Method for copying gradation recording type read only CD

A recording method and technology for copying methods, which are applied in the manufacture of optical record carriers, optical record carriers, and photoengraving processes of pattern surfaces, etc., can solve the problems of inability to use read-only optical disks for copying, etc., and achieve the effect of solving copying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

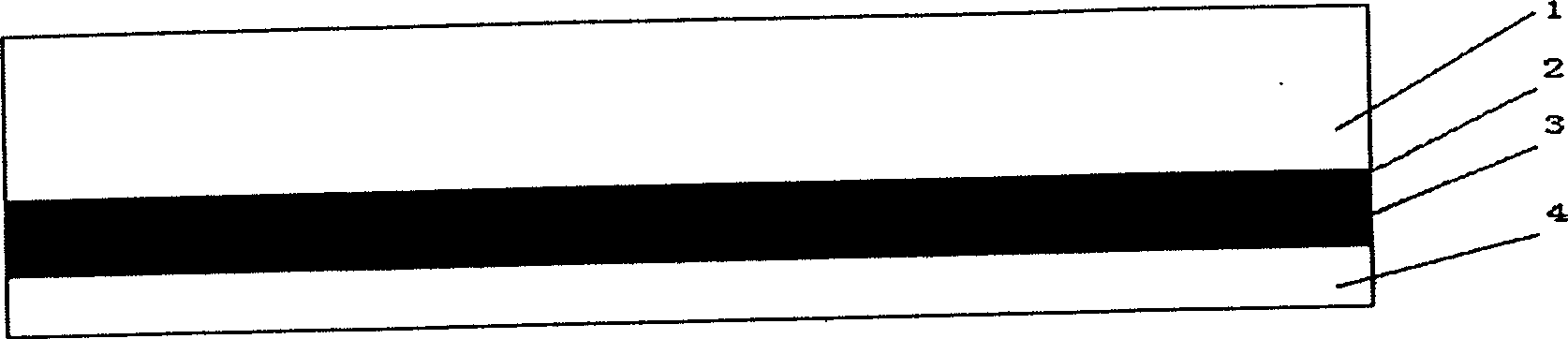

[0025] please see figure 1 : 1 is a disc, 2 is an information recording layer, 3 is a reflective layer, and 4 is a protective layer. The information recording layer 2 is made of a photosensitive material. The information recording layer of the multi-wavelength multi-level read-only optical disc has been fixed by strong electricity or other methods during duplication, and will not change due to light.

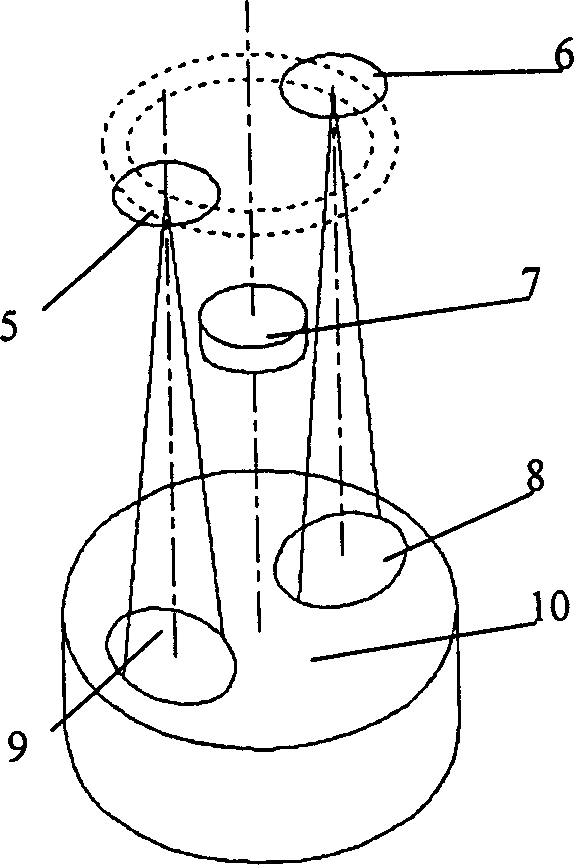

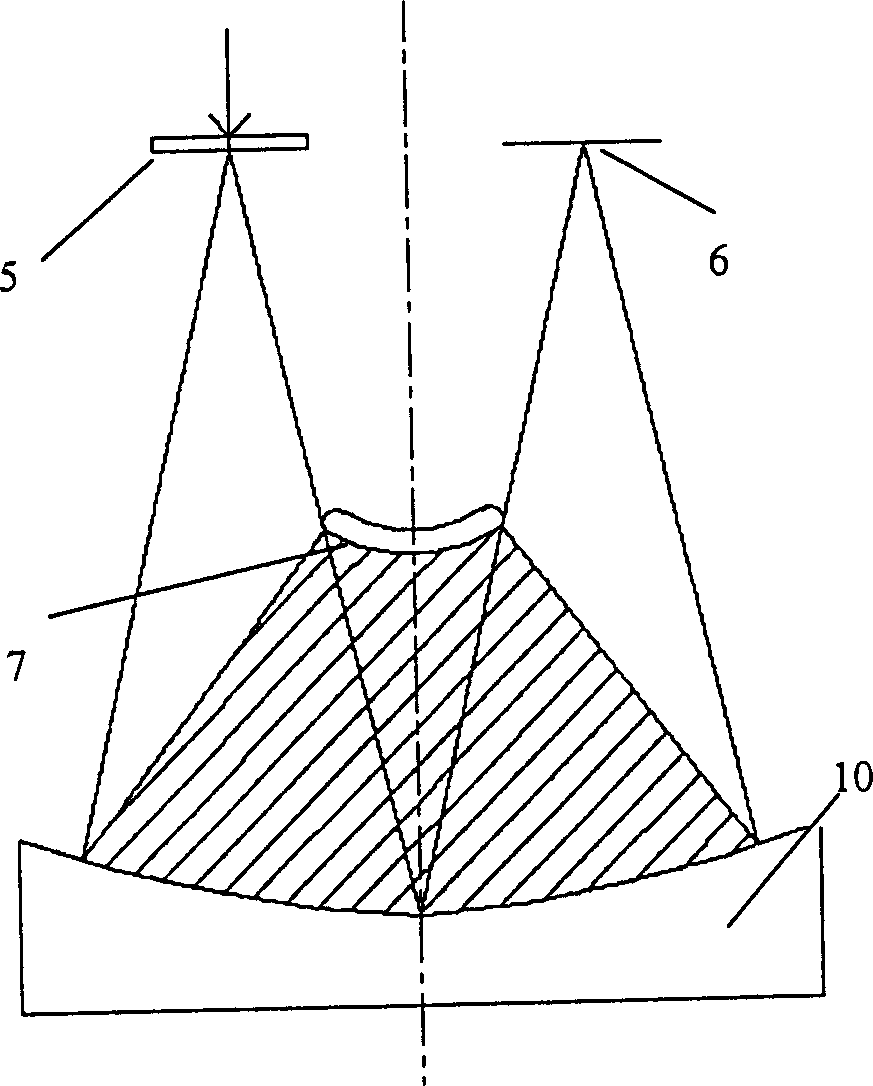

[0026] Figure 2-4 Among them, 5 is the master disc used as a mask, 6 is the disc to be copied composed of the photosensitive layer and the disc base, 7 is the auxiliary mirror (convex mirror, the mirror face is downward), 8, 9 are 5, 6 are in 10 The reflection spot formed on the top, 10 is the main reflector (concave mirror, the mirror surface is upward). 12 is the image formed by 11 on the disc to be copied. The light emitted by the exposure light source is irradiated downward from above the mask to form a projection 11 on the master disc. Since the master disc is a light...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com