Spheroidal graphite cast iron mould cavity inoculation block and its production technology

A technology of nodular cast iron and technology, which is applied in the field of nodular cast iron inoculation block and its production technology, which can solve the problems of high density, uneven inoculation, non-inoculation, etc., and achieve the effect of reducing contact reaction time and preventing nodularization decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

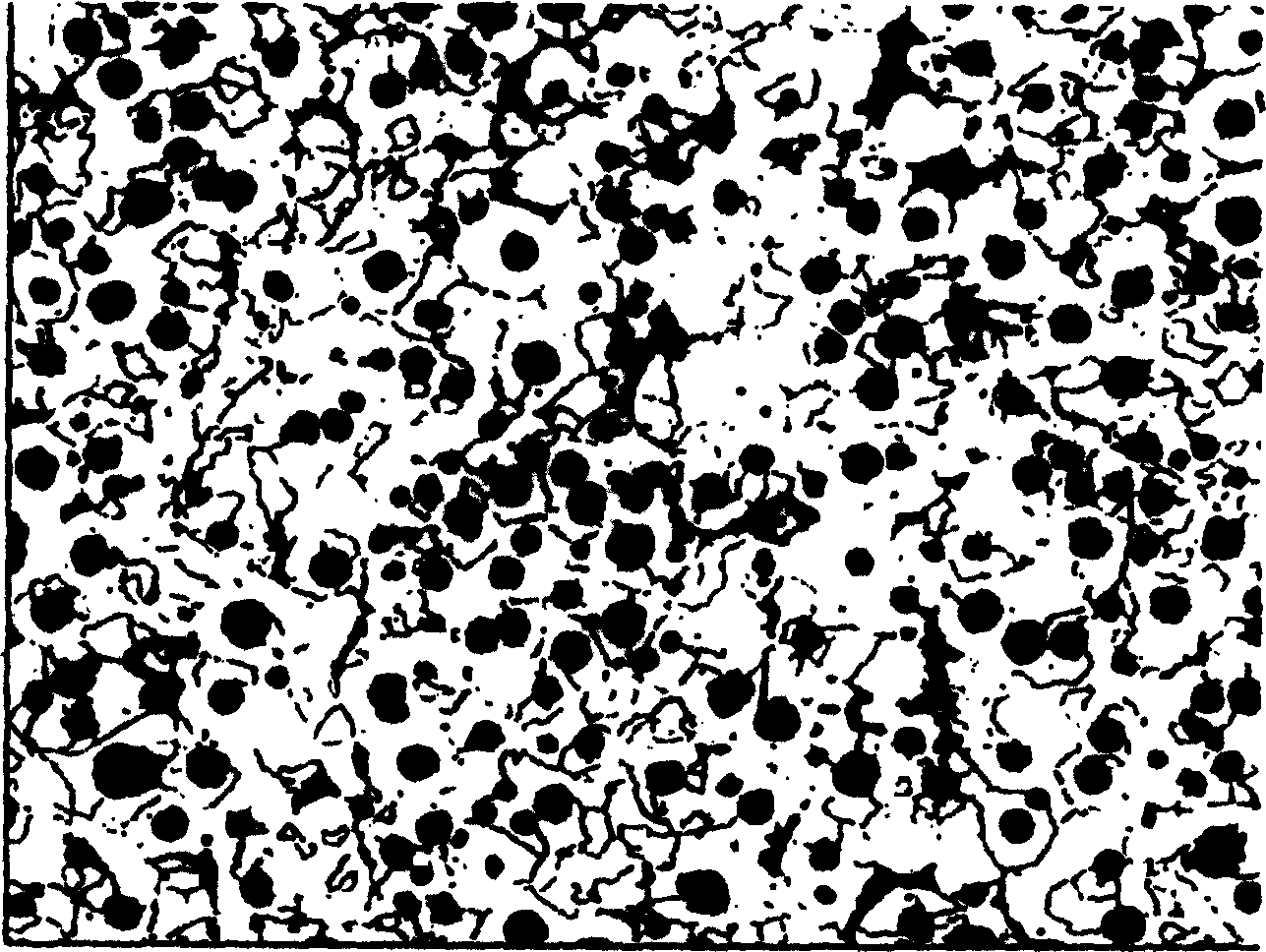

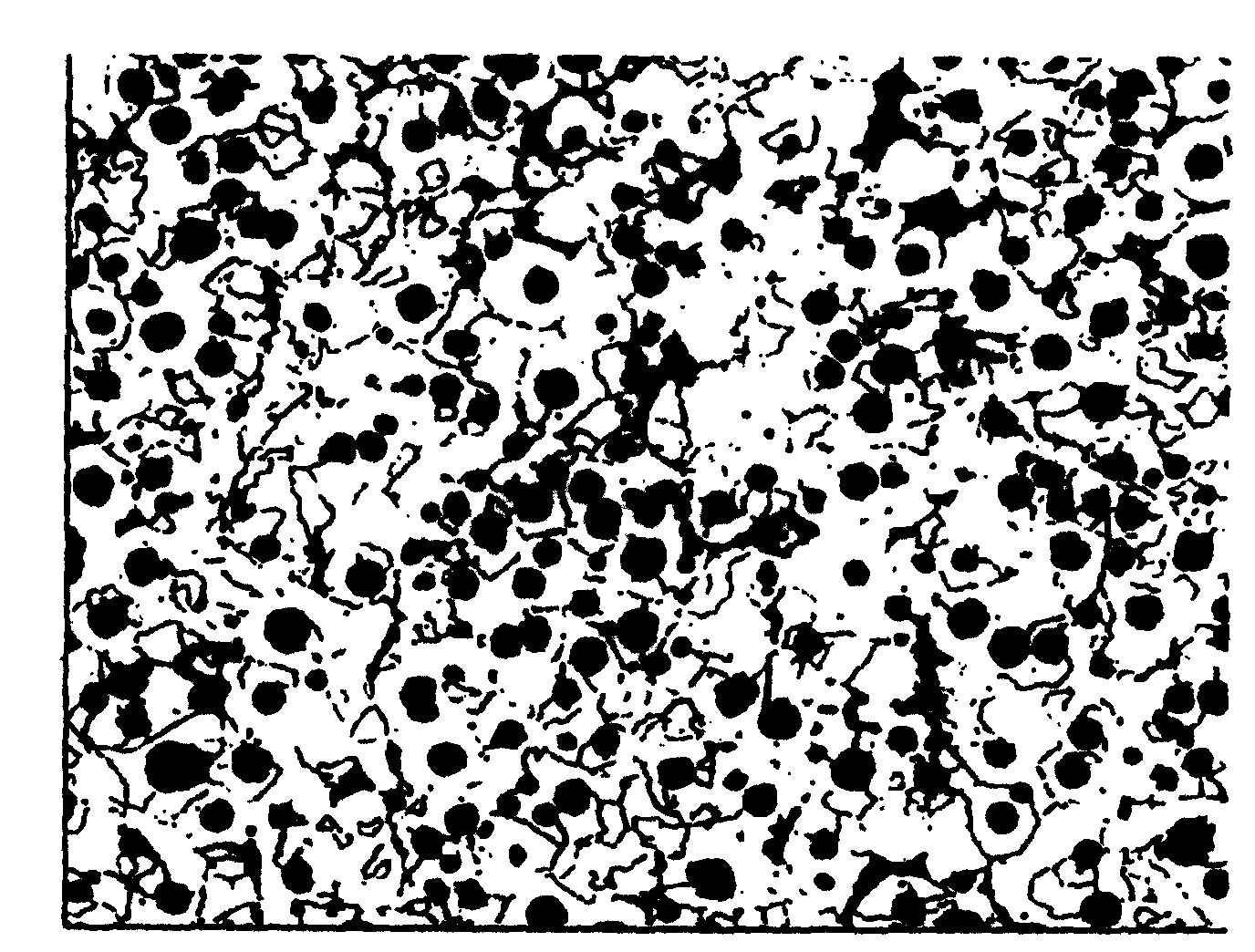

[0011] The inoculum block of the ductile iron mold of the present invention, the main raw material is ferrosilicon, and rare earth and low melting point elements are added at the same time, wherein the weight percentage of each component is: Si accounts for 55-70%; RE accounts for 0.5-5%; low melting point elements 2 to 10%; the rest is iron. Since the main raw material of the commonly used inoculant is ferrosilicon, its melting point is 1310-1330°C, and the pouring temperature of molten iron in industrial production is generally 1330-1380°C, so the high melting point of ferrosilicon is not conducive to the melting of ferrosilicon , thereby affecting the breeding effect. Lowering the melting point of ferrosilicon alloy is an important measure to ensure uniform inoculation. On the basis of ferrosilicon, adding rare earth and low-melting point elements to the inoculant can lower the melting point of the ferrosilicon alloy, which is beneficial to the melting of the inoculant. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com