Steel sheet and steel pipe

A steel plate and plate thickness technology, applied in the field of steel plates and steel pipes, can solve the problems of reduced surface hardness, slowed surface cooling rate, and insufficient central structure control, etc., to achieve excellent SSC resistance, HIC resistance, and excellent low temperature toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( Embodiment 1

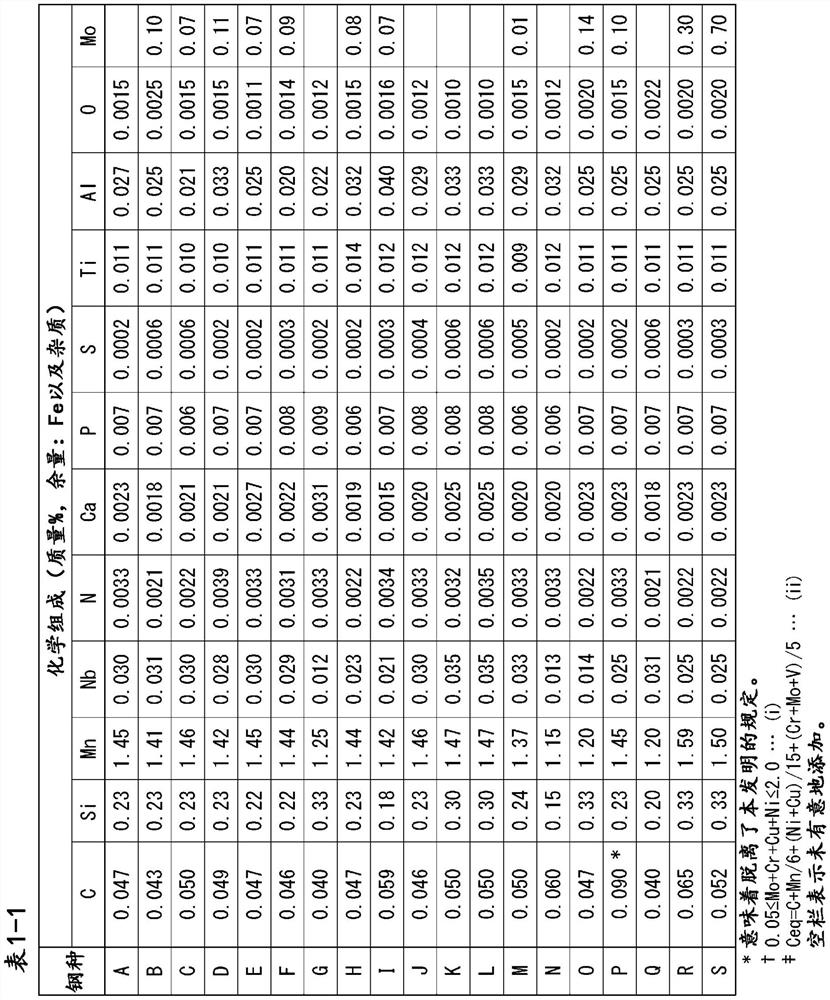

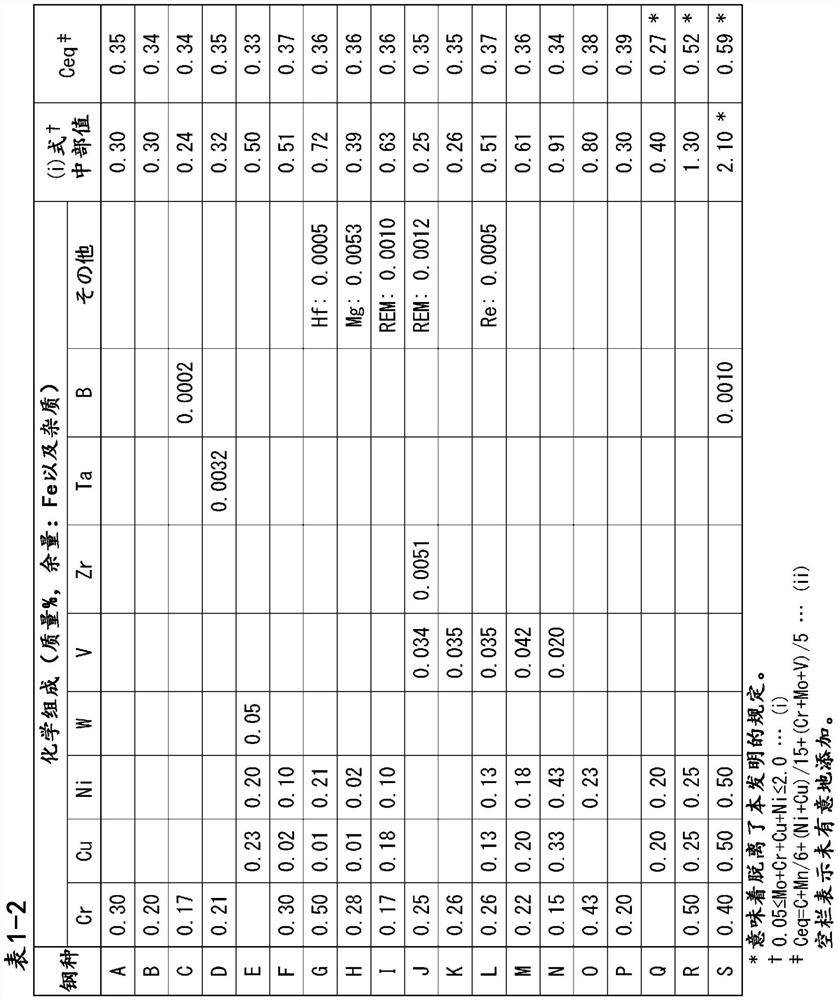

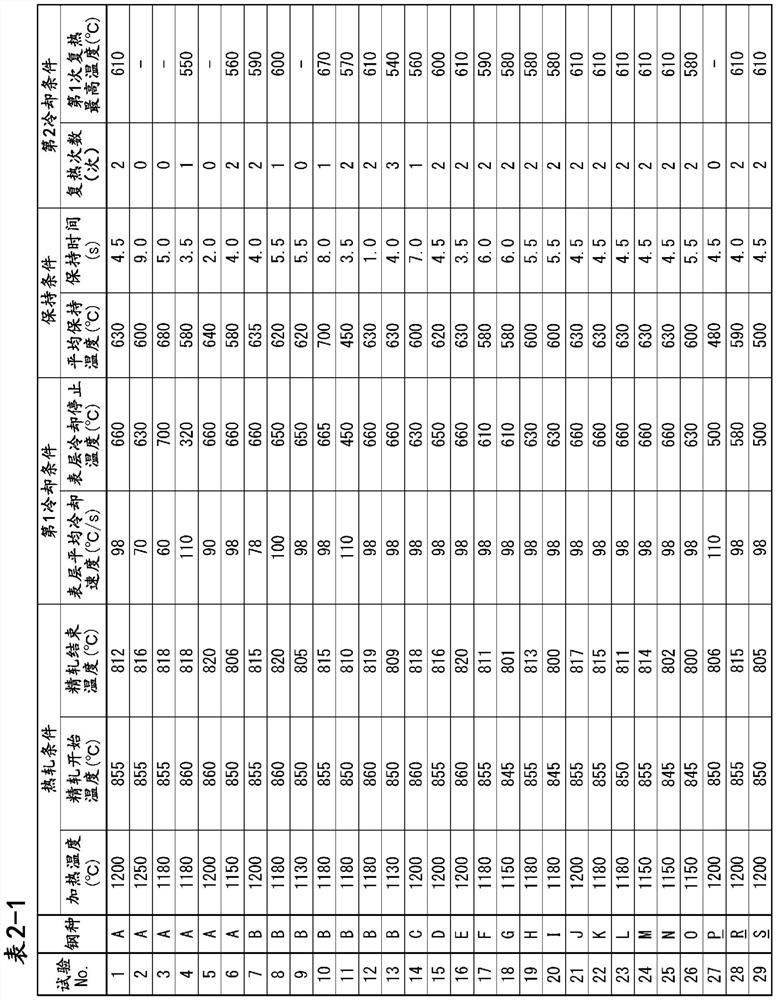

[0234] Steels having the chemical compositions shown in Table 1-1 and Table 1-2 were melted and continuously cast to obtain billets. For the thickness at this time, steel types J to N were set to 300 mm, and other steel types A to I and O to S were set to 240 mm. As shown in Tables 2-1 and 2-3, the obtained slabs were heated to a temperature range of 1100 to 1250°C, hot rolled in a recrystallization temperature range exceeding 900°C, and then subjected to Ar3 to 900°C. In the hot rolling (finishing rolling) in the non-recrystallization temperature region, the hot rolling was completed at the temperature shown in Table 2-1 and Table 2-3, which is the temperature (° C.) of Ar3 or higher.

[0235] After that, for some examples, the first cooling step, the holding step, the third cooling step, and the fourth cooling step were sequentially performed under the conditions shown in Tables 2-1 to 2-4, and thereafter, cooling and cooling were repeated. The steel sheet was produced by c...

Embodiment 2

[0278] Among the steel sheets obtained in Example 1, a steel sheet having preferable properties was formed into a tubular shape by the UO pipe-making method, welded from the inner and outer surfaces of the steel pipe by submerged arc welding, and expanded to obtain a UOE steel pipe. Regarding the welding conditions, the inner surface side was made into three electrodes, the outer surface side was made into four electrodes, and the heat energy was set in the range of 2.0 kJ / mm to 10 kJ / mm according to the plate thickness.

[0279] The obtained steel pipe was subjected to metallographic observation, effective crystal grain size measurement, tensile test, surface hardness measurement, DWTT test, Charpy impact test, SSC test, and HIC test in the same manner as the steel sheet.

[0280] However, as for the observation plane of the metal structure in the steel pipe, so that the L (long side) direction cross section becomes the observation plane, two full-thickness samples are cut out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com