Flexible copper-clad plate graphene oxide hole metallization method

A technology of flexible copper clad laminate and hole metallization, which is applied in the direction of electrical connection formation of printed components, can solve the problems of poor conductivity of the conductive layer, limited conductivity of the polymer conductive layer, waste products, etc., to avoid waste and pollute the environment, The effect of saving human resource costs and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The specific process steps of metallizing the graphene oxide holes of the flexible copper clad laminate of the present invention are as follows:

[0043] The first step is to use ultraviolet laser drilling to drill several through holes on the flexible copper clad plate; use a 355nm picosecond ultraviolet laser drilling machine, the power of the ultraviolet laser drilling machine is 4.5W, the scanning speed is 50mm / s, repeat The number of drillings is 4 times.

[0044] In the second step, the perforated flexible copper clad laminate is washed with circulating water, and then the through hole of the flexible copper clad laminate is processed with a hole-forming agent polyacrylamide. The concentration range of the pore-forming agent is 20wt%, the pH value range is 10, and the set temperature is 35°C. Ultrasonic treatment was used during the whole hole treatment, and the frequency was 45 kHz.

[0045] The 3rd step, add the graphite solid powder of 2g in the sulfuric acid...

Embodiment 2

[0051] The difference from Example 1 is that the black hole treatment time is 4 minutes, and other operations are the same as those of Example 1.

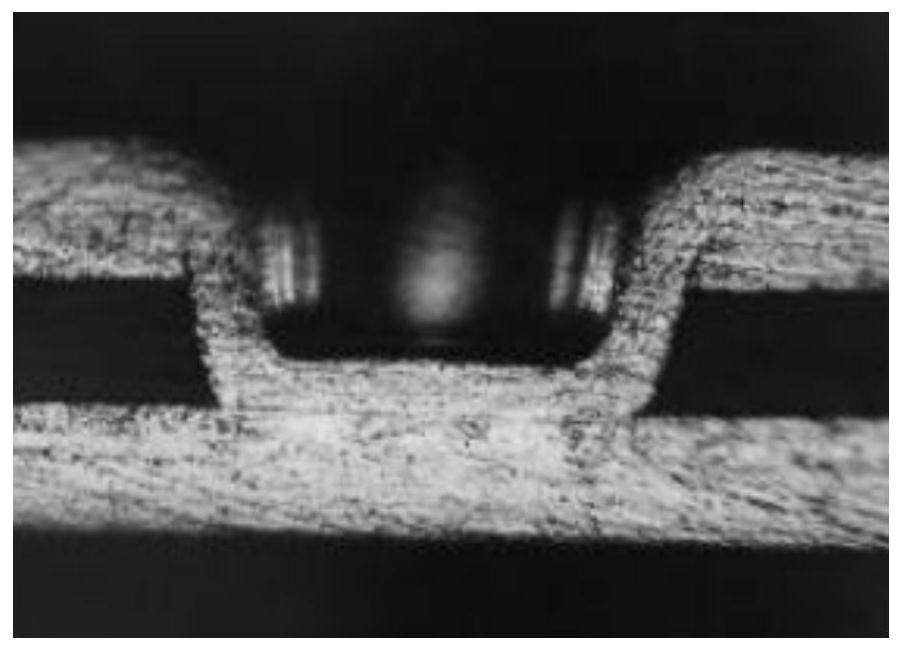

[0052] Graphene oxide conducts black hole treatment on the hole wall of the flexible copper clad laminate for 4 minutes, and the hole wall is electroplated with copper layer such as figure 2 As shown in the figure, the bottom of the hole is round and complete, without black spots, the copper thickness of the hole is uniform, and there is no void or delamination, which is the best group of black holes.

Embodiment 3

[0054] The difference from Example 1 is that the black hole treatment time is 6 minutes, and other operations are the same as those of Example 1.

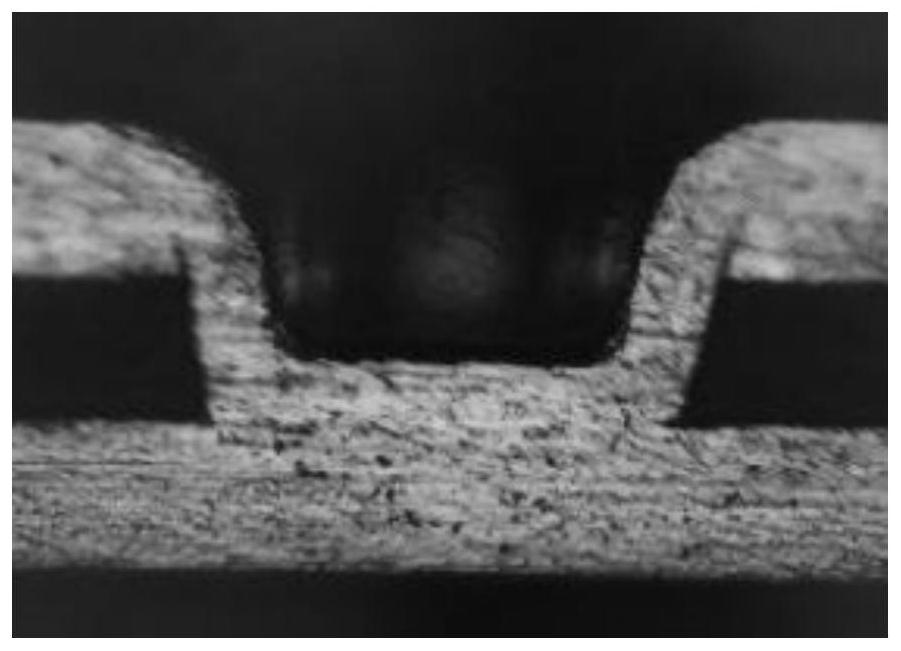

[0055] Graphene oxide conducts black hole treatment on the hole wall of the flexible copper clad laminate for 6 minutes, and the hole wall is electroplated with copper layer such as image 3 As shown in the figure, the bottom of the hole is round and complete, with a few black spots, the copper thickness of the hole is uniform, there is no void, no delamination, and there are some defects at the orifice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com