A photosensitive antibacterial biodegradable 3D printing wire and its preparation method

A 3D printing and biodegradable technology, applied in stretch spinning, additive processing, melt spinning, etc., can solve problems such as heat shrinkage defects, low thermal deformation temperature, strength and toughness to be improved, etc., to reduce production. cost, enhanced dimensional stability, and the effect of broadening application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

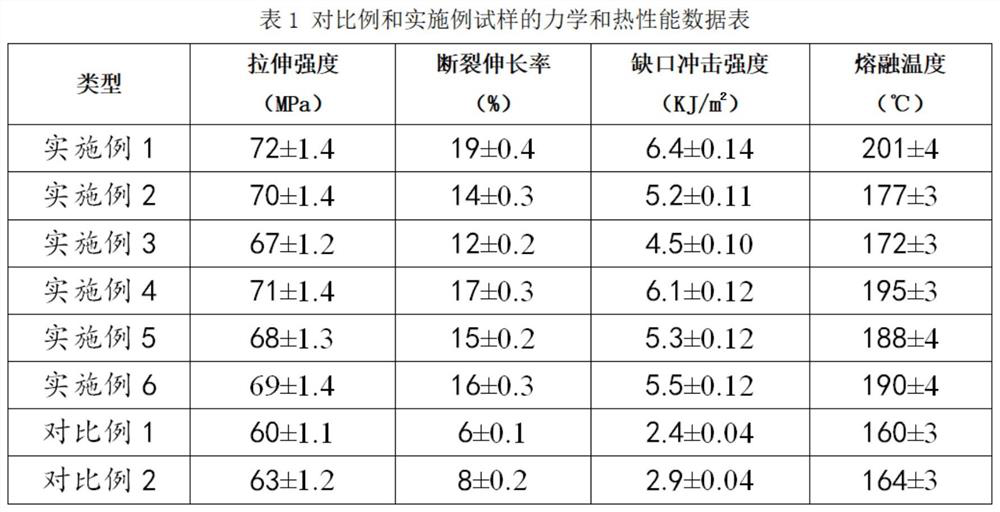

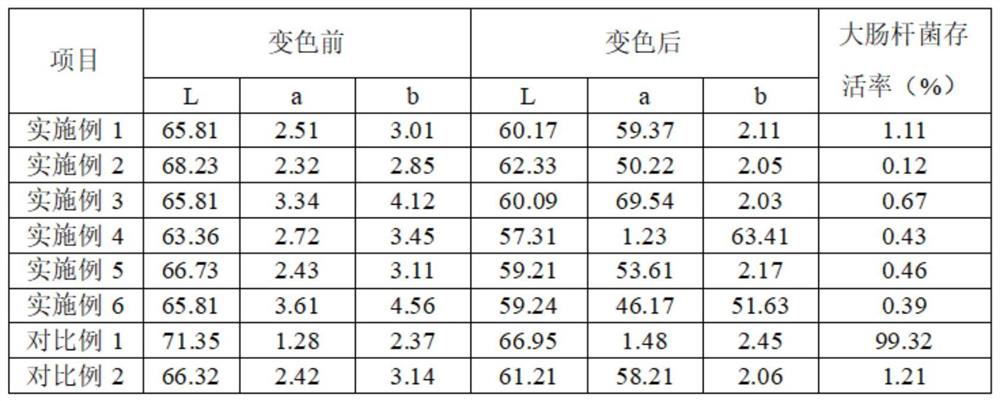

Examples

Embodiment 1

[0036] S1: Mix 55 parts of PLA2002D, 10 parts of cellulose nanocrystals, 2 parts of triallyl isocyanurate, and 10 parts of photosensitive color changing powder MC#12 (colorless to purple, Shenzhen Qianbianse New Material Technology Co., Ltd.) , 3 parts of nano-silver, 0.5 parts of light stabilizer 770, 1.5 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 2 parts of zinc stearate were put into high-speed Stir in the mixer for 8 minutes to obtain the mixture; put it into a twin-screw extruder for melting and blending, and extrude to obtain mixture slices;

[0037]S2: After dry-blending the polylactic acid slices in S1 and 25 parts of polycaprolactone in a high-speed mixer, spin them through a spinneret on a melt spinning machine, and obtain as-spun fibers by drawing, cooling, and winding;

[0038] S3: The primary fibers in S2 are bundled through a bundler, and then melted and formed by pultrusion molding, cooled, and wound to obtain ...

Embodiment 2

[0041] S1: Mix 50 parts of PLA2002D, 10 parts of cellulose nanocrystals, 3 parts of triallyl isocyanurate, and 8 parts of photosensitive color-changing powder MC#12 (colorless to purple, Shenzhen Qianbianse New Material Technology Co., Ltd.) , 5 parts of nano-zinc oxide, 0.4 parts of light stabilizer 770, 1.5 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 2.5 parts of zinc stearate into Stir in a high-speed mixer for 8 minutes to obtain a mixture; put it into a twin-screw extruder for melting and blending, and extrude to obtain mixture slices;

[0042] S2: After dry-blending the polylactic acid slices in S1 and 35 parts of polyhydroxyalkanoate in a high-speed mixer, spin through a spinneret on a melt spinning machine, and obtain as-spun fibers through drafting, cooling, and winding;

[0043] S3: The primary fibers in S2 are bundled by a bundler, and then melted, cooled, and wound by a pultrusion molding process to obtain a 3D pri...

Embodiment 3

[0046] S1: Mix 60 parts of PLA2002D, 12 parts of cellulose nanocrystals, 2.5 parts of triallyl isocyanurate, and 11 parts of photochromic powder MC#12 (colorless to purple, Shenzhen Qianbianse New Material Technology Co., Ltd.) , 3 parts of nano-silver, 0.8 parts of light stabilizer 770, 1.9 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 2.1 parts of zinc stearate were put into high-speed Stir in the mixer for 9 minutes to obtain the mixture; put it into a twin-screw extruder for melting and blending, and extrude to obtain mixture slices;

[0047] S2: After dry-blending the polylactic acid slices in S1 and 15 parts of polyhydroxyalkanoate in a high-speed mixer, spin through a spinneret on a melt spinning machine, and obtain as-spun fibers through drafting, cooling, and winding;

[0048] S3: The primary fibers in S2 are bundled by a bundler, and then melted, cooled, and wound by a pultrusion molding process to obtain a 3D printing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com