Sand core material for brake disc casting mold as well as preparation method and application of sand core material

A technology of casting molds and brake discs, which is applied in the direction of manufacturing tools, casting molding equipment, cleaning/processing machinery of casting materials, etc., can solve problems such as potential safety hazards, achieve improved ablation resistance, good yield, The effect of ensuring dimensional accuracy and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

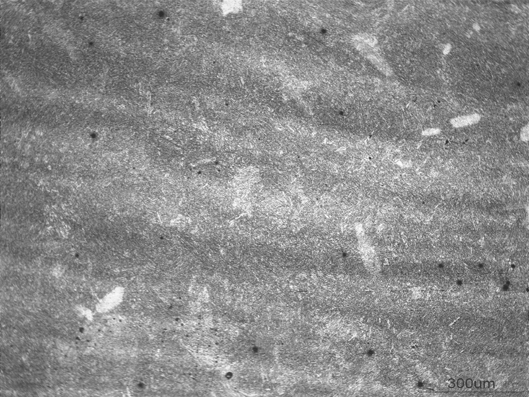

Image

Examples

Embodiment 1

[0038] A sand core material for a brake disc casting mold, comprising 20 parts by weight of ceramic sand, 70 parts by weight of quartz calcined sand, 1.0 part by weight of carbon nanotube-modified phenolic resin, 0.12 part by weight of taurine, 0.08 part by weight parts of calcium stearate, 0.01 part by weight of aminocarboxylate-based silane coupling agent and 0.01 part by weight of sodium nitrate.

[0039] The refractoriness of the ceramic sand is greater than or equal to 1750°C, and the expansion coefficient is less than or equal to 0.7%. Ceramic sand is sintered, and the main component is aluminum oxide.

[0040] Quartz calcined sand is obtained by heating quartz sand at high temperature.

[0041] The preparation method of the carbon nanotube modified phenolic resin is:

[0042] S01, the phenolic resin weighing 95% by mass percentage is added in the ethanol to dissolve completely, and the added weight of the ethanol is equivalent to 2 times the amount of the phenolic res...

Embodiment 2

[0056] A sand core material for a brake disc casting mold, comprising 30 parts by weight of ceramic sand, 70 parts by weight of calcined quartz sand, 1.1 parts by weight of carbon nanotube-modified phenolic resin, 0.132 parts by weight of adipic acid, 0.088 parts by weight parts of magnesium stearate, 0.011 parts by weight of aminopropylsilane coupling agent and 0.011 parts by weight of sodium nitrite.

[0057] The refractoriness of the ceramic sand is greater than or equal to 1750°C, and the expansion coefficient is less than or equal to 0.7%. Ceramic sand is sintered, and the main component is aluminum oxide.

[0058] Quartz calcined sand is obtained by heating quartz sand at high temperature.

[0059] The preparation method of the carbon nanotube modified phenolic resin is:

[0060] S01, the phenolic resin weighing 95.5% by mass percentage is added in ethanol to dissolve completely, and the added weight of ethanol is equivalent to 3 times the amount of the phenolic resin;...

Embodiment 3

[0070] A sand core material for a brake disc casting mold, comprising 30 parts by weight of ceramic sand, 70 parts by weight of calcined quartz sand, 1.2 parts by weight of carbon nanotube-modified phenolic resin, 0.144 parts by weight of adipic acid, 0.096 parts by weight parts of barium stearate, 0.012 parts by weight of an aminocarboxylate-based silane coupling agent, and 0.012 parts by weight of potassium nitrate.

[0071] The refractoriness of the ceramic sand is greater than or equal to 1750°C, and the expansion coefficient is less than or equal to 0.7%. Ceramic sand is sintered, and the main component is aluminum oxide.

[0072] Quartz calcined sand is obtained by heating quartz sand at high temperature.

[0073] The preparation method of the carbon nanotube modified phenolic resin is:

[0074] S01, the phenolic resin weighing 96% by mass percentage is added in ethanol to dissolve completely, and the added weight of ethanol is equivalent to 5 times the amount of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com