Hydrate inhibitor and preparation method thereof

A technology of hydrate inhibitors and polymerization reaction products, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems that cannot take into account the inhibition of hydrate formation and clay hydration, and achieve excellent low temperature rheology and inhibition non-toxicity, reduce the degree of scouring, and the effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

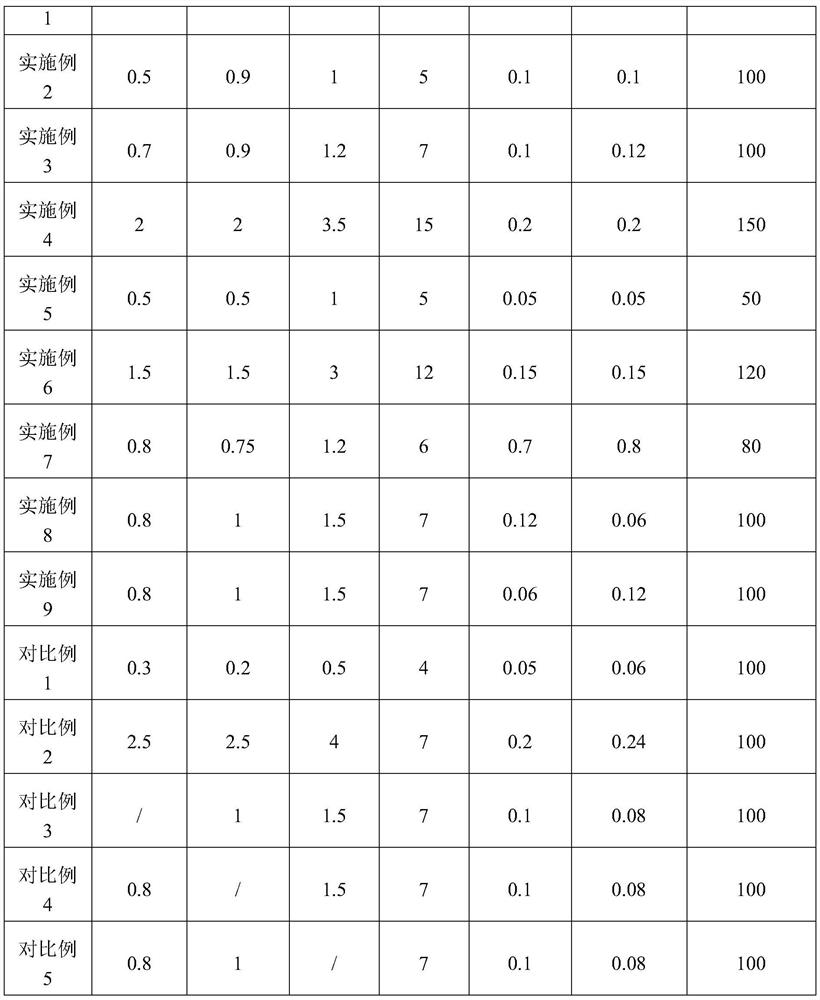

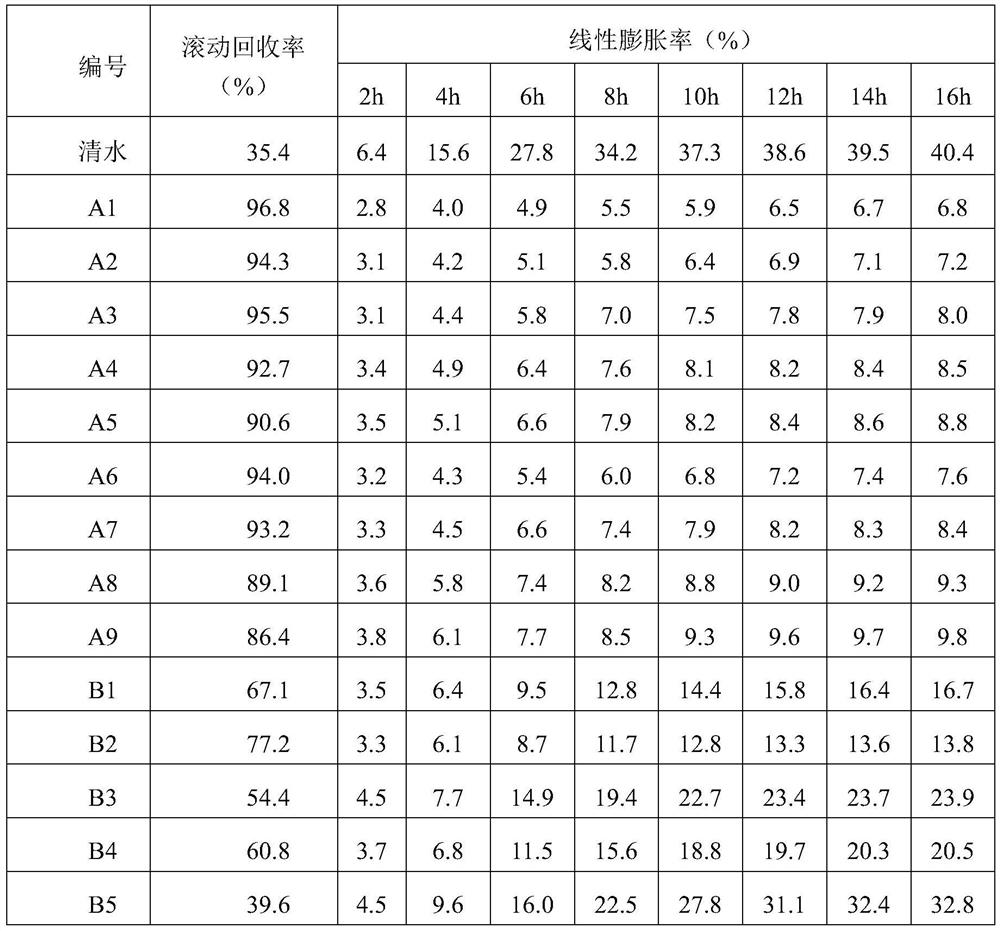

Examples

preparation example Construction

[0033] According to another aspect of the present invention, there is provided a preparation method of the above-mentioned hydrate inhibitor, comprising the following steps:

[0034] S1, mixing and reacting raw materials comprising a sulfonic acid-based monomer, a monomer having a lactam cyclic structure, a cationic monomer, an initiator and water to obtain a first crude product;

[0035] S2, mixing the first crude product with an inorganic salt to obtain a hydrate inhibitor.

[0036] The hydrate inhibitor obtained by the above preparation method of the present invention has excellent low-temperature rheology and inhibition, can maintain stable performance under the conditions of -5°C to 50°C, and can effectively reduce the scouring degree of drilling fluid on the formation. It can solve the problem of wellbore instability caused by clay hydration in the drilling process; and the inhibitor has dual inhibition effects of thermodynamics and kinetics, which can not only change the ...

Embodiment 1

[0059] The present embodiment provides a method for preparing a low-temperature hydrate drilling fluid inhibitor, and the specific steps are as follows:

[0060] (1) take by weighing 2.5g triethanolamine and 150 parts by weight of ethanol and place in the round-bottomed flask that reflux condenser is housed to mix, obtain solution a, logical nitrogen deoxygenation 30 minutes under stirring condition, then be heated to be warming up to 70 ℃, Weigh 2.0 g of bromopropene and add it to solution a and stir and mix to obtain solution b. The reaction was carried out under condensation reflux conditions for 24 hours to obtain crude product A. The crude product A was cooled to room temperature, and ethyl acetate and absolute ethanol were used under low temperature conditions. The mixed solvent is recrystallized to obtain a white powder to obtain a product B, and the product B is dried in a vacuum drying oven at 45° C. under vacuum conditions to obtain a product C, that is, a cationic mo...

Embodiment 2

[0064] The present embodiment provides a method for preparing a low-temperature hydrate drilling fluid inhibitor, and the specific steps are as follows:

[0065] (1) take by weighing 2.5g triethanolamine and 150 parts by weight of ethanol and place in the round-bottomed flask that reflux condenser is housed to mix, obtain solution a, logical nitrogen deoxygenation 30 minutes under stirring condition, then be heated to be warming up to 70 ℃, Weigh 2.0 g of bromopropene and add it to solution a and stir and mix to obtain solution b. The reaction was carried out under condensation reflux conditions for 24 hours to obtain crude product A. The crude product A was cooled to room temperature, and ethyl acetate and absolute ethanol were used under low temperature conditions. The mixed solvent is recrystallized to obtain a white powder to obtain a product B, and the product B is dried in a vacuum drying oven at 45° C. under vacuum conditions to obtain a product C, that is, a cationic mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com