Method for raising resistance of Ti3AlC2 and Ti2AlC and their composite materials to molten salt corrosion

A composite material, anti-melting technology, applied in the field of anti-corrosion of molten salt, can solve problems such as poor thermal corrosion resistance, and achieve the effect of improved anti-corrosion of molten salt and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

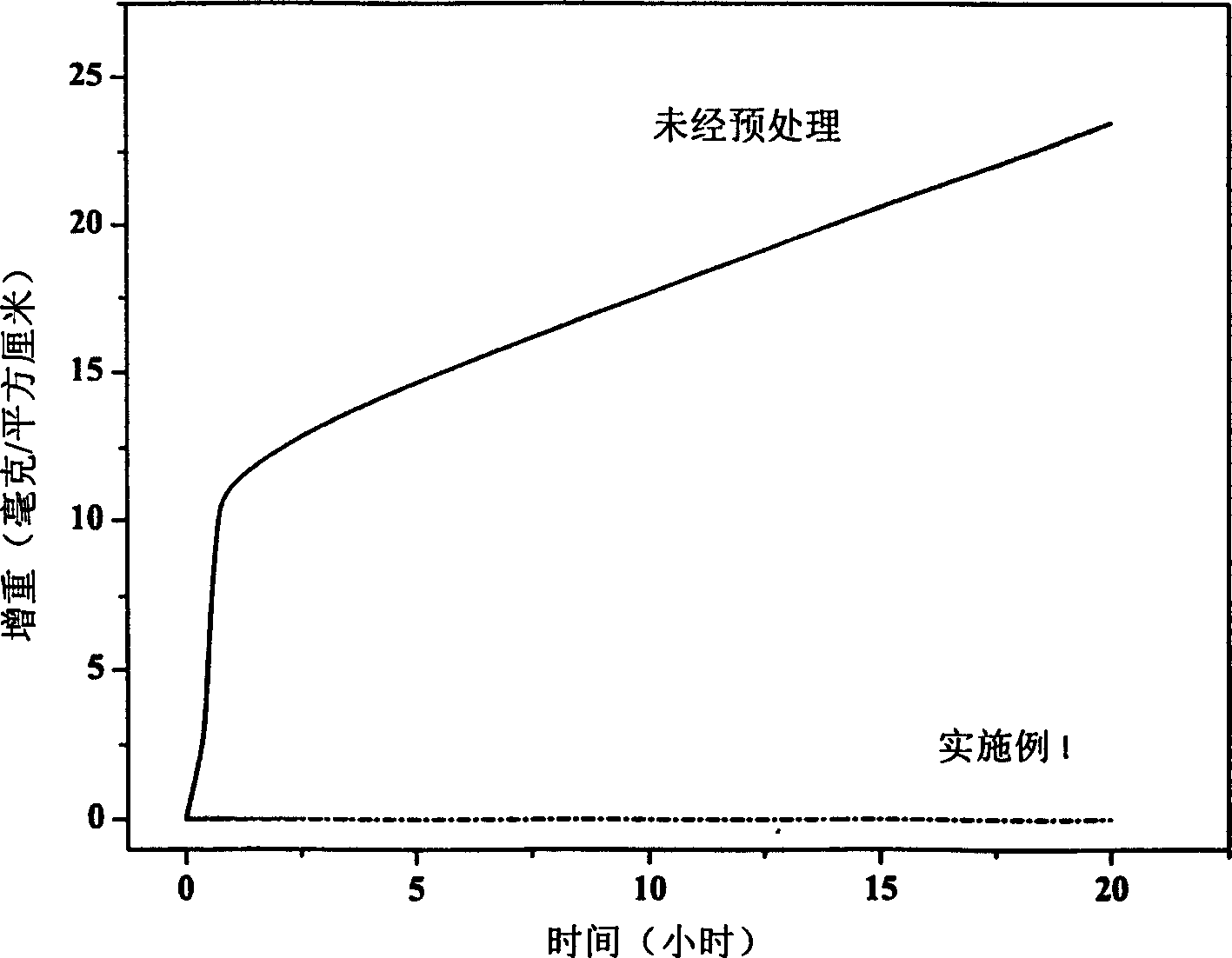

[0020] Polished Ti 3 AlC 2 The bulk polycrystalline material was surface treated in still air at 980°C for 2 hours, and a dense oxide film was formed on the substrate after surface modification (see figure 1 ). Resistance to molten Na after surface modification 2 SO 4 The effect of corrosion is evaluated by the relationship between corrosion weight gain and exposure time measured by thermobalance. Compared with the sample without surface modification treatment, the sample after surface modification in air at 980 ° C for two hours is under air atmosphere Melting Na at 900°C 2 SO 4 Medium corrosion for 20 hours without weight gain (see figure 2 ), which shows that the sample after air surface modification treatment at 980 °C has excellent resistance to melting Na 2 SO 4 Corrosive; the sample without pre-oxidation treatment melts Na at 900 °C under air atmosphere 2 SO 4 After 20 hours of medium corrosion, the weight gain per unit area is 23.5mg / cm 2 , the corrosion la...

Embodiment 2

[0022] Polished Ti 2 AlC is placed in a tube furnace with a temperature controlled at 1160°C, and flowing air is introduced for 1 hour. Compared with the sample without surface modification treatment, the sample after surface modification treatment in air at 1160°C is in the air atmosphere Corrosion in molten NaCl at 900°C for 20 hours has no weight gain, which indicates that the protective oxide film formed after surface modification in flowing air at 1160°C avoids Ti 2 Reaction of AlC with molten NaCl.

Embodiment 3

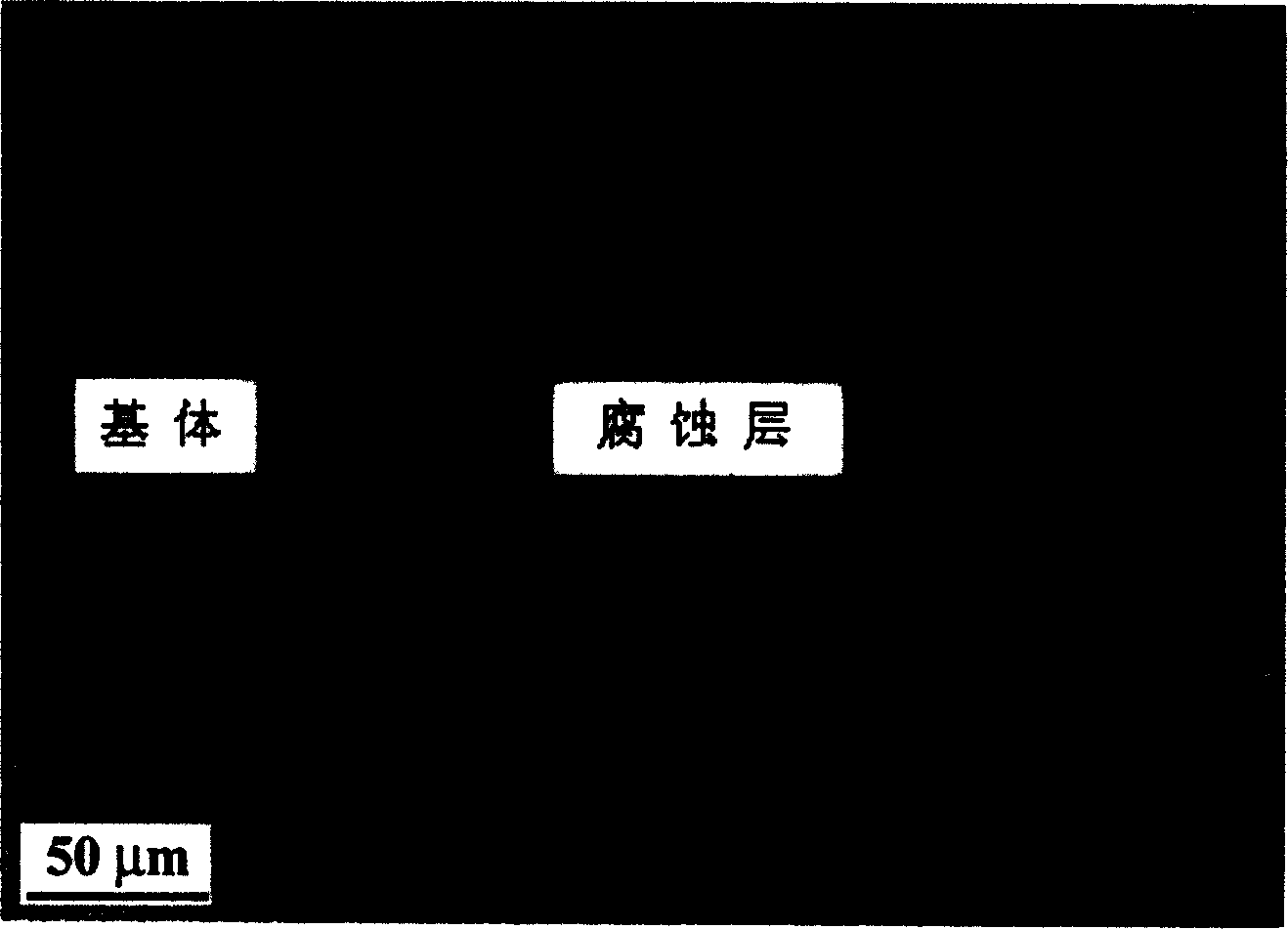

[0024] Polished Ti 3 AlC 2 / Ti 2 AlC composites were surface treated in diluted oxygen at 950°C for 0.5 hours, and the partial pressure of oxygen was 0.1 atmosphere. After surface modification, a dense oxide film was formed on the substrate, and after surface modification, it was resistant to melting K 2 SO 4 Corrosivity has been greatly improved, and the sample after surface modification treatment in 950°C diluted oxygen for 0.5 hours was melted at 1000°C in air atmosphere K 2 SO 4 There is no weight gain after being corroded for 20 hours, which shows that the sample after oxygen surface modification treatment at 950 °C has excellent anti-melting K 2 SO 4 Corrosive; samples without surface modification are melted at 1000°C in air atmosphere K 2 SO 4 After 20 hours of corrosion, the corrosion layer is very thick, about 500 μm (see Figure 4 ), and the corroded layer of the sample after surface modification treatment is almost indistinguishable from that before corrosio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com