Grooving detection and intelligent sensing processing method and system for semiconductor

A semiconductor and groove detection technology, which is applied in image analysis, image enhancement, instruments, etc., can solve the problems that affect the semiconductor processing effect and processing accuracy, and do not perform groove detection, so as to realize intelligent perception and dynamic correction, ensure quality, Guarantee the effect of processing effect and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

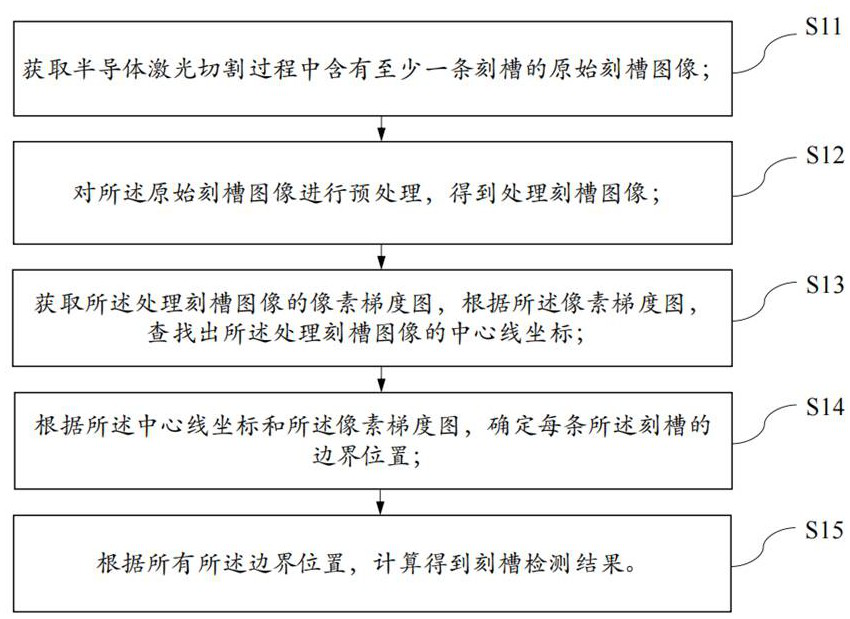

[0100] like figure 1 As shown, a method for detecting grooves in a semiconductor includes:

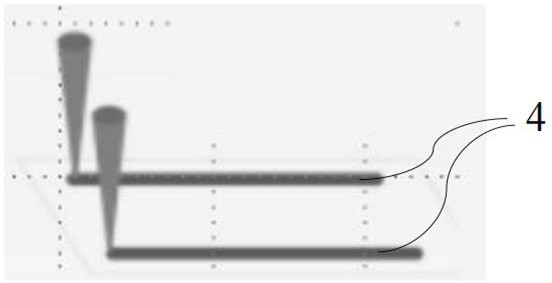

[0101] S11: Acquire an original notch image containing at least one notch during the semiconductor laser cutting process.

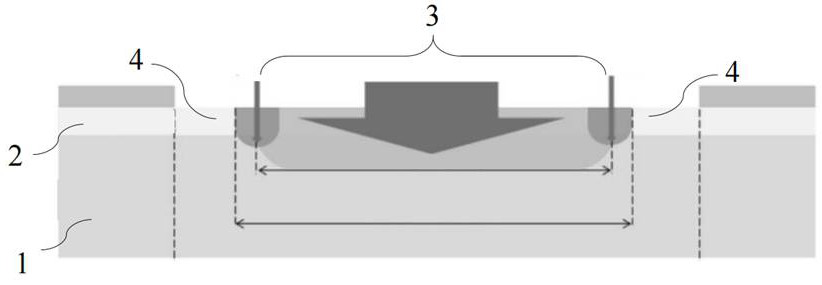

[0102] In the process of semiconductor processing, such as the processing of semiconductor wafers containing Low-k materials in the dielectric layer, it is necessary to use laser grooving technology to shape the light spot into a specific shape through the optical path system, and focus the laser on the surface of the material to achieve a specific groove shape. And use the extremely high peak power of the ultrafast laser to instantly vaporize the Low-k material; there is no intermediate process in this process, which can greatly reduce the heat-affected zone, making the cutting very clean and free of residues.

[0103] In the above-mentioned laser grooving technology, the mainstream method is to first use Dual narrow cutting (ie double thin line cutting) to form...

Embodiment 2

[0205] like Figure 9 As shown, an intellisense processing method for Low-k materials, including:

[0206] S21: Laser cutting the semiconductor using a laser grooving tool;

[0207] S22: According to the groove detection method of Embodiment 1, calculate and obtain the real-time groove detection result in the semiconductor laser cutting process;

[0208] S23: Perform real-time correction on the semiconductor laser cutting process according to the real-time groove detection result to complete intelligent perception processing.

[0209] The intelligent perception processing method of this embodiment can realize real-time deviation correction in the laser processing process, effectively ensure the processing effect and processing accuracy of the semiconductor, and thus ensure high-quality integrated circuit products.

[0210] Preferably, S21 includes:

[0211] S211: using the laser grooving tool to form two narrow grooves in the dicing track of the semiconductor;

[0212] S21...

Embodiment 3

[0216] like Figure 10 As shown, a semiconductor groove inspection system includes:

[0217] The image acquisition module is used to acquire the original groove image containing at least one groove during the semiconductor laser cutting process;

[0218] an image processing module for preprocessing the original grooved image to obtain a processed grooved image;

[0219] a centerline search module, configured to obtain a pixel gradient map of the processed grooved image, and find out the centerline coordinates of the processed grooved image according to the pixel gradient map;

[0220] a boundary determination module, configured to determine the boundary position of each of the grooves according to the centerline coordinates and the pixel gradient map;

[0221] The result calculation module is used for calculating the groove detection result according to all the boundary positions.

[0222]The groove detection system of this embodiment can accurately obtain the groove detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com