High-temperature-resistant niobium-containing vermicular graphite cast iron and preparation method thereof

A technology of vermicular graphite cast iron and high temperature resistance, which is used in the field of high temperature resistant niobium-containing vermicular graphite cast iron and high temperature resistant niobium-containing vermicular graphite cast iron, and can solve the problems of vehicle life and driving safety, difficult materials to meet requirements, fatigue failure fracture and other problems , to achieve the effect of maintaining performance and stability, material performance and performance stability, and improving high temperature resistance and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

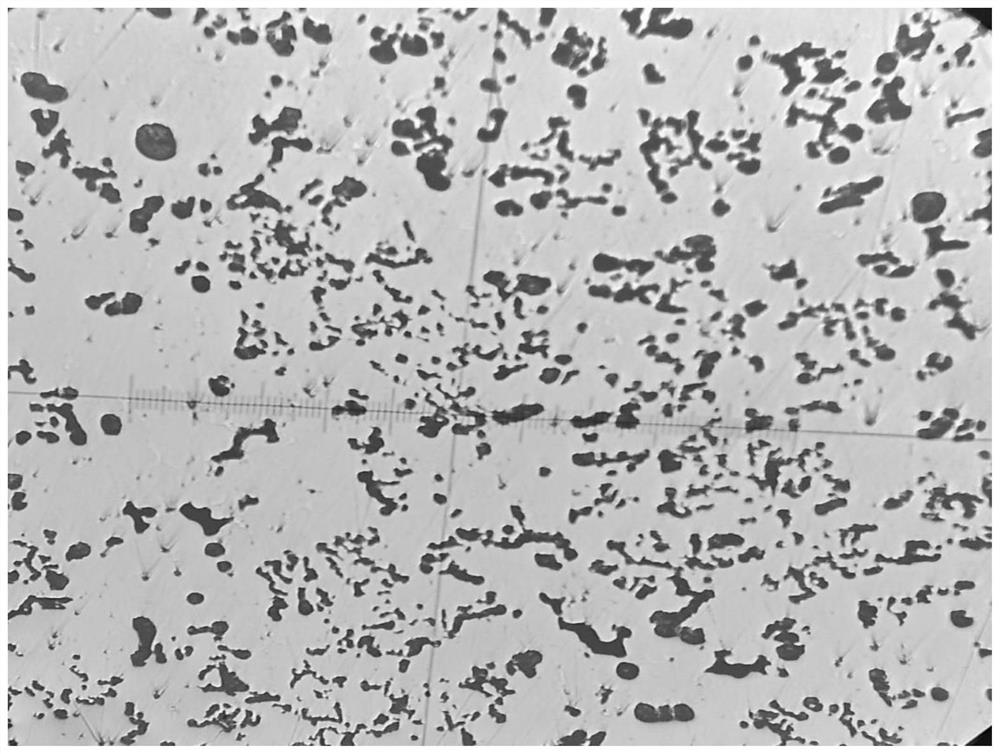

Image

Examples

Embodiment 1

[0043] A kind of preparation method of high temperature resistant niobium-containing vermicular graphite cast iron, is characterized in that, comprises the following steps:

[0044] S1 takes scrap steel, pig iron, and returned iron as the charge, heats up and smelts, and in parts by weight, the addition amounts are: 35 parts of scrap steel, 25 parts of pig iron and 40 parts of returned iron; when 4 / 5 of the mass of the charge is melted, silicon is added. Iron alloys, ferromolybdenum alloys, nickel plates, ferrovanadium alloys and ferroniobium alloys; when the temperature of the charge is 1400-1500° C., take samples to detect the chemical composition with a spectrometer, and keep smelting at the same time until the chemical composition is shown in Example 1 of Table 1. molten iron.

[0045] S2 is covered with rare earth magnesium vermicularizing agent, silicon calcium barium inoculant and rare earth silicon vermicularizing agent uniformly in order in the vermicularization bag, ...

Embodiment 2

[0050] A kind of preparation method of high temperature resistant niobium-containing vermicular graphite cast iron, is characterized in that, comprises the following steps:

[0051] S1 takes scrap steel, pig iron, and returned iron as the charge, heats up and smelts, and in parts by weight, the addition amounts are: 35 parts of scrap steel, 25 parts of pig iron and 40 parts of returned iron; when 4 / 5 of the mass of the charge is melted, silicon is added. Iron alloy, ferromolybdenum alloy, nickel plate, vanadium ferroalloy and niobium ferroalloy; when the charge temperature is 1400-1500 ℃, take a sample to detect the chemical composition, and keep smelting at the same time until the chemical composition is as shown in Example 2 in Table 1, and molten iron is obtained.

[0052] S2 is covered with rare earth magnesium vermicularizing agent, silicon calcium barium inoculant and rare earth silicon vermicularizing agent uniformly in order in the vermicularization bag, and finally the...

Embodiment 3

[0057] A kind of preparation method of high temperature resistant niobium-containing vermicular graphite cast iron, is characterized in that, comprises the following steps:

[0058] S1 takes scrap steel, pig iron, and returned iron as the charge, heats up and smelts, and in parts by weight, the addition amounts are: 35 parts of scrap steel, 25 parts of pig iron and 40 parts of returned iron; when 4 / 5 of the mass of the charge is melted, silicon is added. Iron alloy, ferromolybdenum alloy, nickel plate, vanadium ferroalloy and niobium ferroalloy; when the charge temperature is 1400-1500 ℃, take samples to detect the chemical composition, and keep smelting at the same time until the chemical composition is shown in Example 3 in Table 1, and molten iron is obtained.

[0059] S2 is covered with rare earth magnesium vermicularizing agent, silicon calcium barium inoculant and rare earth silicon vermicularizing agent uniformly in order in the vermicularization bag, and finally the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com