Control method for self-adaptively adjusting braking force of hydraulic braking road roller

A self-adaptive adjustment and hydraulic braking technology, applied in the direction of the brake, can solve problems such as uneven road compaction, layer shifting, and large inertial loads, so as to avoid uneven road compaction, take into account the safe anti-collision distance, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

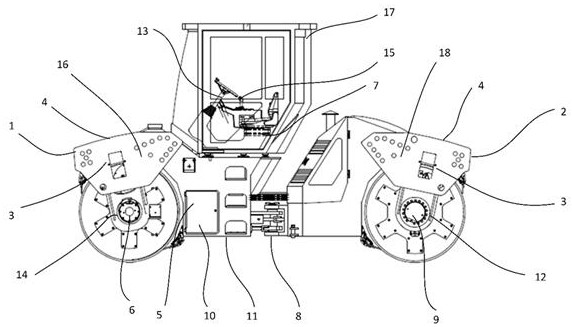

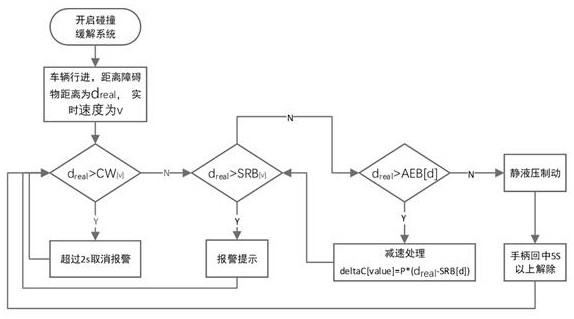

[0053] Hereinafter, the present invention will be further described with reference to the accompanying drawings by taking a hydraulically braked twin-drum road roller as an example.

[0054] like figure 1 As shown, the double-drum road roller includes a first vehicle body 16 and a second vehicle body 18 that are hingedly connected at the front and rear, the cab 17 is arranged on the first vehicle body 16, and the hydraulic braking part of the double-drum road roller includes a drive proportional pump 11 , a drum drive proportional motor for driving the drum and a handle 15 for controlling the gear; the double drum roller also includes an obstacle detection part, a compactness detection part, a vehicle speed detection part and a braking force analysis part installed on the body Control section.

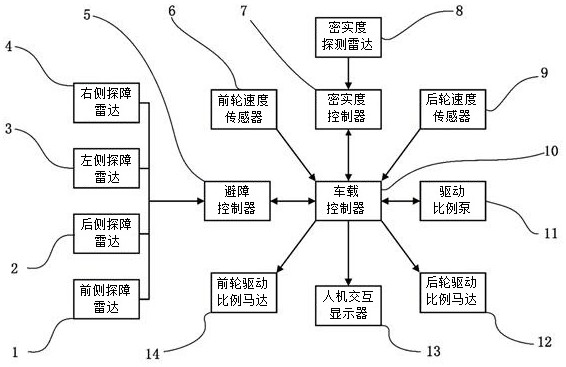

[0055] like figure 2 As shown, the obstacle detection part includes an obstacle detection radar, and the obstacle detection radar includes at least a front obstacle detection radar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com