Mechanically reinforced organic silica gel and preparation method thereof

A silicone and mechanical technology, applied in the field of gel and its preparation, can solve the problems of poor mechanical properties of silicone gel, difficulty in maintaining electrical equipment, affecting application performance, etc., achieve good mechanical properties, improve hydrophobic mobility, Effect of improving weather resistance and acid and alkali corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

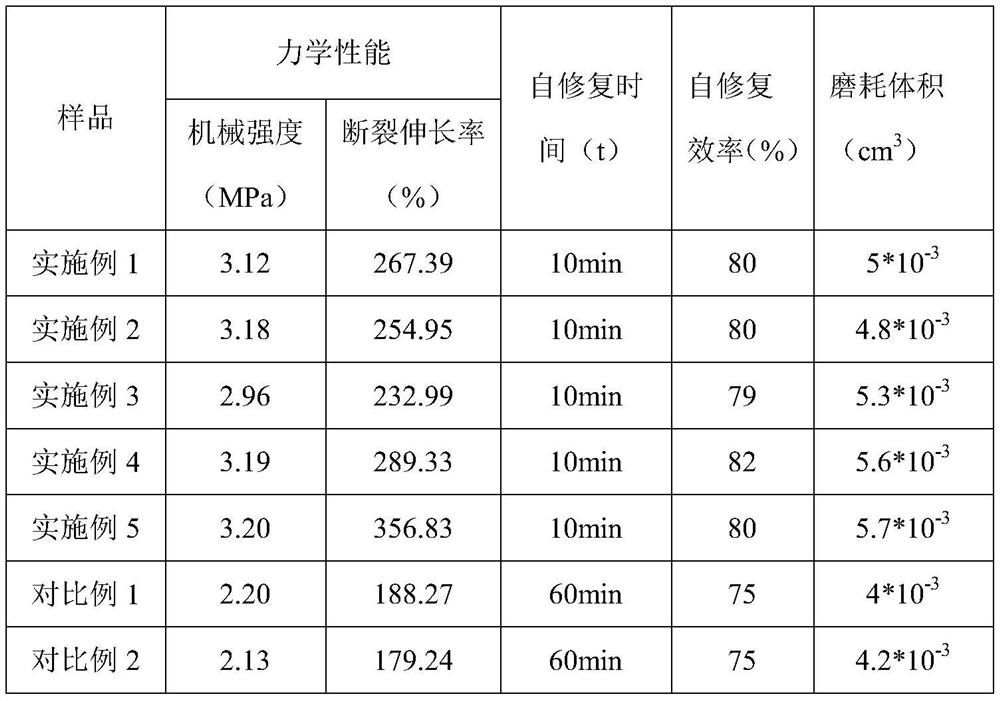

Examples

Embodiment 1

[0024] A mechanically reinforced silicone gel, comprising the following parts by weight of A component: 36 parts of hydrogen-terminated polysiloxane with a viscosity of 13,000cs, 4 parts of 13,000cs hydrogen-containing polysiloxane, and 13,000cs of hydroxyl-terminated fluorine-containing polysiloxane 30 parts of polysiloxane, 20 parts of boric acid, 10 parts of fumed silica, 10 parts of silicon micropowder, 5 parts of boron nitride, 0.02 part of methyl vinyl siloxane; component B: fluorine-terminated polysiloxane 100 parts of alkane, 10 parts of boric acid, 4 parts of γ-methacryloyloxypropyltrimethoxysilane, and 0.02 part of platinum catalyst.

[0025] The above-mentioned mechanically reinforced organosilicon gel for hydroxyl-containing surface is obtained by the following preparation method:

[0026] (1) Thoroughly mix boric acid with hydrogen-terminated polysiloxane with a viscosity of 13,000 cs, hydrogen-containing polysiloxane with a viscosity of 13,000 cs, and hydroxyl-te...

Embodiment 2

[0032] A mechanically reinforced silicone gel, comprising the following parts by weight of A component: 36 parts of hydrogen-terminated polysiloxane with a viscosity of 13,000cs, 14 parts of hydrogen-containing polysiloxane of 13,000cs, and 13,000cs of hydroxyl-terminated fluorine-containing polysiloxane 50 parts of polysiloxane, 5 parts of boric acid, 5 parts of fumed silica, 5 parts of silicon micropowder, 5 parts of boron nitride, 0.01 part of methyl vinyl siloxane; component B: hydroxyl-terminated fluorine-containing polysiloxane 60 parts of alkane, 5 parts of boric acid, 1 part of γ-methacryloyloxypropyltrimethoxysilane, and 0.01 part of platinum catalyst.

[0033] The above-mentioned mechanically reinforced organosilicon gel for hydroxyl-containing surface is obtained by the following preparation method:

[0034] (1) Thoroughly mix boric acid with hydrogen-terminated polysiloxane with a viscosity of 13,000 cs, hydrogen-containing polysiloxane with a viscosity of 13,000 c...

Embodiment 3

[0040] A mechanically reinforced silicone gel, comprising the following parts by weight of A component: 36 parts of hydrogen-terminated polysiloxane with a viscosity of 13000cs, 4 parts of 13000cs hydrogen-containing polysiloxane, and 13000cs of hydroxyl-terminated fluorine-containing polysiloxane 50 parts of polysiloxane, 10 parts of boric acid, 10 parts of fumed silica, 5 parts of silicon micropowder, 5 parts of boron nitride, 0.02 part of methyl vinyl siloxane; component B: fluorine-containing polysiloxane with terminal hydroxyl group 85 parts of alkane, 8 parts of boric acid, 2 parts of γ-methacryloyloxypropyltrimethoxysilane, and 0.01 part of platinum catalyst.

[0041] The above-mentioned mechanically reinforced organosilicon gel for hydroxyl-containing surface is obtained by the following preparation method:

[0042] (1) Thoroughly mix boric acid and hydrogen-terminated polysiloxane with a viscosity of 13,000 cs, hydrogen-containing polysiloxane with a viscosity of 13,0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical performance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com