Metal gas diffusion layer and manufacturing method and application thereof

A technology of gas diffusion layer and manufacturing method, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of unimproved drainage and air permeability, complicated processing method and large surface contact resistance, etc. , to achieve the effect of being suitable for large-scale production, the process is simple and easy to operate, and the adhesion is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

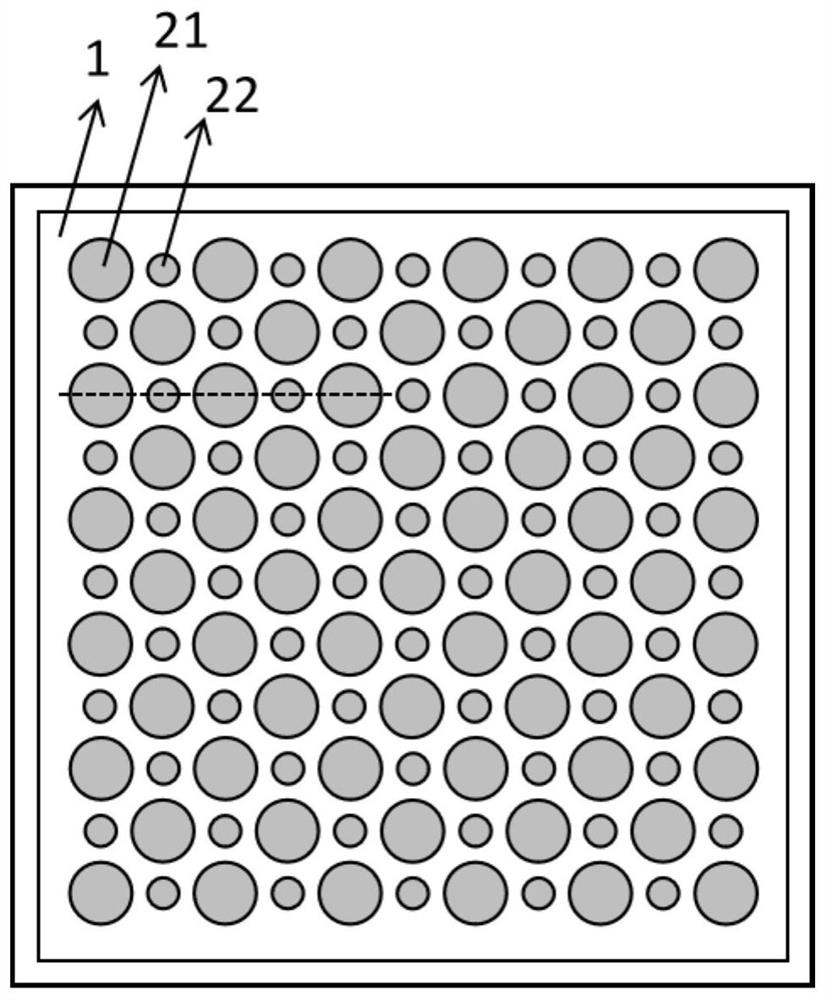

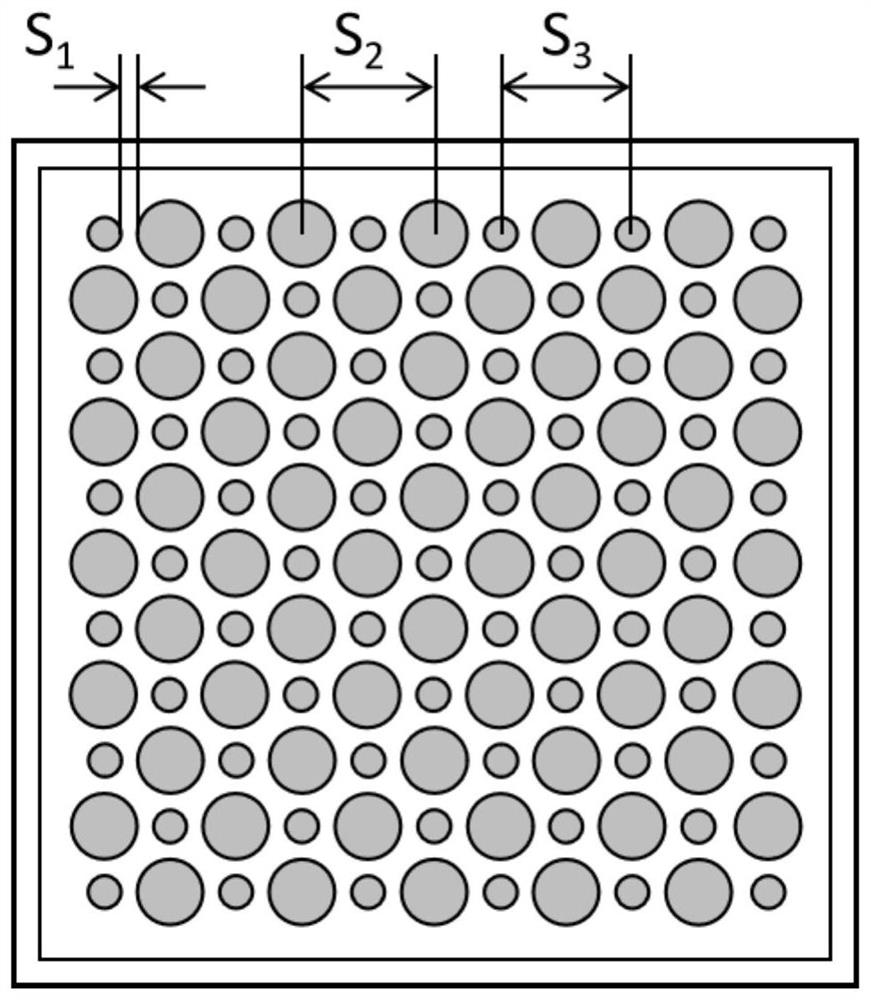

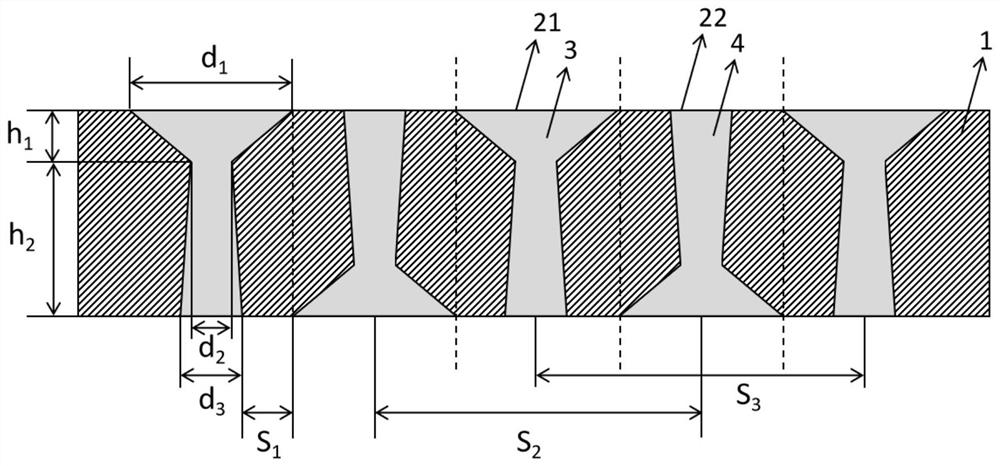

[0044] This embodiment provides a metal gas diffusion layer, the top view of the two sides of the layer is as follows figure 1 and figure 2 shown, figure 1 The schematic diagram of the cross section along the dotted line is as follows image 3 As shown in the figure, the metal gas diffusion layer 1 is made of titanium metal, and its length is 30 mm, the width is 30 mm, and the thickness is 400 μm; in the metal gas diffusion layer 1, there are orderly funnel-like distributions in the positive and negative directions. Through holes, the metal gas diffusion layer 1 forms the inner wall part and the openings A21 and B22 on both sides; the shape of the funnel-like through holes is divided into a head 3 and a skirt 4; the head The central axis of the part 3 and the skirt part 4 are the same straight line and perpendicular to the two side surfaces of the metal gas diffusion layer 1; 70%;

[0045] The head 3 is a circular frustum, and the head 3 forms a diameter d on the surface ...

Embodiment 2

[0049] This embodiment provides a metal gas diffusion layer, the top view of the two sides of the layer is as follows Figure 4 and Figure 5 As shown in the figure, the material of the metal gas diffusion layer 1 is copper alloy, its length is 35mm, the width is 25mm, and the thickness is 300μm; Through holes, the metal gas diffusion layer 1 forms the inner wall part and the openings A21 and B22 on both sides; the shape of the funnel-like through holes is divided into a head and a skirt; the head and The central axis of the skirt is the same straight line and is perpendicular to both sides of the metal gas diffusion layer; the total area of the inner walls of all the through holes accounts for 80% of the total area of the inner and outer surfaces of the metal gas diffusion layer;

[0050] The head is a regular quadrangular pyramid, and the head forms a square opening A21 on the surface of the metal gas diffusion layer, and the diameter of the inscribed circle of the open...

Embodiment 3

[0054] This embodiment provides a metal gas diffusion layer, the top view of the two sides of the layer is as follows Image 6 and Figure 7 As shown, the material of the metal gas diffusion layer 1 is stainless steel, its length is 60mm, the width is 50mm, and the thickness is 600μm; The metal gas diffusion layer 1 forms the inner wall part and the openings A21 and B22 on both sides; the shape of the funnel-like through hole is divided into a head and a skirt; the head and the skirt The central axis of the part is the same straight line and perpendicular to both sides of the metal gas diffusion layer; the total area of the inner walls of all the through holes accounts for 75% of the total area of the inner and outer surfaces of the metal gas diffusion layer;

[0055] The head is a regular triangular prism, and the head forms an equilateral triangle (equilateral triangle) opening A21 on the surface of the metal gas diffusion layer, and the diameter of the inscribed circle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com