Kitchen waste oil extraction treatment process method and system

A technology of kitchen waste and process method, applied in chemical instruments and methods, biological organic part treatment, transportation and packaging, etc., can solve problems such as incomplete oil extraction, oil accumulation in anaerobic fermentation system, and unstable process operation. , to achieve the effect of improving the speed of preprocessing and improving the efficiency of comprehensive extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

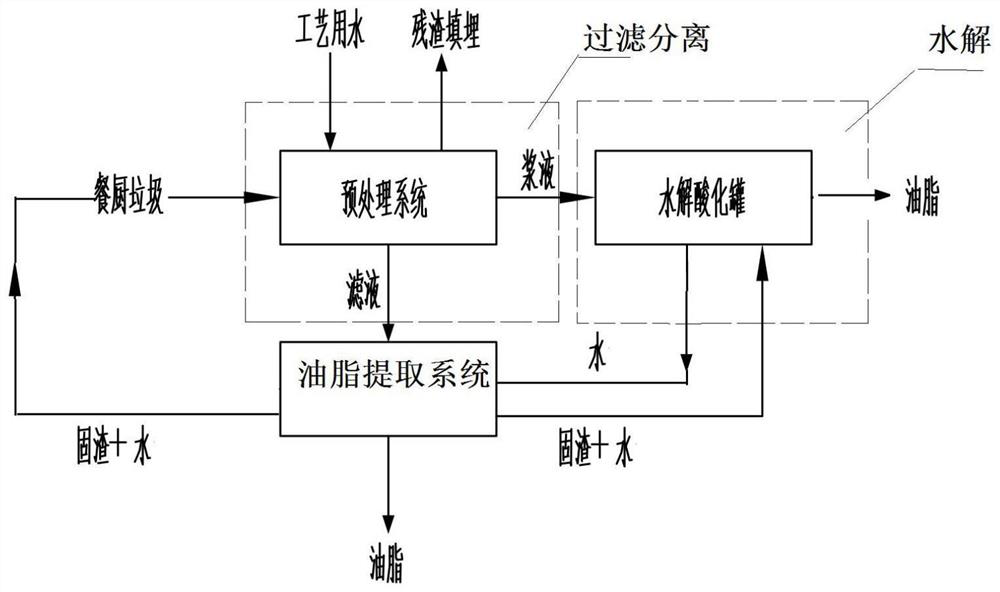

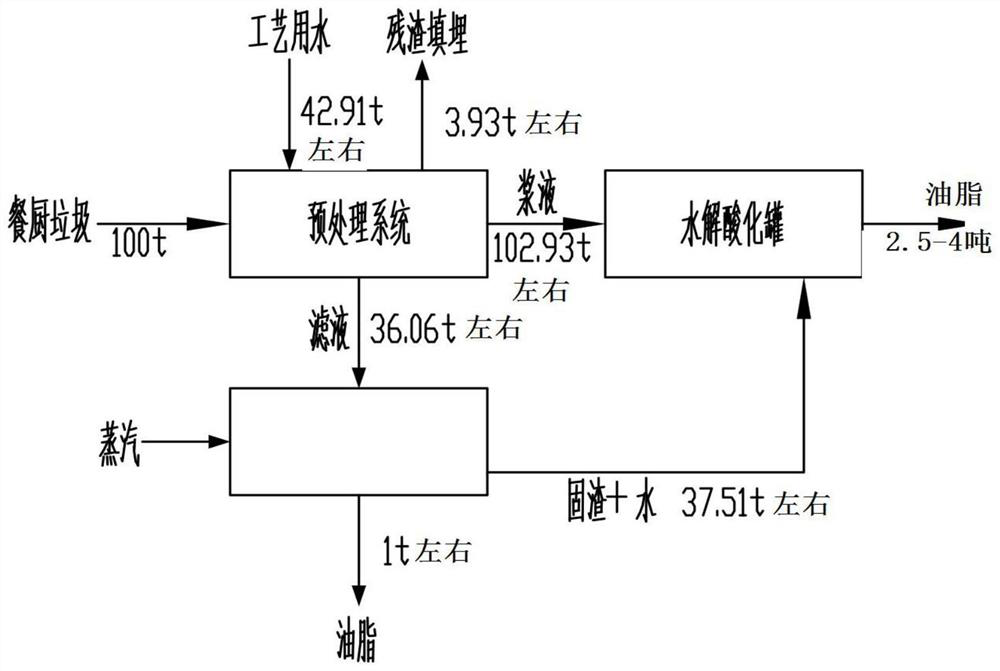

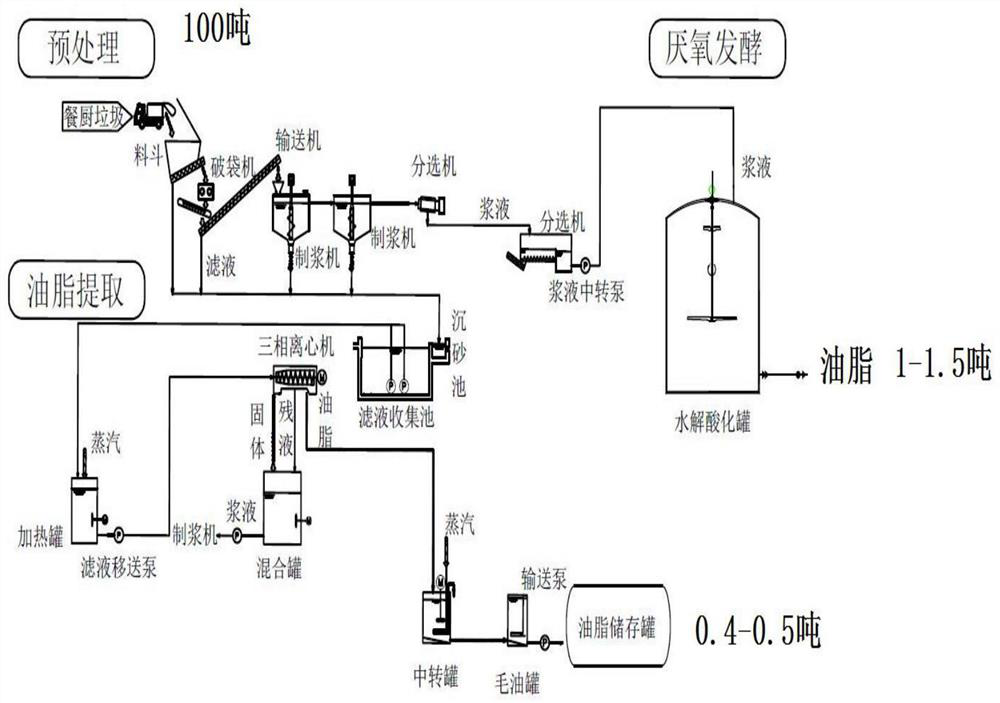

[0042] An oil extraction treatment process method for kitchen waste treatment comprises the following steps: filtration, separation, and hydrolysis;

[0043] In the filtration and separation step, in the pretreatment system (preferably, the pretreatment of kitchen waste includes crushing, sorting (separating large pieces of metal), etc., generally conventional treatment), rinse with water and filter, The solid slag that cannot be washed out by water can be directly landfilled. Preferably, the water pressure of the water washing is 0.01-2 standard atmospheres. When in use, the water is generally washed directly to the kitchen waste, and the filtrate and the filtrate are formed by filtration. Slurry, the filtrate passes through the smaller filter hole, the slurry passes through the larger filter hole, and the slag that cannot pass through the larger filter hole is the slag, which can be directly used for landfill, the filtrate enters the oil extraction system to extract oil, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com