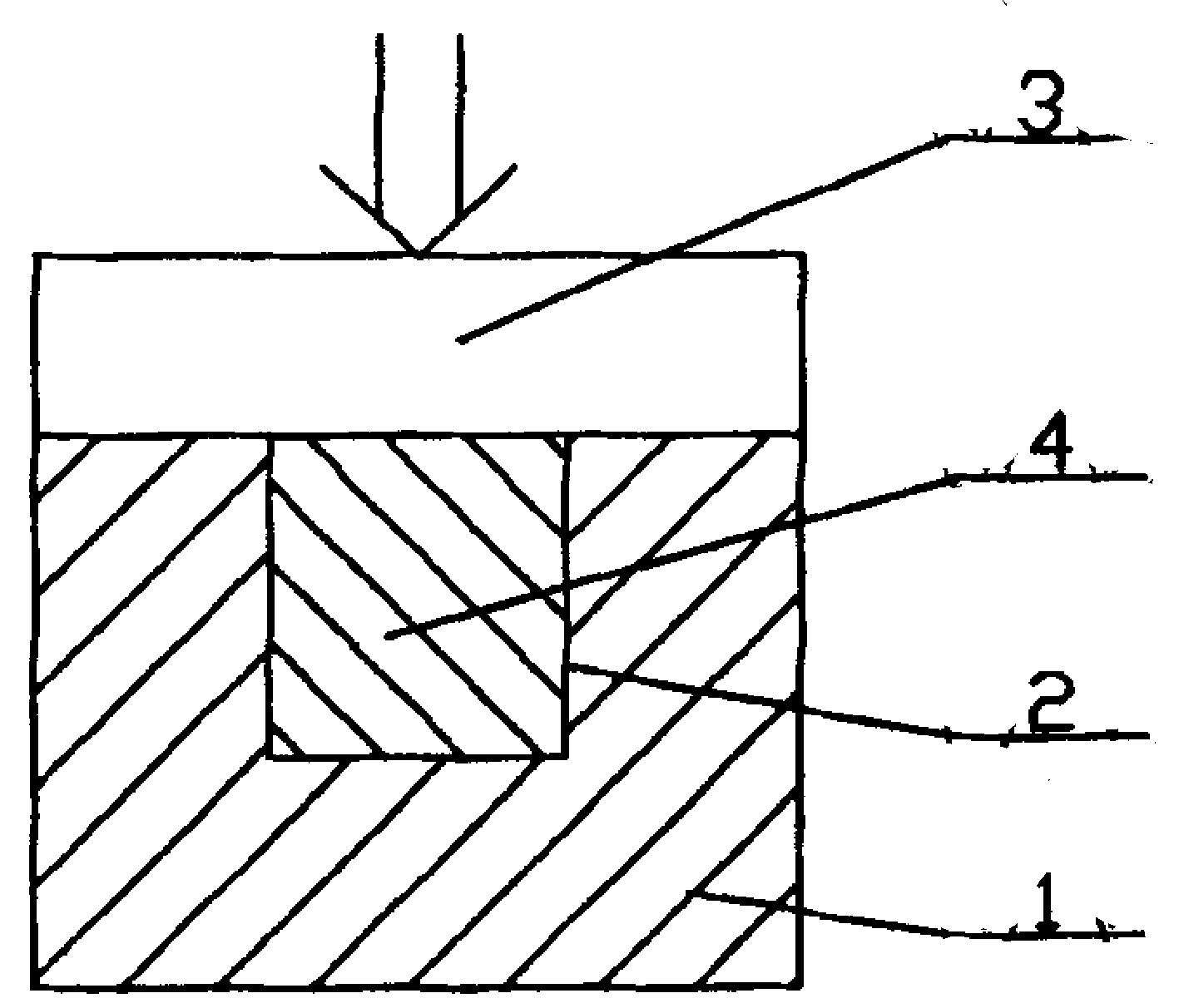

[0011] Embodiment 2: In this embodiment, simple W and Cu powder are used as raw materials, and the ratio thereof is W60Wt%; Cu40Wt%. The specific steps are as follows:

[0012] 1. W / Cu composite powder is obtained by plastic deformation of W and Cu elemental powder at 400 rpm for 60 hours with high-energy mechanical ball milling, and the particle size is below 4 μm. Then in the self-made MJ-1 type agitation type high-energy ball mill ball mill, adopt GCrl5 steel ball 6mm, ball material ratio 2: 1, rotating speed 400rpm, ball capacity (ball volume / barrel volume) 0.2, adopt vacuum to fill argon gas protection, Circulating water cooling. The ball milling time is 60 hours.

[0013] 2. The W / Cu composite powder is cold-pressed at 900 MPa to obtain a billet with a relative density of about 85%, and vacuum sintered at 900°C to 1000°C for 4 hours to obtain a sintered billet with a relative density of about 97%.

[0014] 3. The sintered billet is preheated at 700°C to 950°C for 15 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com