Preparation method of VOCs catalytic oxidation catalyst and obtained catalyst

A catalytic oxidation and catalyst technology, which is applied in the field of VOCs treatment, can solve the problems of low activity, scarce resources, and easy poisoning of VOCs, and achieve the effects of uniform pore distribution, increased specific surface area, and improved catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

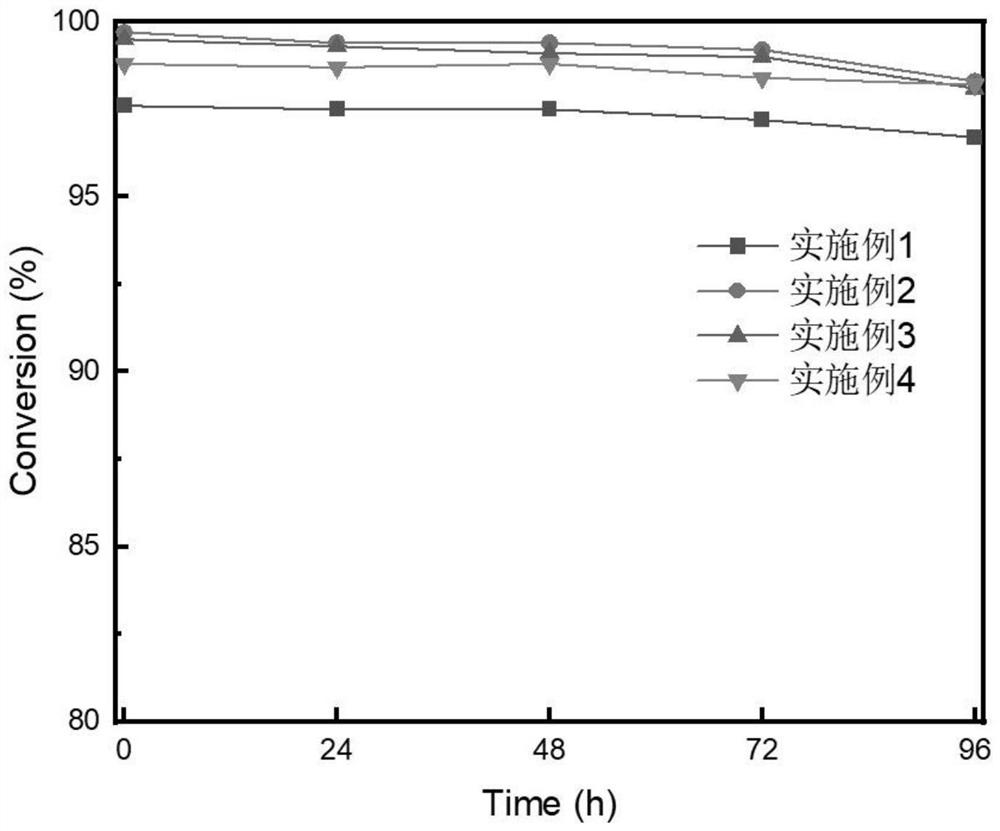

[0031] see figure 1 , a preparation method of a VOCs catalytic oxidation catalyst, comprising the following steps:

[0032] Acid etching: acid etching the carrier; drying; obtaining the acid etching carrier; the pH of the acid used is 4~6, the acid etching time is 0.5~4h, and the acid etching temperature is 20~80℃; the drying time is 6~12h, and the drying temperature 80-120°C (in this embodiment, the pH of the acid used is 5, the acid etching time is 2h, and the acid etching temperature is 60°C; the drying time is 10h, and the drying temperature is 100°C).

[0033] Coating roasting: coating a coating material on the surface of the acid-etched carrier; drying; roasting to obtain a coated carrier; the drying temperature is 80-120°C, and the drying time is 2-6h; the roasting temperature is 300-600°C , the roasting time is 2~6h, and the roasting heating rate is 2~8℃ / min (in this embodiment, the drying temperature is 100℃, and the drying time is 2h; the roasting temperature is 600...

Embodiment 2

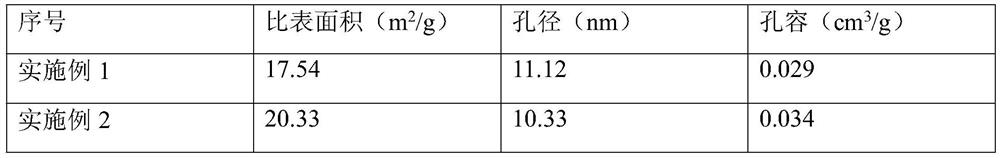

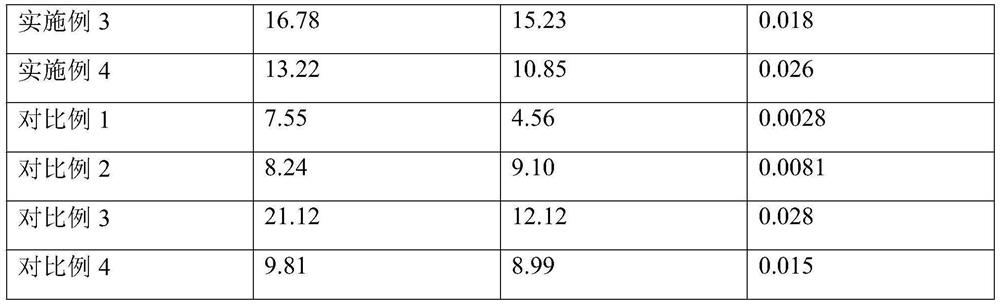

[0046] Example 2: The difference from Example 1 is that the amount of the coating material is 25% of the weight of the acid-etched carrier; the loading amount of the precursor solution is 40% of the weight of the coating carrier; The molar ratio of diaspore, niobium salt, yttrium salt and strontium salt is 8:1:1:0.5; the metal element in the coating material accounts for 11% of the total mass of the coating material; the manganese salt, vanadium salt, The molar ratio of molybdenum salt and nickel salt is 2:5:1.5:0.5; the total concentration of metal ions in the precursor solution is 3.5mol / L.

Embodiment 3

[0047] Example 3: The difference from Example 1 is that the amount of the coating material is 28% of the weight of the acid-etched carrier; the loading amount of the precursor solution is 20% of the weight of the coating carrier; The molar ratio of diaspore, niobium salt, yttrium salt and strontium salt is 9:1.5:1.5:1; the metal element in the coating material accounts for 18% of the total mass of the coating material; the manganese salt, vanadium salt, The molar ratio of molybdenum salt and nickel salt is 3:7:2:1; the total concentration of metal ions in the precursor solution is 5mol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com