Brake caliper for disk brake

A disc brake and brake caliper technology, applied in the field of brake calipers, can solve problems such as uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

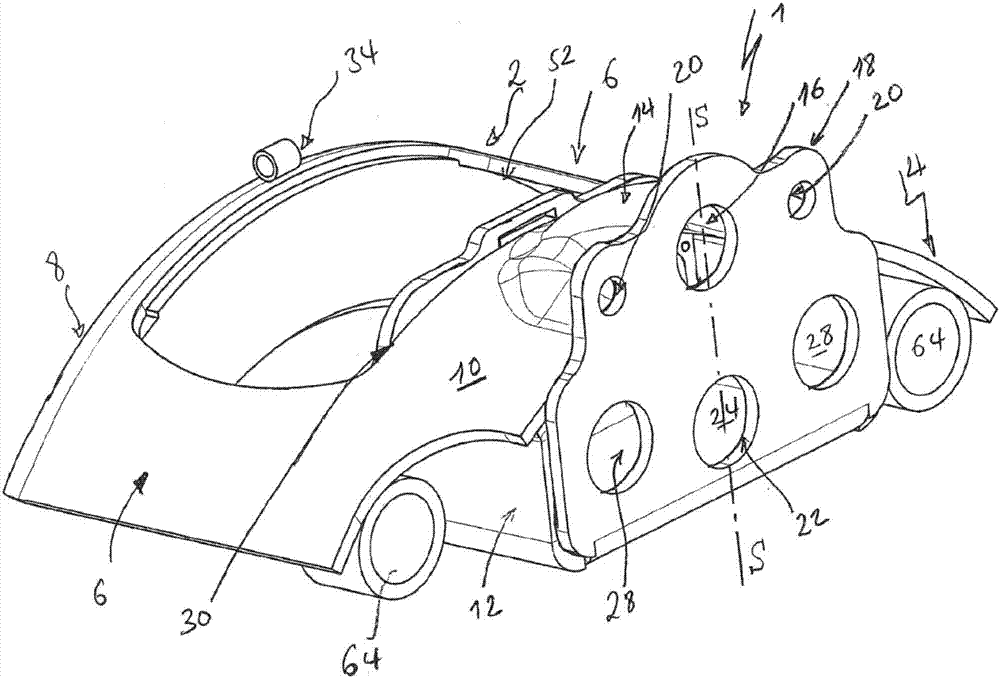

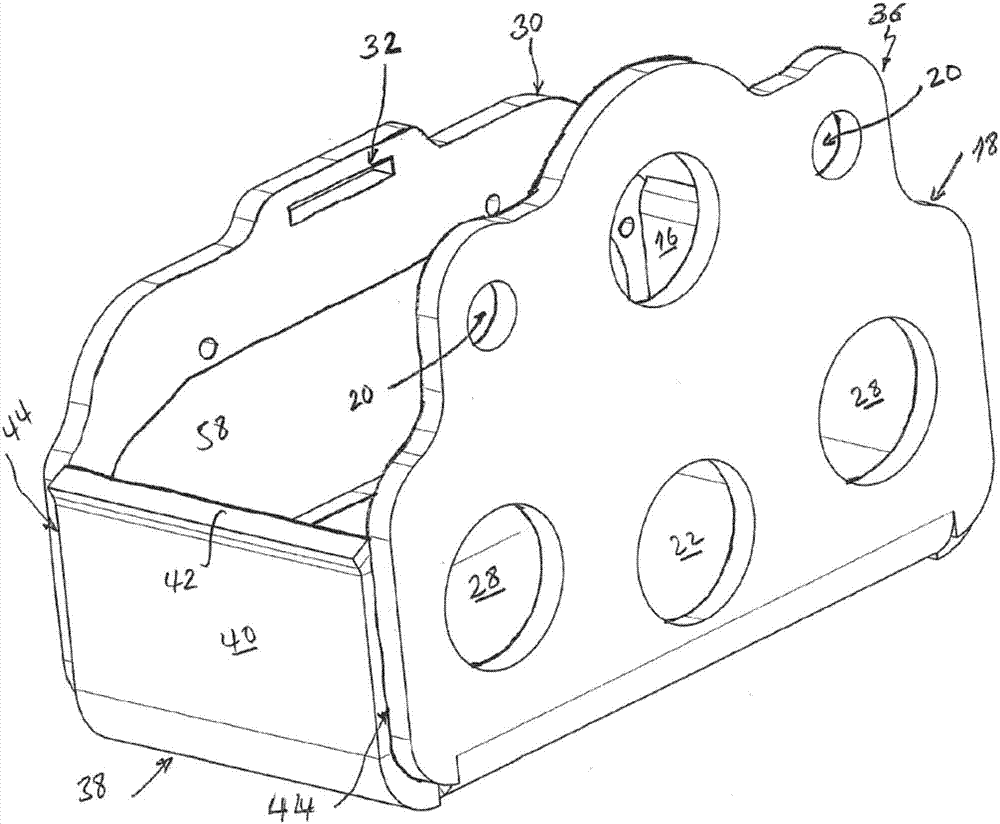

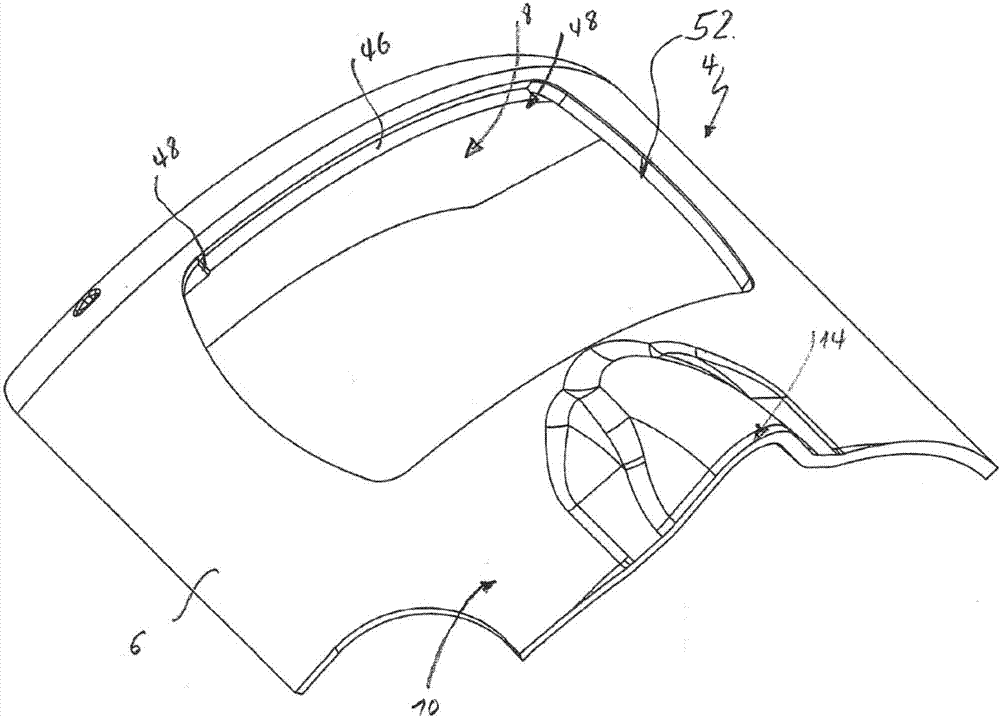

[0036] figure 1 is a perspective view of one embodiment of a brake caliper, the main components of which are described below. This general description applies to all embodiments.

[0037] The brake caliper denoted by the reference symbol 1 has a caliper frame 2 consisting only of sheet metal elements that have been cut or punched, deep-drawn and connected, usually by welding. The tongs frame 2 comprises a cover section 4 which is constructed as a one-piece sheet metal element and forms a tensioning rod 6 and a tongs back 8 connecting the two tensioning rods 6 together. The tie rod 6 is detached from a cover 10 formed by the cover section 4 , which delimits on the top side and covers a housing 12 , which will be described further below. Such as figure 1As shown, this housing 12 is mirror-symmetrical about an axis of symmetry denoted by reference symbol S. The cover 10 has an upper cover dome 14 which covers a central upper bore 16 which is opened in the outer section 18 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com