Carbon fiber paper as well as preparation method and application thereof

A carbon fiber paper and chopped fiber technology, applied in the directions of fiber processing, fiber type, fiber chemical characteristics, etc., can solve the problems of uniformity, poor flatness, poor tensile strength of carbon paper, and difficulty in dispersion of the forming base paper, and achieves the realization of batch production. The effect of large-scale production, simple process flow and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a preparation method of carbon fiber paper, comprising the following steps:

[0029] 1) preparing acrylonitrile-N-vinylformamide copolymer by a dry-spraying wet method to prepare polyacrylonitrile-based pre-filaments, and obtaining polyacrylonitrile-based chopped fiber pre-filaments through chopped treatment;

[0030] 2) The polyacrylonitrile-based chopped fiber precursors are sequentially subjected to forward and reverse spunlace, drying and winding to obtain a polyacrylonitrile-based non-woven felt;

[0031] 3) pre-oxidizing the polyacrylonitrile-based non-woven felt to obtain a polyacrylonitrile-based pre-oxidizing felt;

[0032] 4) After dipping the polyacrylonitrile-based pre-oxidized felt in the resin solution, drying, hot pressing and curing, carbonization and graphitization are performed in sequence to obtain carbon fiber paper.

[0033] In the invention, acrylonitrile-N-vinylformamide copolymer is used as raw material to prepare a spinni...

Embodiment 1

[0056] Using acrylonitrile-N-vinylformamide copolymer as a raw material and dissolving it in dimethyl sulfoxide, a spinning precursor solution with an acrylonitrile-N-vinylformamide copolymer content of 23 wt% was prepared. The spinning precursor solution is finely denier (diameter 5-10um) and highly oriented (orientation degree 93) through dry spray wet spinning, multi-stage water washing and drawing, oil drying, two-stage steam drawing, and heat setting. %) of polyacrylonitrile-based carbon fiber precursors, which were chopped to obtain polyacrylonitrile-based chopped fiber precursors (10 mm in length).

[0057] The polyacrylonitrile-based chopped fiber strands were placed on the carding machine, spunlace in the forward and reverse directions, dried and wound at 70 ° C for 3 hours, and the gram weight was 160 g / m. 2 of polyacrylonitrile-based non-woven felt.

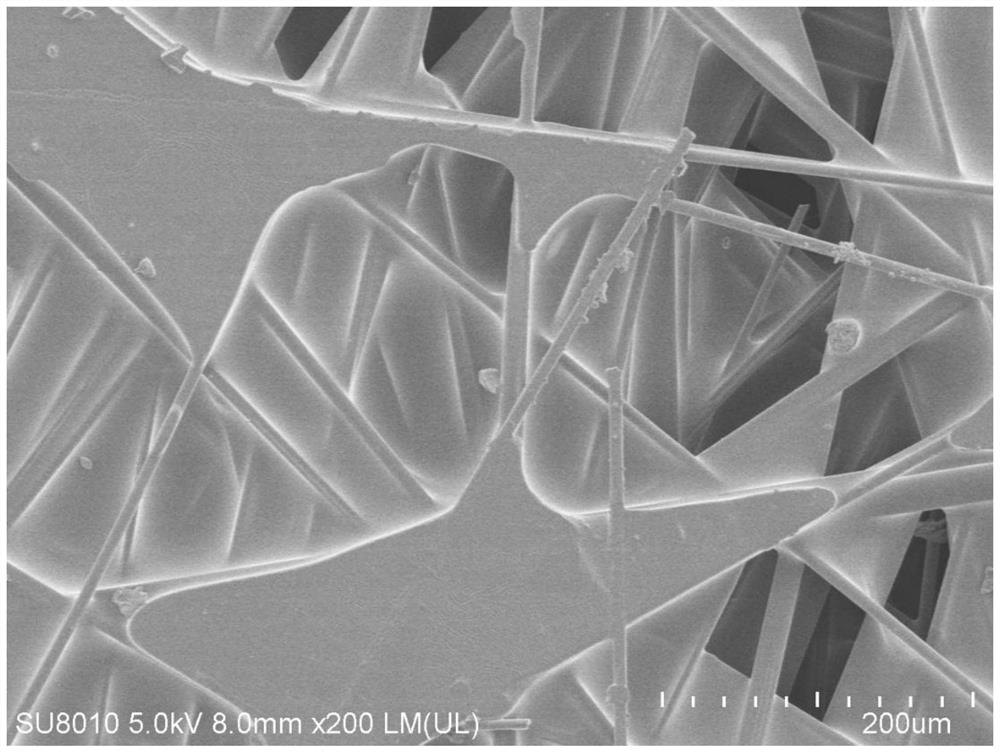

[0058] The polyacrylonitrile-based non-woven felt was put into a multi-stage step-by-step programmed temperature-co...

Embodiment 2

[0063] In Example 1, the mass fraction of cardanol-boron phenolic resin in the solution was changed from 15% to 10%, and other conditions were the same as those in Example 1.

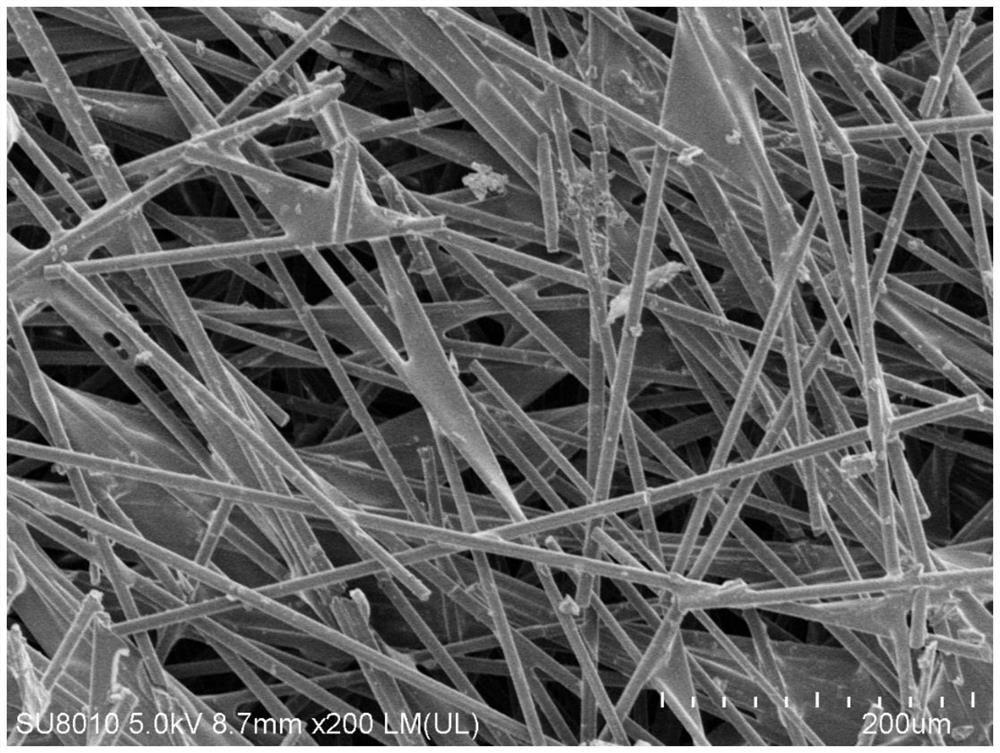

[0064] The scanning electron microscope image of the polyacrylonitrile-based pre-oxidized felt after hot-press curing of the present embodiment is as follows figure 2 shown, by figure 2 It can be seen that the polyacrylonitrile-based pre-oxidized felt after hot pressing and curing is composed of staggered fiber webs, and the fibers are connected by cured resin.

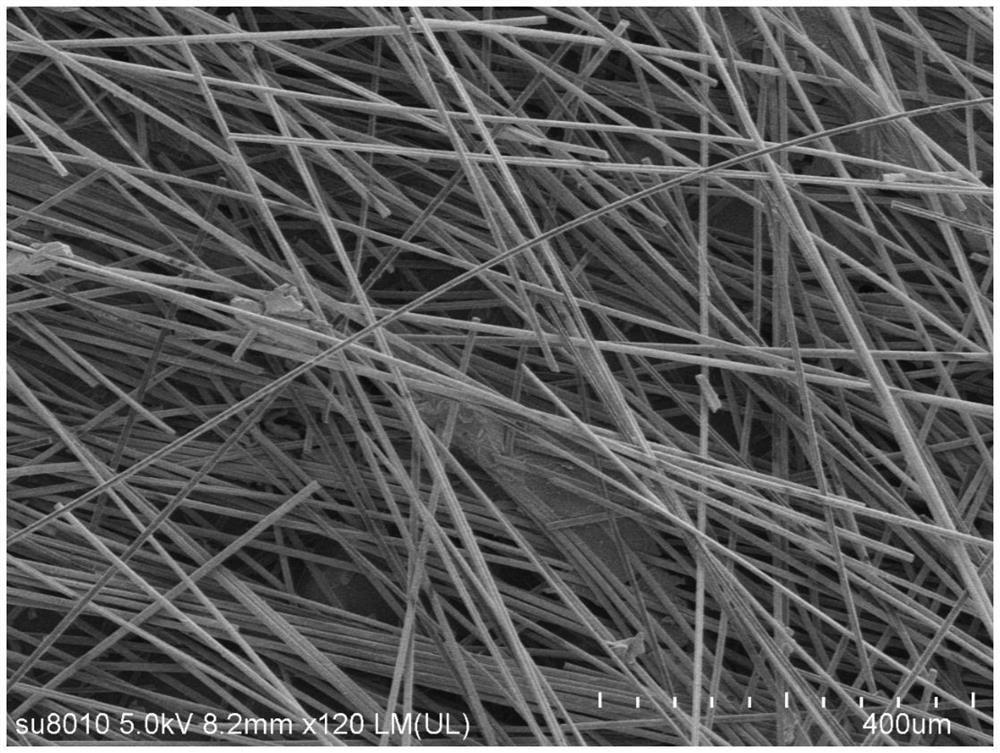

[0065] The scanning electron microscope image of the carbon fiber paper of the present embodiment is as follows image 3 shown, by image 3 It can be seen that the carbon fiber paper is composed of staggered fiber webs, and the fibers are connected by a small amount of resin carbon.

[0066] The grammage of the carbon fiber paper of this embodiment is 80 g / m 2 , the resistivity is 7.8mΩ·cm, and the air permeability is 1900ml·mm / (cm 2 ·hr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com