TiAl alloy plate rolling method and device

An alloy plate and alloy technology, applied in metal rolling, driving devices for metal rolling mills, metal rolling, etc., can solve the problems of TiAl plate bending and fracture, unfavorable rolling of large-size plates, etc., and achieve rolling passes Less, good industrial application potential, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

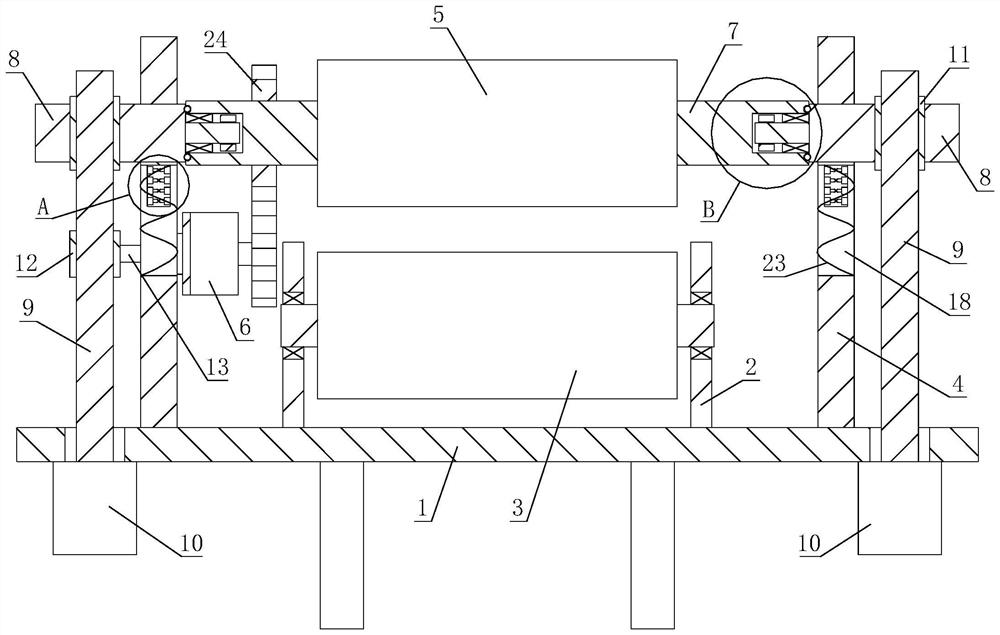

[0048] The rolling process of TiAl alloy plate is as follows:

[0049] 1. The thickness of the upper and lower stainless steel lining plates is 20mm, and the thickness of the TiAl alloy slab is 10mm, and two 304 stainless steel lining plates are placed on the upper and lower surfaces of the TiAl alloy respectively; the TiAl alloy slab is directly from the TiAl alloy ingot. It is made by cutting TiAl alloy slabs of different thicknesses.

[0050] 2. Put the TiAl alloy and the liner into the heating box for heating at the same time; after the temperature is raised to 1200°C, keep the temperature for 120min;

[0051] 3. Push the liner and TiAl alloy to the entrance of the rolling device (the position between the roll and the fixed roll) at the same time; perform single-pass rolling with a deformation of 60% and a rolling speed of 140 mm / s;

[0052] 4. The rolled TiAl alloy sheet is kept at a temperature of 900° C. for 7 hours, and then cooled to room temperature with the furnace...

Embodiment 2

[0055] The rolling process of TiAl alloy plate is as follows:

[0056] 1. The thickness of the upper and lower stainless steel lining plates is 10mm, the thickness of the TiAl alloy slab is 20mm, and two 304 stainless steel lining plates are placed on the upper and lower surfaces of the TiAl alloy respectively;

[0057] 2. Put the TiAl alloy and the liner into the heating box for heating at the same time; after the temperature is raised to 1250 ℃, let it stand for 90 minutes;

[0058] 3. Push the liner and billet to the entrance of the roll at the same time; carry out single-pass rolling with a deformation of 70%, and a rolling speed of 90mm / s;

[0059] 4. The rolled TiAl alloy sheet is kept for 6 hours at a temperature of 950°C, and then cooled to room temperature with the furnace.

[0060] A picture of the final rolled TiAl alloy sheet as Figure 7 , the SEM-BSE image of its cross-section is shown in Figure 10 shown.

Embodiment 3

[0062] 1. The thickness of the upper and lower stainless steel linings is 20mm, and the thickness of the TiAl alloy slab is 20mm, and two 304 stainless steel linings are placed on the upper and lower surfaces of the TiAl alloy respectively;

[0063] 2. Put the TiAl alloy and the lining plate into the heating box for heating at the same time; after the temperature is raised to 1300 ℃, let stand for 50 minutes;

[0064] 3. Push the liner and billet to the entrance of the roll at the same time; carry out single-pass rolling with a deformation of 80% and a rolling speed of 40mm / s;

[0065] 4. The rolled TiAl alloy sheet is kept at a temperature of 1100° C. for 4 hours, and then cooled to room temperature with the furnace.

[0066] A picture of the final rolled TiAl alloy sheet as Figure 8 , the SEM-BSE image of its cross-section is shown in Figure 11 shown.

[0067] TiAl alloy sheets rolled according to Examples 1-3 and Figures 9 to 11 It can be seen from the SEM image that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com