Sauce composite yeast seed and application thereof in sauce preparation

A technology of composite strains and soy sauce, applied in the direction of climate change adaptation, microbe-based methods, microbes, etc., can solve the problems of white spots and high tyrosine content in soybean paste, and reduce the possibility of excessive free amino acids Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

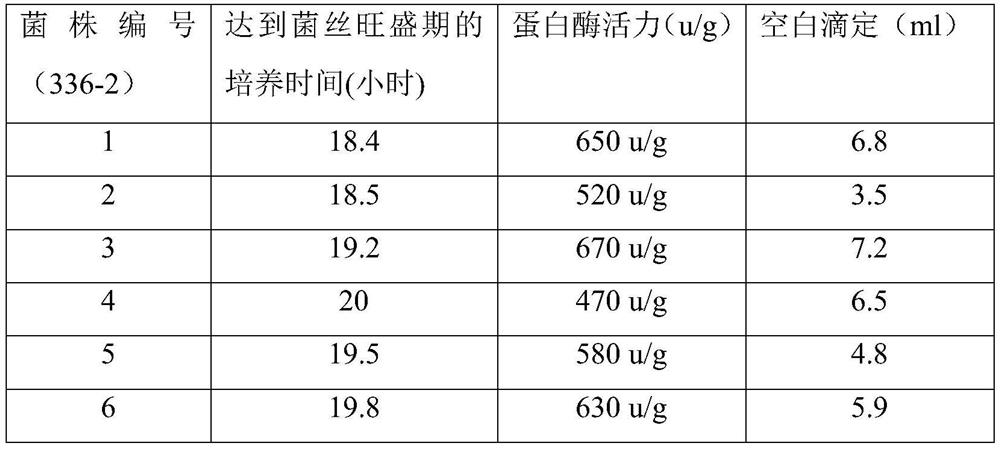

[0031] Example 1. Screening of Aspergillus oryzae strains

[0032] (1) The higher the protease activity, the stronger the enzyme production ability and the higher the protein decomposition ability per unit time. Antibacterial ability is the titer of blank test in protein determination. The lower the blank value, the higher the antibacterial ability. Based on the comprehensive growth rate, protease activity and blank value, the Aspergillus oryzae strain SDKYSW-1# with the fastest growth rate and moderate enzyme production ability and the first anti-miscellaneous bacteria ability was selected. SDKYSW-1# has high spore content, high activity, high protease production, 1100-1300U / g protease activity, fast growth (14-15 hours in the vigorous mycelium period), easy to contaminate bacteria before the vigorous mycelium period, and reaches the hyphae After the vigorous growth period, the flora dominance is completely established, and it is not easy to contaminate the bacteria during t...

Embodiment 2

[0038] Example 2. The effect of the combination of Aspergillus oryzae strains on the koji-making process

[0039] The Aspergillus oryzae strain screened in Example 1 was used for soybean koji-making, and the medium components, culture temperature, and culturing time were controlled, and enzyme activity, growth status, number of miscellaneous bacteria and amino acid nitrogen content were assessed after the koji. Select a combination of enzyme activity between 700-850 U / g.

[0040] The specific steps of the koji-making process are as follows:

[0041] (1) Raw material pretreatment: mix soybeans and water with each other in a ratio of 1:4 by mass fraction, soak for 5-7 hours, wash, and drain excess water;

[0042] (2) Cooking: the drained soybeans are steamed and sterilized, and the sterilization conditions are 121°C and 15min;

[0043] (3) Mixing ingredients: Mix the steamed soybeans and flour evenly in a ratio of 4:1 by mass fraction;

[0044] (4) inoculation: two kinds of A...

Embodiment 3

[0050] Example 3. The effect of the combination of Aspergillus oryzae strains on brewing sauce

[0051] Experimental group: The koji (SDKYSW-1#) prepared in Example 2 was 0.4×10 10 Pieces / g, JP-M01 is 0.36×10 10 pieces / g) and the brine with a concentration of 13% (100 parts by mass of water and 13 parts by mass of salt, fully dissolved and mixed) in a mass ratio of 1:2 (50 parts by mass of koji and 100 parts by mass used to prepare brine) mass parts of water), and fermented in a constant temperature environment of 52-53 ° C for 30 days to obtain soybean paste. Products such as figure 1 shown, no "white dots" appear.

[0052] Control group: Aspergillus oryzae strain SDKYSW-1# (effective viable count 1.0×10 10 Pieces / g) according to the koji-making process in the experimental group to obtain a koji, wherein the inoculation amount of SDKYSW-1# is 0.3‰ of the total mass of the mixture, and then fermented under the same fermentation conditions as the experimental group to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com