Chemical milling solution and chemical milling process suitable for Al-Mg-Sc alloy

A chemical milling and solution technology, applied in the field of aluminum alloy processing, can solve the problem that there is no chemical milling process of Al-Mg-Sc alloy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

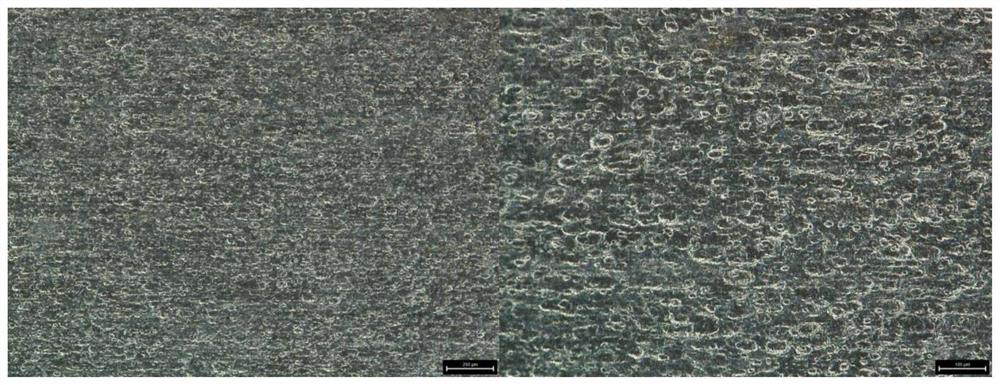

Image

Examples

Embodiment 1

[0035] 1) Configure the milling solution: first add 180g / L sodium hydroxide, stir evenly, add 20g / L aluminum shavings, completely dissolve, stir evenly, and finally add 40g / L triethanolamine and 10g / L sodium sulfide, stir Uniform, water bath heating temperature 90 ℃;

[0036] 2) Hang the Al-Mg-Sc alloy plate test piece with a thickness of H=5.00 mm vertically and immerse it in the chemical milling solution, take it out after chemical milling for 10 minutes, pickle to remove surface corrosion products, blow dry, and measure the thickness h of the test piece after chemical milling =4.36mm, through the thinning thickness of the test piece before and after the corrosion and the milling time, the single-sided milling speed of the Al-Mg-Sc alloy plate in the solution is calculated v=(H-h)÷2÷t=0.032mm / min; the chemical milling speed v is within the range of 0.025-0.035mm / min of the conventional requirement, indicating that the formulation of the chemical milling process is very in l...

Embodiment 2

[0040] 1) Configure the milling solution: first add 200g / L sodium hydroxide, stir evenly, add 30g / L aluminum shavings, after complete dissolution, stir evenly, finally add 40g / L triethanolamine, 10g / L sodium sulfide, stir Uniform, water bath heating temperature 90 ℃;

[0041] 2) Hang the Al-Mg-Sc alloy plate test piece with a thickness of H=5.00 mm vertically and immerse it in the chemical milling solution, take it out after chemical milling for 10 minutes, pickle to remove surface corrosion products, blow dry, and measure the thickness h of the test piece after chemical milling =4.31mm, through the thinning thickness of the test piece before and after the corrosion and the milling time, the single-sided milling speed of the Al-Mg-Sc alloy plate in the solution is calculated v=(H-h)÷2÷t=0.0345mm / min;

[0042] 3) According to the milling speed, calculate the time t=5×1 / 4÷0.0345=36min required to mill the 5.0mm sheet to 1 / 4 thickness;

[0043] 4) According to the calculated t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com