Preparation method of MXene conductive paper and paper battery

A paper battery, conductive paper technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, non-aqueous electrolyte battery electrodes, etc. The influence of additives on the conductive properties and other issues can achieve the effects of high mechanical strength and chemical stability, improved battery capacity and service life, and uniform conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

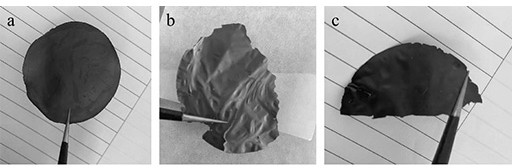

[0027] Preparation of a flexible MXene conductive paper and paper battery

[0028] Dissolve 1 g of LiF in 10 mL of 6 M HCl and mix the solution well. Then, within 30 minutes, 1 gTi 3 AlC 2 The powder is gradually added to the mixed solution to avoid initial overheating. The reaction was continuously stirred at 35°C for 24 hours. The resulting precipitate was washed and centrifuged alternately until the pH of the washing solution was >6. The precipitate was vacuum filtered through a nylon membrane and then naturally dried, and then called multilayer MXene (m-Ti3 C 2 T x ). To delaminate the nanosheets, 0.5 g of m-Ti was 3 C 2 T x The powder was dispersed in 150 mL of deionized water (DI-water). After sonication for 1 h, followed by centrifugation at 3500 rpm for 10 min, a stable colloidal solution was obtained, which was rich in monolayers with few layers of Ti 3 C 2 T x Nanosheets. Ti 3 C 2 T x The colloidal solution was directly vacuum filtered through a poly...

Embodiment 2

[0030] Preparation of a flexible MXene conductive paper and paper battery

[0031] Dissolve 1 g of LiF in 10 mL of 6 M HCl and mix the solution well. Then, within 30 minutes, 1 gTi 3 AlC 2 The powder is gradually added to the mixed solution to avoid initial overheating. The reaction was continuously stirred at 35°C for 24 hours. The resulting precipitate was washed and centrifuged alternately until the pH of the washing solution was >6. The precipitate was vacuum filtered through a nylon membrane and then naturally dried, and then called multilayer MXene (m-Ti 3 C 2 T x ). The prepared m-Ti 3 C 2 T x Disperse 100 mg of the powder into the lining of a hydrothermal kettle of 50 ml of saturated urea solution at 60 °C, and stir magnetically for 3 hours at 60 °C to obtain a uniform mixture. Then, the hydrothermal reactor was reacted at 180°C for 12h. After the reaction was completed, the pH was continuously washed with deionized water until the pH was about 7. Then the r...

Embodiment 3

[0033] Preparation of a flexible MXene conductive paper and paper battery

[0034] Dissolve 1 g of LiF in 10 mL of 6 M HCl and mix the solution well. Then, within 30 minutes, 1 gTi 3 AlC 2 The powder is gradually added to the mixed solution to avoid initial overheating. The reaction was continuously stirred at 35°C for 24 hours. The resulting precipitate was washed and centrifuged alternately until the pH of the washing solution was >6. The precipitate was vacuum filtered through a nylon membrane and then naturally dried, and then called multilayer MXene (m-Ti 3 C 2 T x ). First, the prepared Ti 3 C 2 The powder and thiourea (mass ratio 1:3) were ground and mixed uniformly, then placed in a tube furnace under Ar atmosphere, heated to 500 °C, kept for 3 h, cooled to room temperature, and the prepared material was ground again and used Repeated washing with ionized water until neutral. The obtained powder is dried to obtain N, S co-doped Ti 3 C 2 , denoted as N,S-Ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com