Immobilized fermenting method for table vinegar

A technology of immobilized fermentation and immobilized carrier, applied in the direction of microorganism-based methods, biochemical equipment and methods, vinegar preparation, etc., which can solve the problems of fermentation product pollution, reduced post-fermentation efficiency, and low utilization of immobilized cells , to achieve the effect of increasing cell density, not being easily decomposed by microorganisms, and adapting to the fermentation environment earlier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Using cider as raw material, adopting immobilized acetic acid bacteria to carry out repeated batch fermentation to produce apple cider vinegar

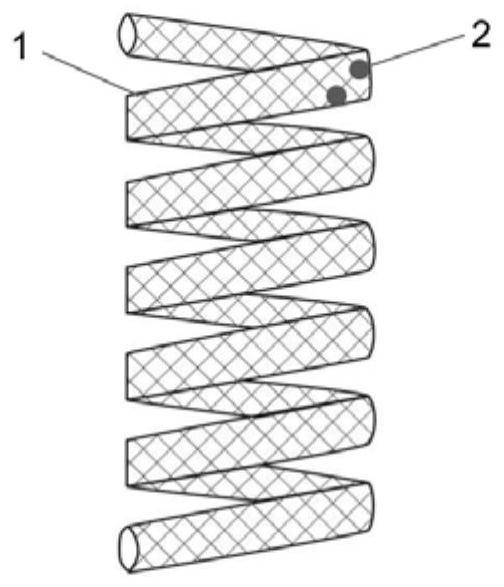

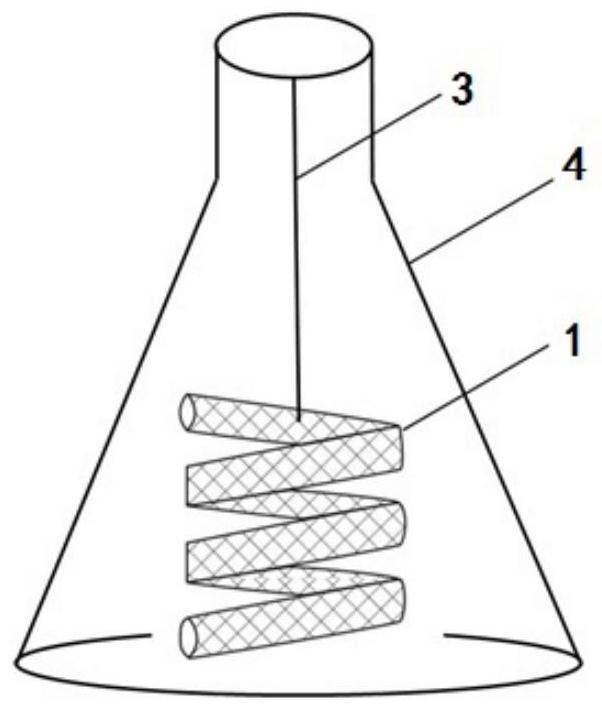

[0030] Such as figure 1 As shown, the 2cm × 2cm water chestnut shell 2 is evenly fixed on the 10cm long spiral barrel-shaped immobilization support 1; as figure 2 As shown, a section of iron wire 3 is welded on the spiral barrel-shaped immobilized support 1, and the other end of the iron wire 3 is bent, hooked on the mouth of the triangular bottle 4, so that the spiral barrel-shaped immobilized support 1 is perpendicular to the bottom of the triangular flask 4. After adding the seed liquid of 0.3L and the alcoholic strength of 0.6L in the bottle, be the cider of 9%vol (obtained by the fermentation of apple juice, containing nutrient salt 0.6g / L for fermentation, glucose 1.4g / L), at a temperature of 28 The immobilization and fermentation of the cells were carried out at -30°C and a rotation speed of 120-150r / min....

Embodiment 2

[0032] Embodiment 2: Taking rice wine as raw material, adopting immobilized acetic acid bacteria to carry out repeated batch fermentation to produce rice vinegar

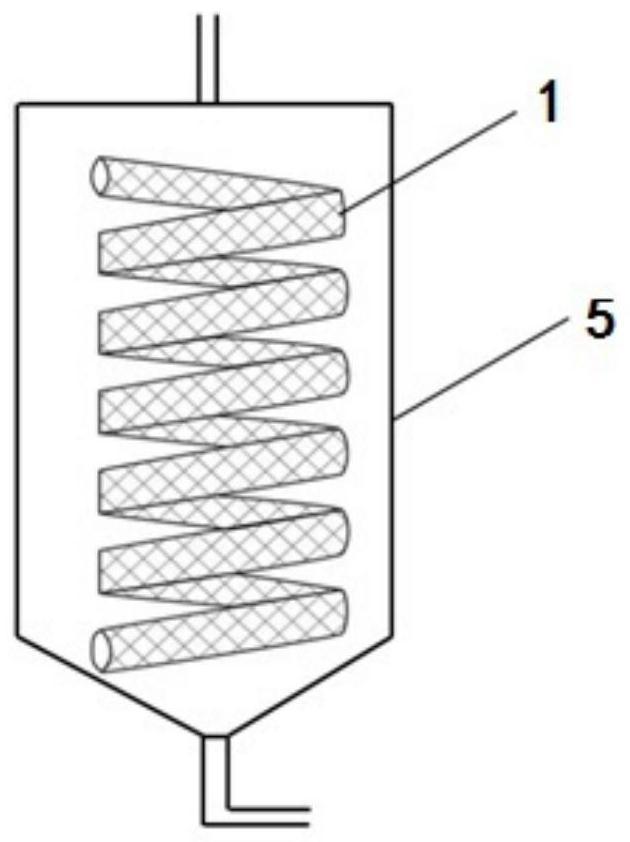

[0033] Evenly fix the bamboo shoots with a size of 4×4cm on the spiral barrel-shaped support of the fermenter. Such as image 3 As shown, place 1 on the spiral barrel-shaped immobilized support in a 50L liquid fermenter 5, add 25L of rice wine with an alcohol content of 5% vol, and insert the seeds in the shake flask according to the inoculation amount of 20% (v / v) Seed medium: glucose 2g / L, peptone 2g / L, yeast extract 1g / L, acetic acid 20ml / L, ethanol 10ml / L. Adjust the ventilation rate to 0.1-0.2vvm, the stirring speed to 120-150r / min, keep the temperature at 28-30°C, and carry out fermentation while immobilizing. Adding 12L alcoholic strength is that 10%vol rice wine is fermented. When the ethanol concentration of the fermented liquid is less than 0.5g / L, remove 1 / 2 volume of the fermented liquid, add 1 / 2 volu...

Embodiment 3

[0035] Embodiment 3: Using edible alcohol as raw material, adopting immobilized acetic acid bacteria to carry out repeated batch fermentation to produce high-acidity white vinegar

[0036]The fermenter and immobilized support are the same as in Example 2. Evenly fix the reed leaves with a size of 4×4cm on the spiral barrel-shaped support of the fermenter, add 25L of edible alcohol solution with 5% alcohol content, 0.9g / L of nutrient salt and 2.5g / L of glucose, according to 30% (v / v) inoculum was inserted into the seed liquid in the shake flask, and the seed medium was: glucose 4g / L, peptone 4g / L, yeast extract 3g / L, acetic acid 40ml / L, ethanol 30ml / L. Adjust the ventilation rate to 0.1-0.2vvm, the stirring speed to 120-150r / min, keep the temperature at 28-30°C, and carry out fermentation while immobilizing. L alcoholic strength is the edible alcohol solution of 15%vol to ferment. When the ethanol concentration of the fermentation broth is less than 1g / L, remove 12.5L volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com