Lamp heat dissipation structure and ceiling lamp

A technology of heat dissipation structure and lamps, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problems of low assembly efficiency and complex heat dissipation fin process, so as to improve assembly efficiency and reduce production The effect of simple cost and connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

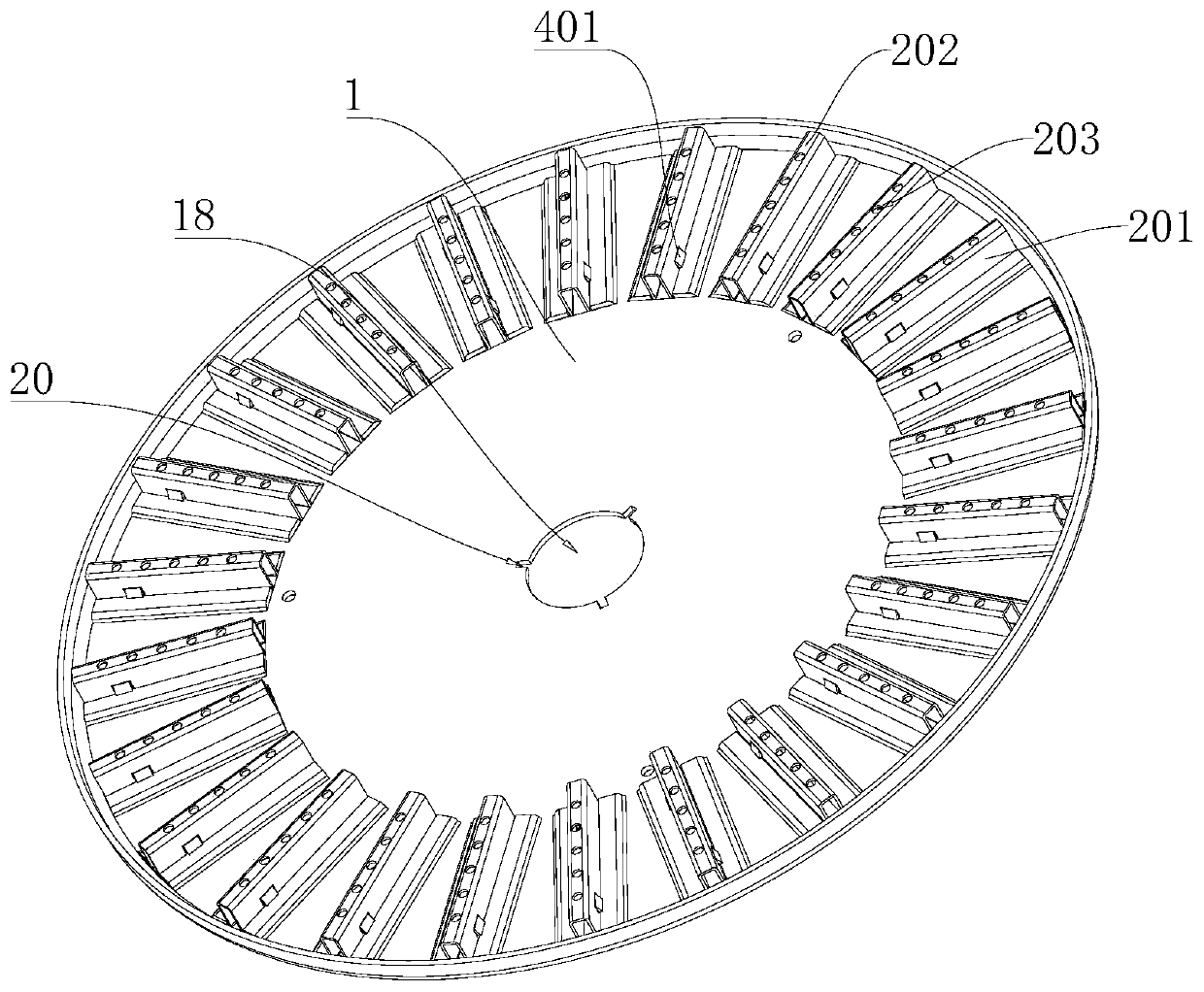

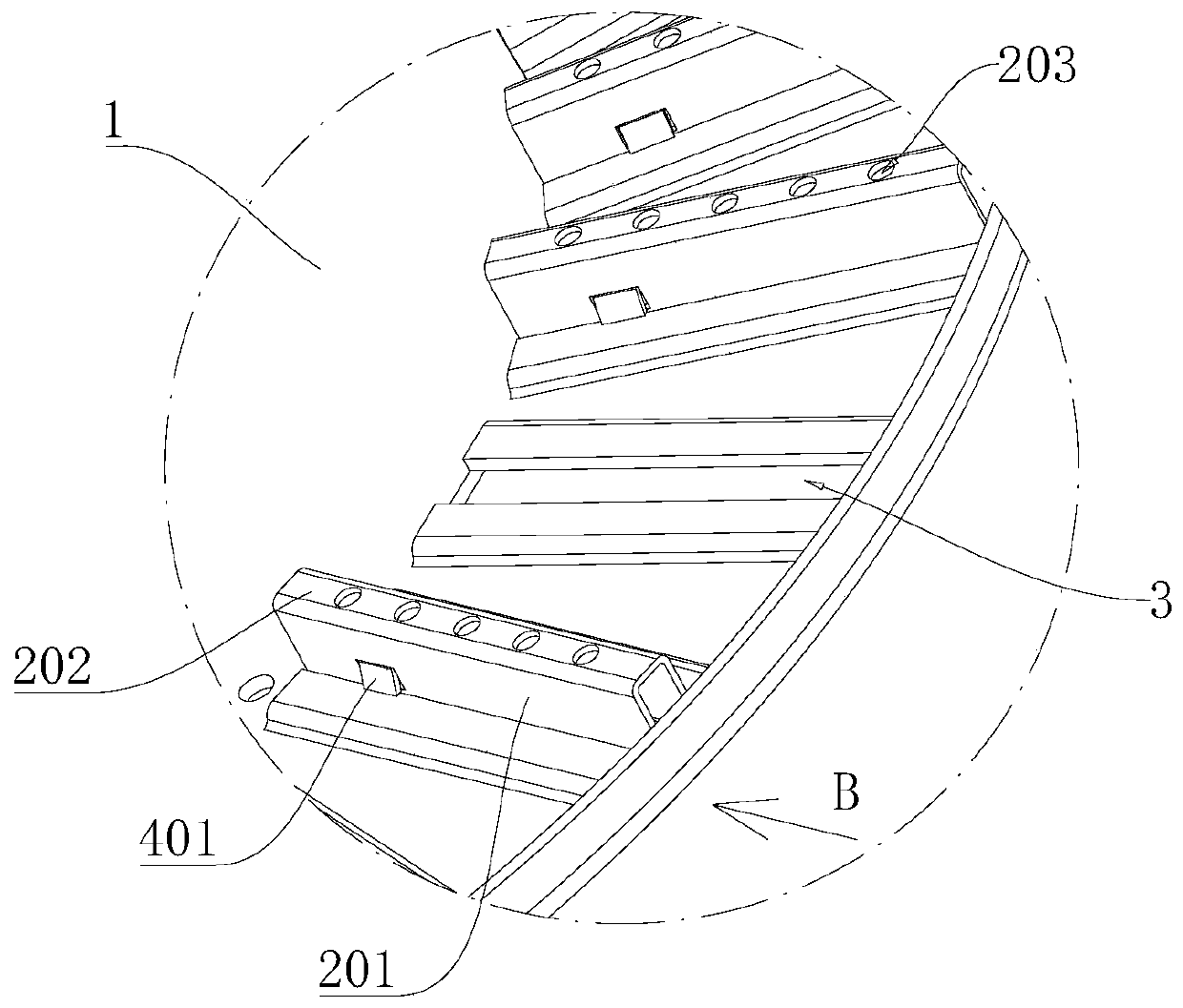

[0049] Please also refer to Figure 1 to Figure 7 , as a specific implementation of the heat dissipation structure of the lamp provided by the present invention, the buckle member 4 includes a buckle 401 and a limiting plate 402. There are multiple buckles 401, and the multiple buckles 401 are respectively located on the sides of the heat dissipation fins 2. On both sides, the limiting plate 402 is arranged at the front end of the cooling fin 2 , and the buckle 401 and the limiting plate 402 are used to clamp the rear shell 1 from the front and rear sides of the bayonet 3 .

[0050] The cooling fins 2 are gradually inserted backward into the bayonet socket 3 from the front side of the rear shell 1, and the cooling fins 2 gradually protrude backward from the bayonet socket 3. During the insertion process, the buckle 401 is compressed and gradually shrinks, so that the cooling fins 2 can Continue to push backward, when inserted in place, the limit plate 402 abuts against the fro...

Embodiment approach

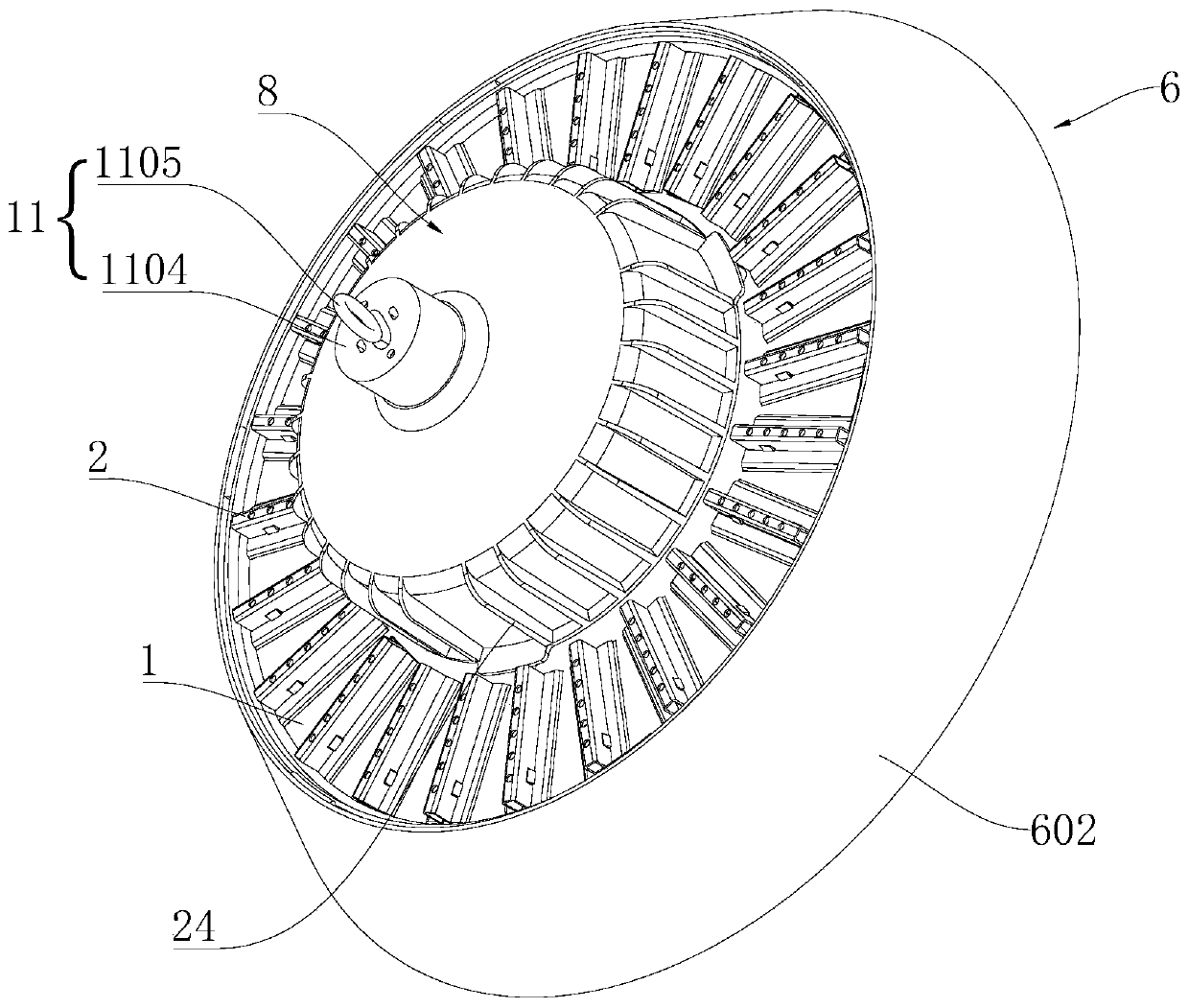

[0078] see figure 1 , Figure 7 , Figure 14 and Figure 15 , as a specific embodiment of the high dome lamp provided by the present invention, the lampshade 6 includes a front cover body 601 and a side cover body 602 arranged on the outer periphery of the front cover body 601, and the side cover body 602 protrudes forward from the front cover body 601 The front end face is integrally arranged with the front cover body 601 , the aforementioned second buckle 17 is arranged in the middle of the front cover body 601 , and the inner diameter of the side cover body 602 gradually decreases from front to back. The lampshade 6 forms a turn-around structure, which not only emits light downwards, but also diffuses light upwards, which can slightly illuminate the ceiling and provide different lighting effects. The integrated structure of the front cover body 601 and the side cover body 602 enables the lampshade 6 to be manufactured through a set of moulds, which simplifies the manufac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com