High-fluidity phosphate inorganic binder sand and preparation method thereof

An inorganic binder, high fluidity technology, applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of low casting efficiency, poor fluidity, poor casting quality, etc., to improve fluidity and collapse Good, high-intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] First add 14 parts of aluminum hydroxide and 26 parts of water into the container, start the electromagnetic stirrer, adjust the temperature of the heating equipment to 120°C to heat the container, and when the liquid temperature is 98°C to 100°C, then add 100°C to the container Parts of phosphoric acid with a concentration of 70%, continue to heat until the solution is clear, at this time the solution temperature is 106°C to 108°C, keep the temperature, then slowly add 8 parts of boric acid, react until the solution becomes transparent, then add 5 parts of citric acid, the solution is clarified again Afterwards, the heating can be stopped, the agitator is closed, and the phosphate inorganic binder is obtained when the solution is naturally cooled to room temperature. In the prepared phosphate inorganic binder, the weight percentages of each component are aluminum hydroxide 11%, 70% phosphoric acid 49%, boric acid 4%, citric acid 3%, water 33%;

[0032] Take 1 part of 1...

Embodiment 2

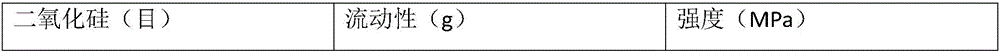

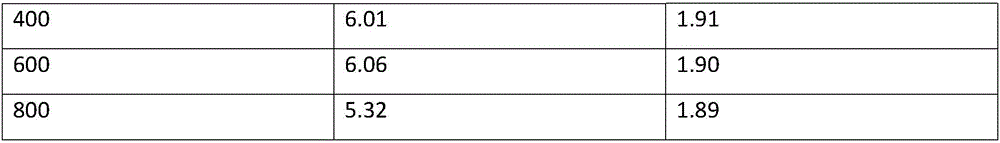

[0035] Under the condition that the experimental method remains unchanged, change the data of some experimental materials, that is, only change the composition ratio of the additive. When making the additive, take 1 part of l-61 and mix it with water in a certain proportion, and then add 3 parts with a particle size of 600 The purpose silica is made into an additive;

[0036] The fluidity of the phosphate inorganic binder sand was tested by the hammering method, and the fluidity of the sample reached 5.96g; a number of "8" standard block samples were made on the SAC hammering type sample making machine, and then the temperature was 155 ° C. After being baked in a heating furnace for 23 minutes, the resulting tensile strength at room temperature was 1.92 MPa.

Embodiment 3

[0038] Under the condition that the experimental method remains unchanged, change the data of some experimental materials, that is, only change the composition ratio of the additive. When making the additive, take 1 part of l-61 and mix it with water in a certain proportion, and then add 5 parts of it with a particle size of 600 The purpose silica is made into an additive;

[0039] The fluidity of the phosphate inorganic binder sand was tested by the hammering method, and the fluidity of the sample reached 6.05g; a number of "8" standard block samples were made on the SAC hammering type sample making machine, and then the temperature was 155 ° C. After being baked in a heating furnace for 23 minutes, the resulting tensile strength at room temperature was 1.81 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com