Preparation method of spherical spinel powder for thermal spraying

A spinel powder, thermal spraying technology, applied in coating, melting spraying, metal material coating process and other directions, can solve the problems of complex process and achieve the effect of improving the corrosion resistance of molten salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

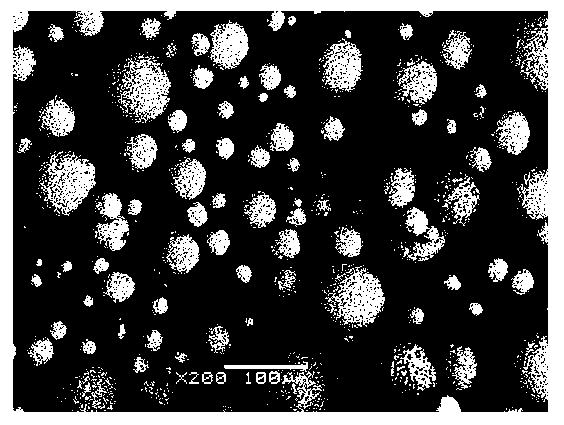

[0030] Weigh 20 kg NiFe 2 o 4 Powder, 200 g glycerin, 100 g sodium citrate, and 30 kg deionized water were placed in a vertical stirring mill and stirred at 200 r / min for 2 h to obtain a slurry with a solid content of 40% and stable suspension. After the slurry is prepared, pressure-type spray granulation is carried out, the inlet air temperature is 400°C, the outlet air temperature is 150°C, the spray pressure is 0.5 Mpa, and the yield is greater than 80%. The scanning photo of gained granulated powder is as figure 1 It can be seen from the figure that the shape of the product is spherical, the particle size is between 10 and 150 μm, the D50 of the product is 41.97 μm, the D90 is 129.60 μm, and the bulk density is 0.8 g / cm 3 .

Embodiment 2

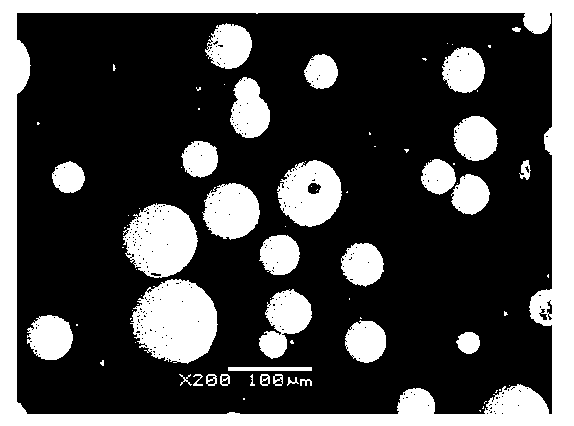

[0032]Weigh 20 kg NiAl 2 o 4 Powder, 100 g of paraffin, 40 g of polyacrylamide, and 13.33 kg of deionized water were placed in a vertical stirring mill and stirred at 200 r / min for 2 h to obtain a slurry with a solid content of 60% and stable suspension. After the slurry is prepared, pressure-type spray granulation is carried out, the air inlet temperature is 180°C, the outlet air temperature is 80°C, the spray pressure is 2.0 Mpa, and the yield is greater than 78%. The scanning photo of gained granulated powder is as figure 2 It can be seen from the figure that the shape of the product is spherical, the particle size is between 20 and 120 μm, the D50 of the obtained product is 53.76 μm, the D90 is 114.34 μm, and the bulk density of the product is 1.49 g / cm 3 .

Embodiment 3

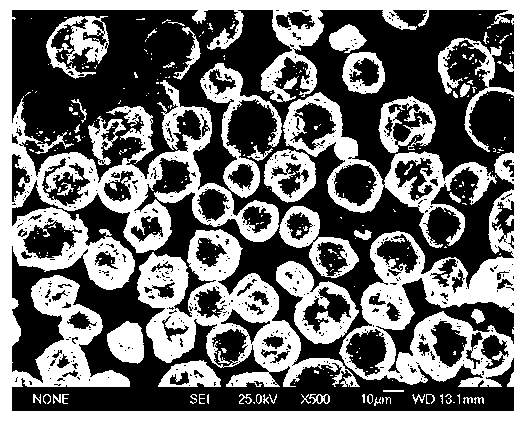

[0034] Weigh 10 kg ZnAl 2 o 4 Powder, 10 kg NiFe 2 o 4 , 400 g polyvinyl alcohol, 200 g carboxymethyl cellulose, and 8 kg ethanol were placed in a vertical stirring mill and stirred at 200 r / min for 2 h to obtain a slurry with a solid content of 70% and stable suspension. After the slurry was prepared, the centrifugal spray granulation was carried out, the air inlet temperature was 300°C, the outlet air temperature was 120°C, the atomizer speed was 30000 r / min, the peristaltic pump speed was 100 r / min, and the yield was greater than 90%. The scanning photo of gained granulated powder is as image 3 It can be seen from the figure that the appearance of the product is spherical, the particle size is between 10 and 50 μm, the D50 of the product is 37.82 μm, the D90 is 46.50 μm, and the bulk density of the product is 2.5 g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com