Self-adaptive regulation and control method for flotation dosing

An adaptive control and flotation technology, applied in flotation, reasoning methods, neural learning methods, etc., can solve the problems of long implementation time, lack of accuracy, production index verification, etc., to ensure stability and accuracy, realize Stability, the effect of reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

[0045]In view of the problems that may occur in the flotation process in the beneficiation process in the mine beneficiation production, due to the excessive changes in the iron ore flotation site conditions, the production state cannot be fully monitored and the adjustment is not timely, this embodiment provides a Adaptive control method for flotation dosing; it should be noted that the method in this embodiment may be implemented by an electronic device, and the electronic device may be a terminal or a server.

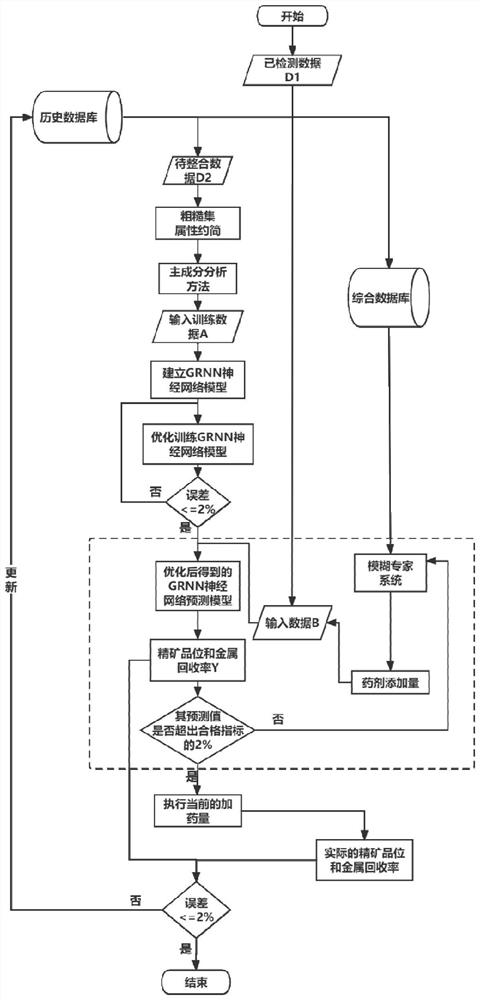

[0046] like figure 1 As shown, a flotation dosing self-adaptive control method includes a sensor detection device, an image acquisition device, electronic equipment and a computer control system, and is characterized in that it incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com