Tubular, hollow and steel bar reinforced concrete floor member

A technology for reinforced concrete tubular and hollow-core slabs, which is applied to floors, building components, buildings, etc., and can solve problems such as the inability to form two-way reinforced concrete tubular hollow-core slabs with well-shaped ribs, large differences in two-way rigidity, and large thickness of hollow-core slabs. Lightweight, small difference in two-way force transmission, and small deflection deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

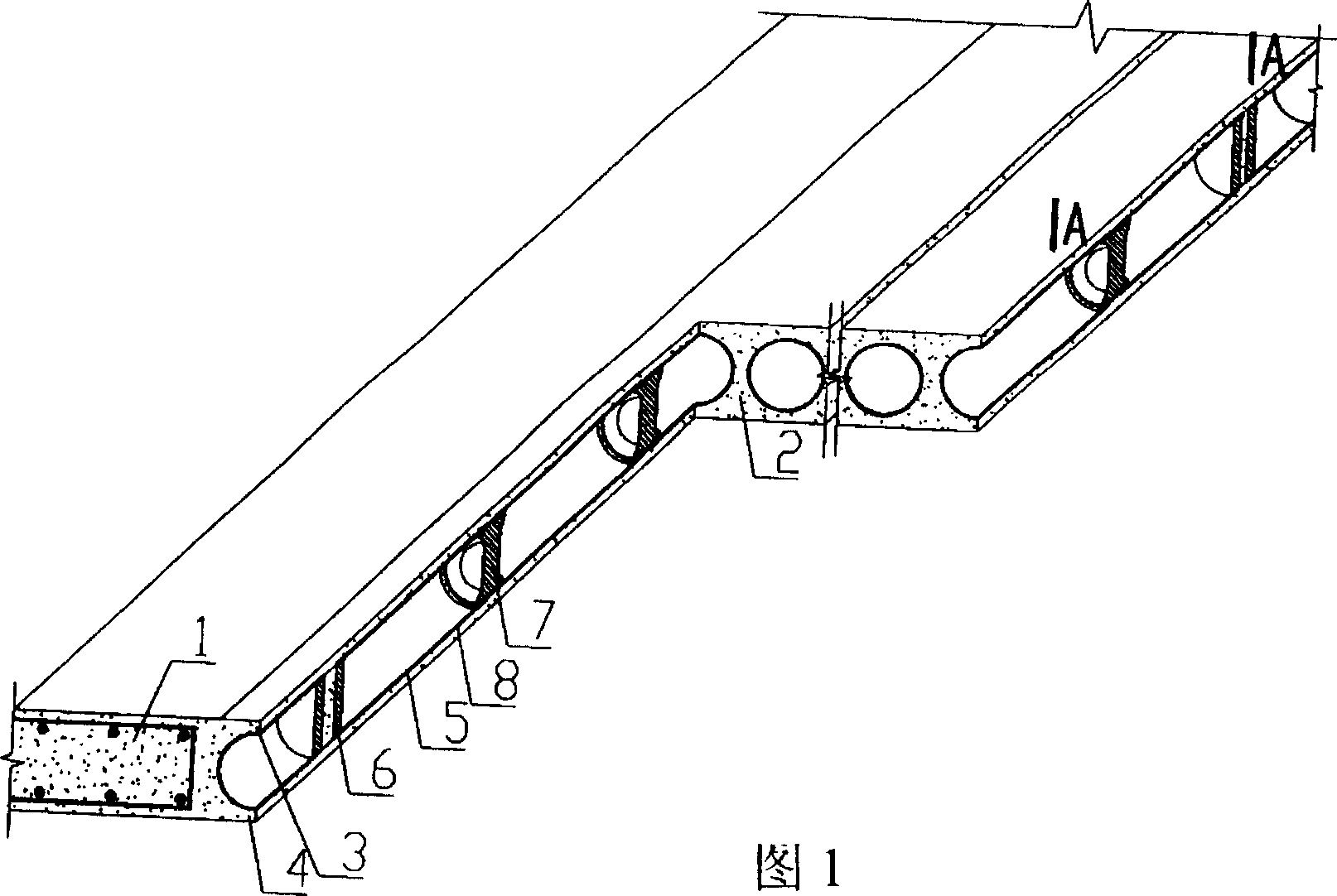

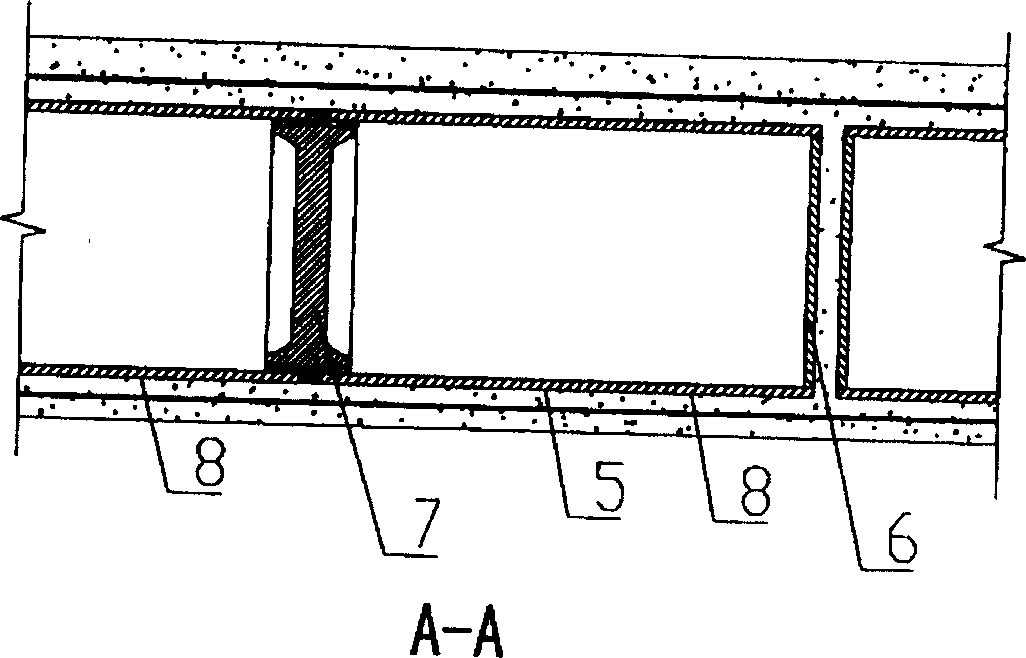

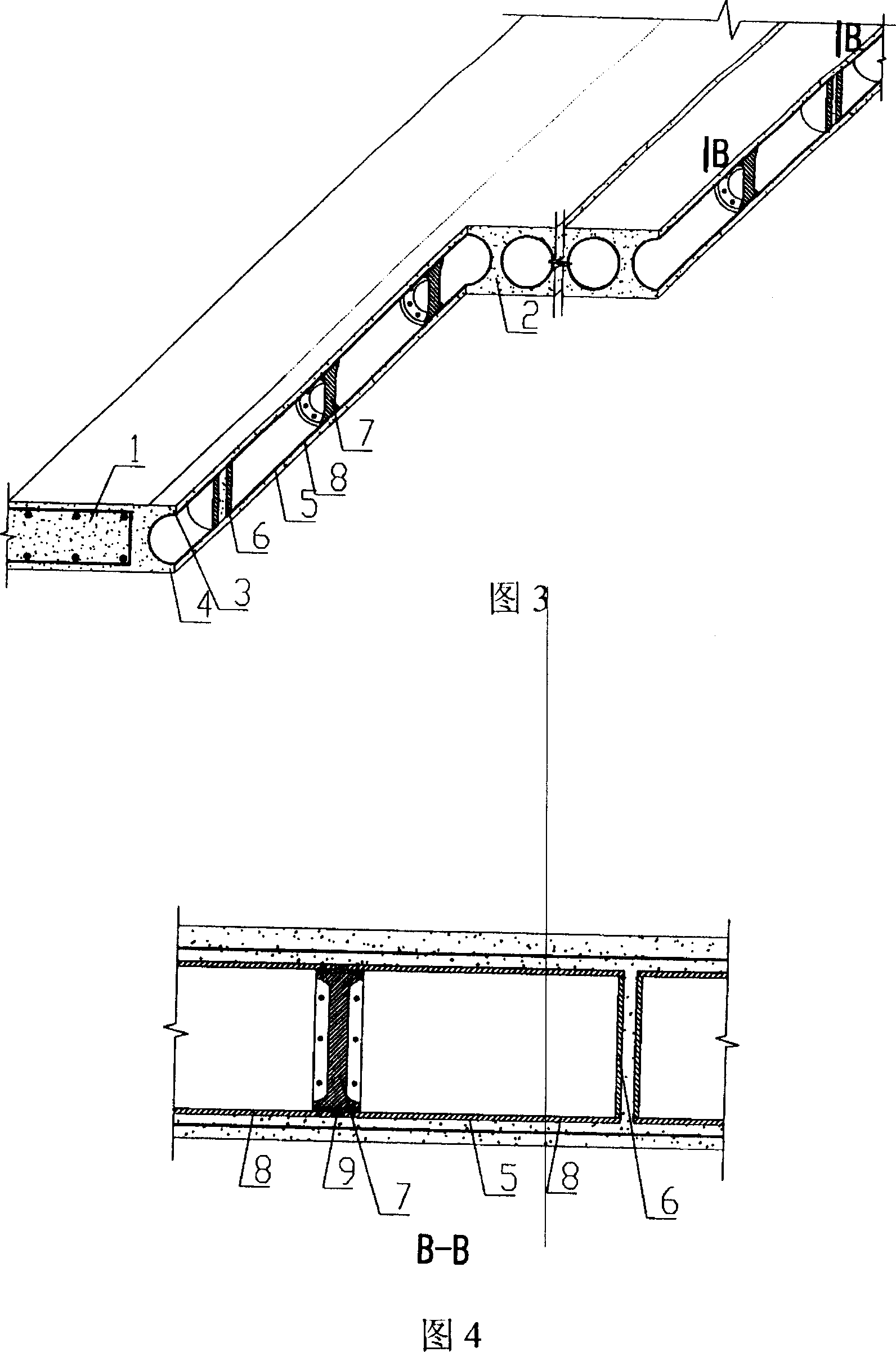

[0071] As shown in the accompanying drawings, the present invention includes beams between wall columns 1, cast-in-place reinforced concrete longitudinal ribs 2, cast-in-place reinforced concrete upper wing plates 3, cast-in-place reinforced concrete lower wing plates 4, hollow tubes 5, and the hollow tubes 5 are arranged alternately Between the cast-in-place reinforced concrete longitudinal ribs 2 or the beams between wall columns 1, above it is the cast-in-place reinforced concrete upper wing 3, below it is the cast-in-situ reinforced concrete lower wing 4, and there are plugs 6 at both ends of the hollow pipe 5 , characterized in that the hollow tube 5 is a combined hollow tube, the combined hollow tube 5 is composed of more than two hollow tube units 8, and the two hollow tube units 8 are butted at the stiffener 7. Fig. 1 shows that the combined hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com