Manufacturing method of glass breaking ball with convex structure on base body based on heat source cladding method

A manufacturing method and substrate technology, which can be used in additive manufacturing, glass production, coating, etc., can solve the problems of inability to complete remote and high-altitude glass breaking, complicated manufacturing processes, and complex processes, so as to shorten the throwing distance and facilitate rapid glass breaking. , The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

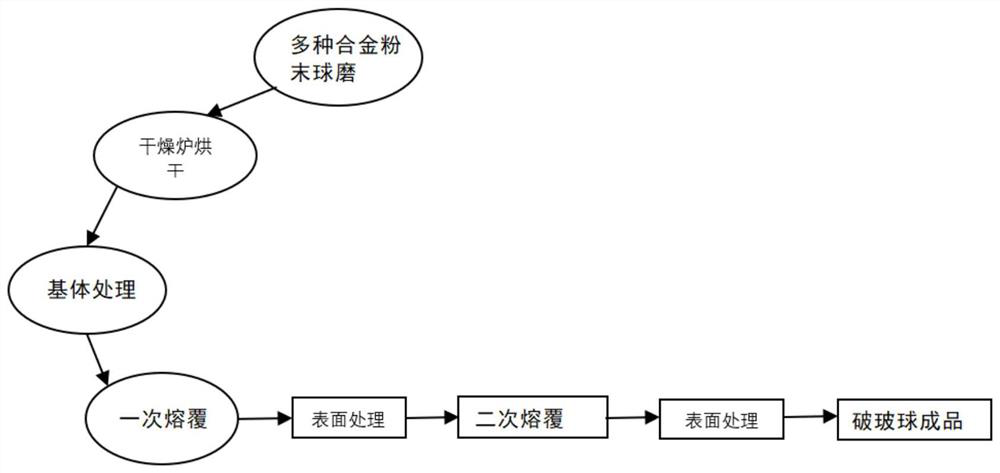

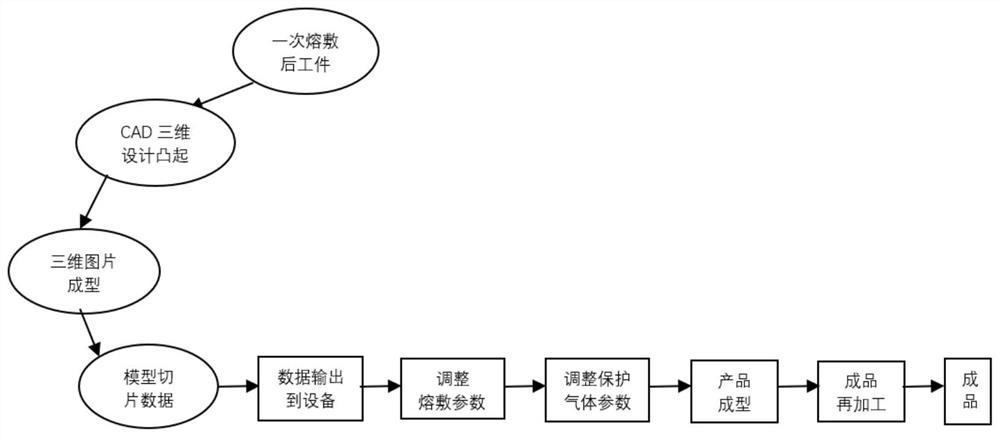

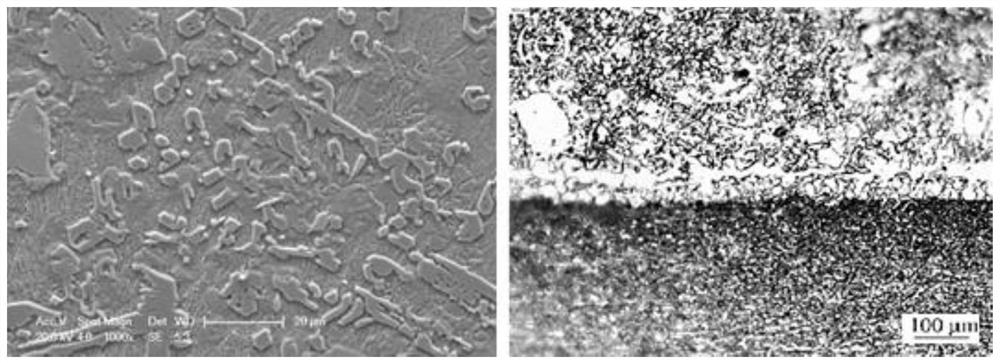

[0035]The H13 steel ball is used as the matrix, and Ni60+WC alloy bumps are clad on its surface by plasma cladding. The specific method is as follows: ① Use WC powder with a purity higher than 99.9% and Ni60 powder as raw materials, and the powder particle size At 48-75μm, add 40% mass fraction of WC powder to Ni60 powder and mix it evenly, put it in a ball mill and grind for 3 hours; ② Dry the powder in a drying oven for 1.5 hours, and the drying temperature is 130 ℃; ③ For The surface of the substrate is cleaned, degreasing and rust removed, and then the substrate is placed in a drying furnace and kept at 80°C; ④ L5-400PC high-energy plasma arc powder surfacing equipment is used to carry out the cladding operation on the H13 steel substrate, and the surfacing current It is 180A, and a transition layer with an alloy layer thickness of about 1-3mm is obtained after cladding. ⑤Secondary cladding is performed on the surface of the transition layer, and the height of each hard pr...

Embodiment 2

[0038] Taking Q235 steel ball as the matrix, laser cladding is used to clad WC / (Al, Co, Cr, Fe, Ni, Nb high-entropy alloy) bumps on its surface. The specific method is as follows: ① The purity is higher than 99.5%, six kinds of high-entropy alloy powders Al, Co, Cr, Fe, Ni and Nb are prepared in the atomic ratio of 1:1:1:1:1:1; WC powder is added in the form of mass fraction of 25%. The high-entropy alloy Al, Co, Cr, Fe, Ni, Nb0.75 powders were put into a ball mill for grinding for 2.5 hours; ② the powders were dried in a drying furnace for 1.5 hours, and the drying temperature was 135 °C; ③ for the substrate The surface is cleaned, degreasing and rust removed, and then the substrate is placed in a drying furnace and kept at 85°C; ④ LDF4000-100 semiconductor laser is used to perform cladding operation on the 304 stainless steel substrate. The process parameters are: laser power 1100W, scanning The speed was 8 mm / s, the spot diameter was 4 mm, and the defocus amount was 22 mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com