Ultrathin photosensitive resin coating and preparation method thereof

A photosensitive resin and coating technology, applied in the field of ultra-thin photosensitive resin coating and its preparation, can solve the problems of short service life, aging of spectacle frames, insufficient color change, etc., achieve the stability of the light open-loop body, and improve the light fatigue. The effect of prolonging the life of photosensitive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

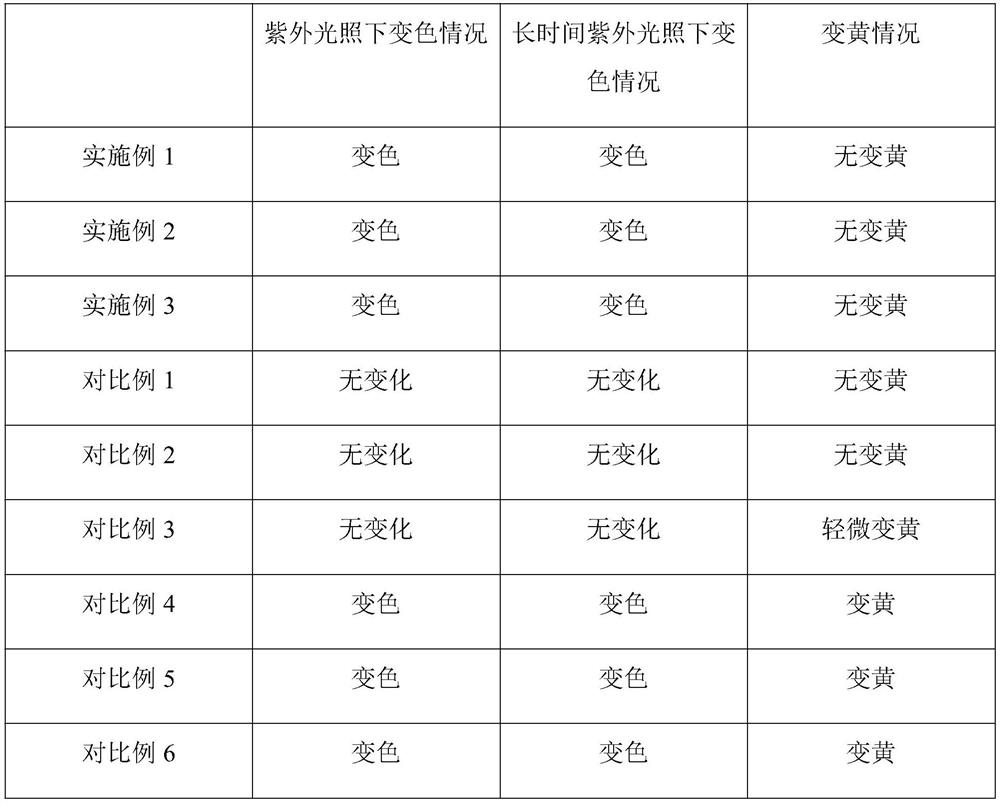

Examples

Embodiment 1

[0032] A preparation method of an ultra-thin photosensitive resin coating, the preparation method of the ultra-thin photosensitive resin coating comprises the following preparation steps:

[0033] (1) Wash the spectacle frames with acetone and anhydrous ethanol for 11 min at 25 kHz in turn to obtain pre-treated spectacle frames; place the pre-treated spectacle frames in an ion thinning apparatus with a bombardment energy of 1keV, and evacuate to 3.2×10 -3 Pa, pass argon at 20sccm, under argon atmosphere, bombard at 15° for 15s, and then at 3° for 8s; mix polyethersulfone, N-methylpyrrolidone and polyvinylpyrrolidone in a mass ratio of 1:4:0.2 Mix, grind at 14 rpm for 9 hours, add copper powder 6 times the mass of polyethersulfone, grind at the same speed for 50 hours, and vacuum for 33 minutes to obtain copper slurry; use copper slurry as spinning solution, spin to the thickness of the film layer After drying at 40°C for 10h, under a hydrogen atmosphere, the temperature was ra...

Embodiment 2

[0041] A preparation method of an ultra-thin photosensitive resin coating, the preparation method of the ultra-thin photosensitive resin coating comprises the following preparation steps:

[0042] (1) Wash the spectacle frames with acetone and anhydrous ethanol for 8 min in turn at 30 kHz to obtain pretreated spectacle frames; place the pretreated spectacle frames in an ion thinning apparatus with a bombardment energy of 3keV, and vacuumize to 4.4×10 -3 Pa, pass argon gas at 25sccm, under argon atmosphere, bombardment at 19° for 21s, and then bombardment at 6° for 12s; polyethersulfone, N-methylpyrrolidone and polyvinylpyrrolidone are mixed in a mass ratio of 1:4:0.3 Mixing, grinding at 25rpm for 6.5h, adding copper powder with 8.5 times the mass of polyethersulfone, grinding at the same speed for 47h, vacuuming for 46min to obtain copper slurry; using copper slurry as spinning solution, spinning to the membrane layer The thickness is 230 μm. After drying at 45 °C for 7 hours,...

Embodiment 3

[0050] A preparation method of an ultra-thin photosensitive resin coating, the preparation method of the ultra-thin photosensitive resin coating comprises the following preparation steps:

[0051] (1) At 35kHz, wash the spectacle frame with acetone and anhydrous ethanol for 5min in turn to obtain the pretreated spectacle frame; place the pretreated spectacle frame in an ion thinning apparatus with a bombardment energy of 6keV, and evacuate to 5.6×10 -3 Pa, pass argon at 30sccm, under argon atmosphere, bombardment at 23° for 27s, and then at 9° for 17s; polyethersulfone, N-methylpyrrolidone and polyvinylpyrrolidone in a mass ratio of 1:4:0.4 Mix, grind at 36 rpm for 4 hours, add copper powder 11 times the mass of polyethersulfone, grind at the same speed for 44 hours, and then vacuumize for 59 minutes to obtain copper slurry; use copper slurry as spinning solution, spin to the thickness of the film layer After drying at 50°C for 4h, under a hydrogen atmosphere, the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com