Double-fiber grating diaphragm type pressure sensor and low-pressure calibration system and method thereof

A dual-fiber grating and pressure sensor technology, which is applied in the measurement of fluid pressure, the measurement of the change force of the optical properties of the material when it is stressed, and instruments, can solve the problems of difficult disassembly, low extraction accuracy, and complex structure. , to achieve the effect of convenient construction, high calibration accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

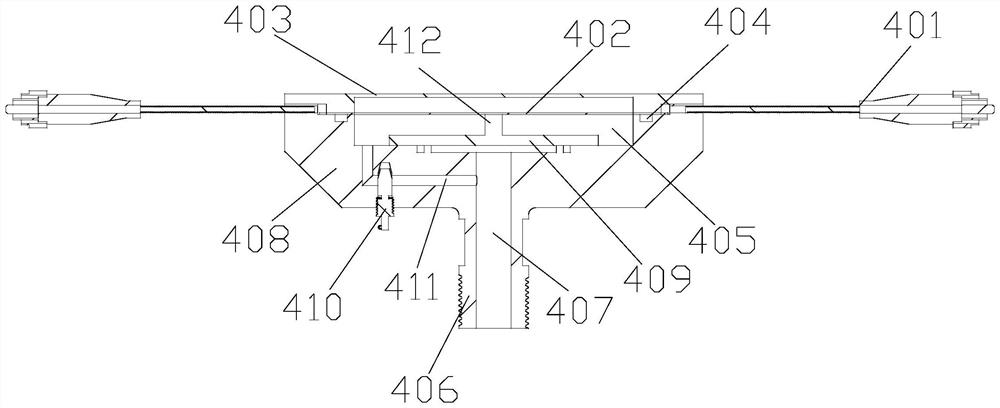

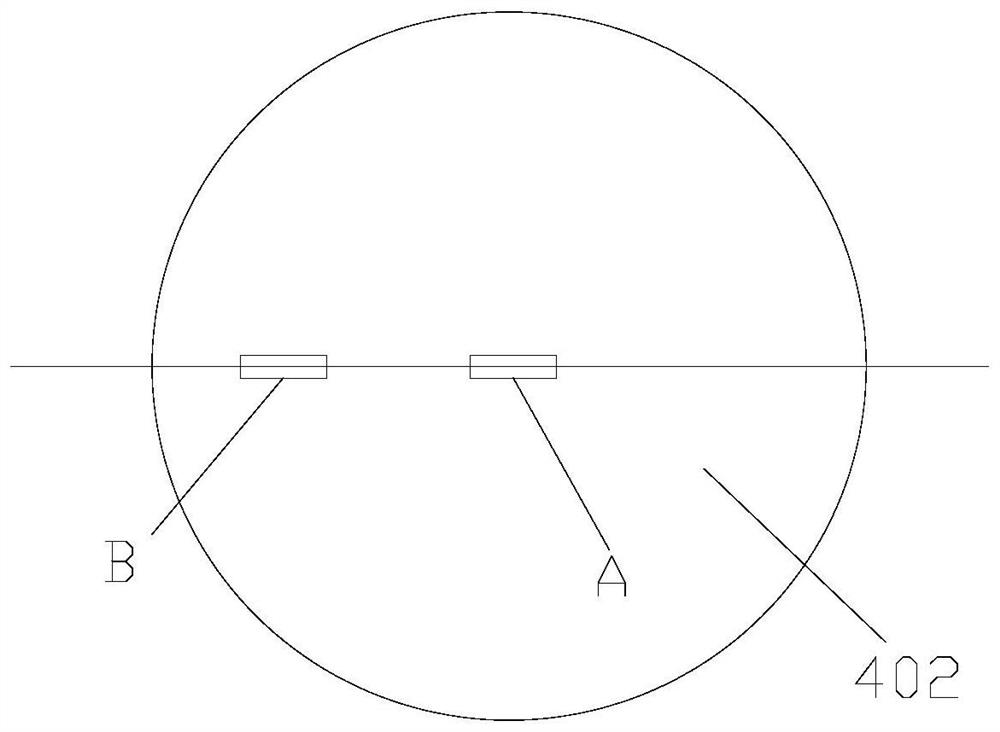

[0046] Embodiment 1 provides a double fiber grating diaphragm pressure sensor, such as figure 1 As shown, the double fiber grating diaphragm pressure sensor 4 includes a base 408 and a pressure measuring grating assembly mounted on the base 408. The base 408 has a conical structure, and the base 408 is provided with an open type Cavity 405, the cavity 405 is a cylindrical cavity arranged in the middle of the base 408, its cavity opening is opened on the bottom surface of the base 408, and a sealing groove 404 and a low-pressure diaphragm installation groove are arranged at the cavity opening, A sealing ring is placed in the groove 404, a medium introduction joint 406 is arranged in the middle of the top surface of the base 408, a pressure introduction hole 407 communicated with the cavity 405 is arranged in the medium introduction joint 406, and a pressure introduction hole 407 is arranged on the side of the pressure introduction hole 407. To the exchange hole 411 of the cavit...

Embodiment 2

[0050] Embodiment 2 provides a low-voltage calibration system for a double fiber grating diaphragm pressure sensor, such as Figure 5 and Image 6 As mentioned above, the low-voltage calibration system includes a pressure signal demodulation module 1, an optical fiber jumper 2, a liquid level measuring device 5, a water tank 11 and one or two or more double fiber grating diaphragm pressure sensors 4, one Or two or more double fiber grating diaphragm pressure sensors 4 are connected in series with each other through the FC / APC joint 401, and then connected with the signal input end of the pressure signal demodulation module 1 through the fiber jumper 2; The modulation module 1 includes a PC terminal 101 and a fiber grating demodulator 102, one or two or more double fiber grating diaphragm pressure sensors 4 form distributed multi-point measurement and long-distance connection demodulation through fiber jumpers 2 instrument 102; the fiber grating demodulator 102 is used to coll...

Embodiment 3

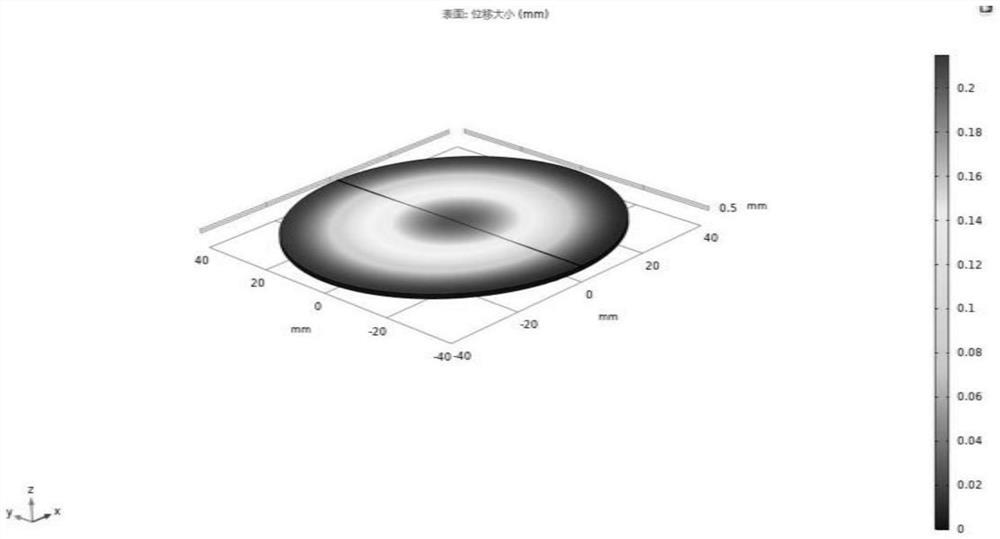

[0052] Example 3: Use the calibration system in Example 2 to perform low pressure calibration on the double fiber grating diaphragm pressure sensor 4 in Example 1, wherein the low pressure diaphragm 402 of the double fiber grating diaphragm pressure sensor 4 is made of 316 stainless steel, The radius is 50mm, the thickness is 0.5mm; the high-pressure diaphragm 409 is made of 316 stainless steel, the radius is 50mm, and the thickness is 2mm; the liquid level measuring device 5 in the calibration system has an outer diameter of 28mm, an inner diameter of 20mm, a length of 2000mm, and the threaded interface is M20* 1.5 internal thread, material is acrylic pipe; straight-through valve 3 is Q91SA imitation American straight-through panel valve, material is 316 stainless steel; liquid level fine-tuning valve 6 is ZA-YBS-series, fine-tuning accuracy is 0.1mm; water injection pipe 7 is 535FT single The control valve 8 is ZC-400 valve, the material is 304 stainless steel, and the motor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com