Preparation method of metal oxide two-dimensional material nanosheet with controllable size

A technology of two-dimensional materials and oxides, applied in chemical instruments and methods, titanium oxide/hydroxide, iron compounds, etc., can solve the problem of expensive production of two-dimensional materials, restrictions on the wide application of two-dimensional materials, and the adoption of graphene, etc. problems, to achieve the effect of excellent photochemical properties, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

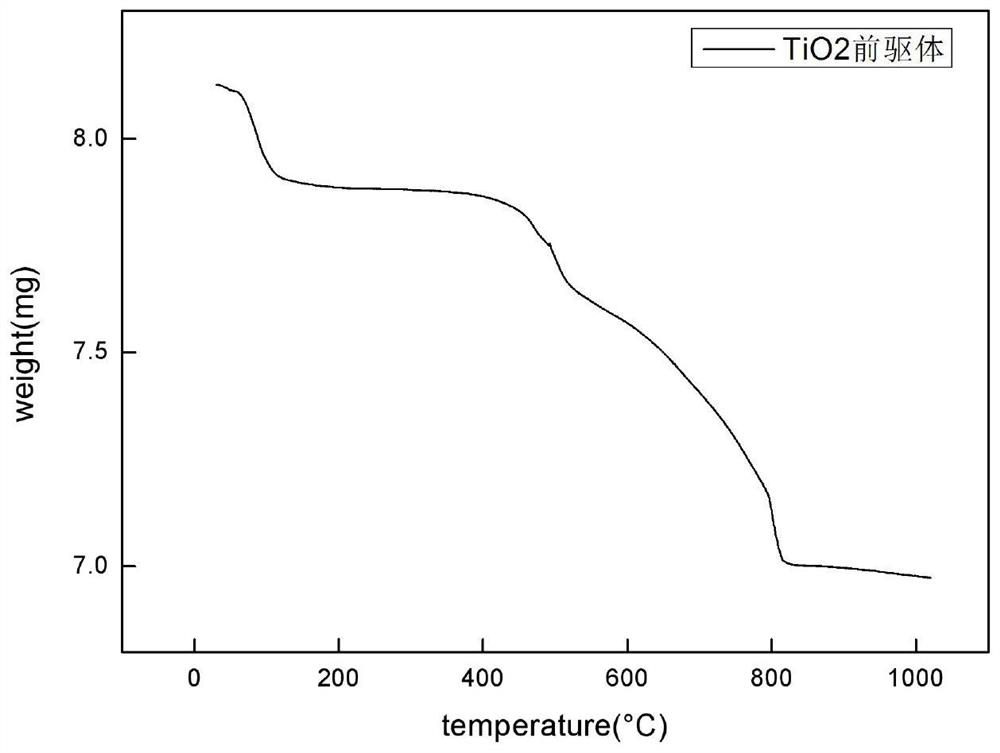

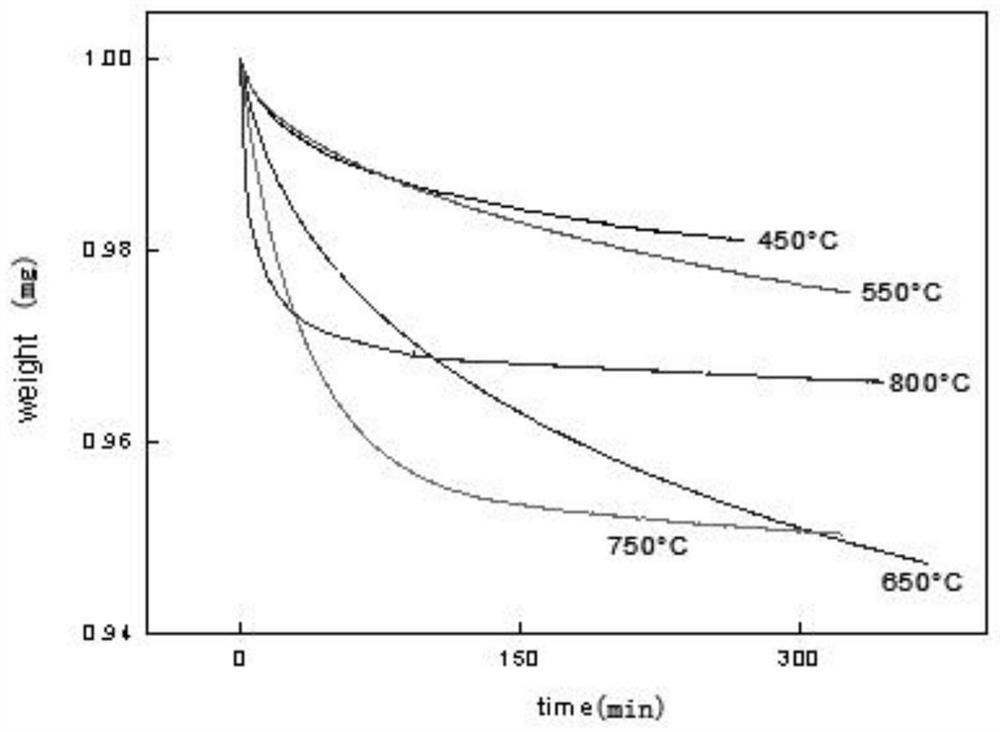

[0046] The ratio of potassium carbonate, lithium carbonate and titanium dioxide is 2.4:0.81:10.36 according to the substance, configure one kilogram of the original mixture (that is, titanium oxide precursor), configure multiple parts, mix them evenly, and take out a small amount of mixture to make the heat of the mixture. Repeat the curve and plan the temperature segment.

[0047] The total thermogravimetric curve of the mixture is figure 1 As shown, the thermogravimetric curves of the mixture at different temperatures are as follows figure 2 shown.

Embodiment 2

[0049] On the basis of embodiment 1, get three parts of one kilogram of original mixture to do three groups of experiments, respectively carry out the following operations:

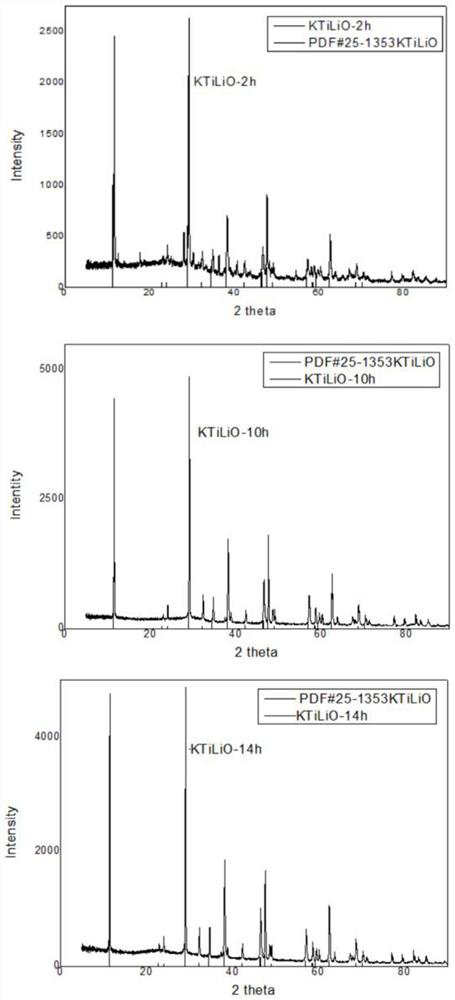

[0050] One kilogram of the original mixture was put into a muffle furnace, heated at 650° C. for 5 hours, taken out and ground after the sintering was completed, and the residual gas in the mixture was exhausted. The mixture was then put into a muffle furnace, heated at 750° C. for 4 hours, taken out and ground after the sintering was completed, and the residual gas in the mixture was exhausted. The temperature was adjusted to 800°C, and the final sintering time of the three groups of mixtures was designed to be 2h, 10h, and 14h, respectively, to obtain the original two-dimensional layered material. After that, it was acidified by adding 500 mL of 1 mol / L hydrochloric acid for 7 days, and a new acid solution was added every replacement day, and the powder was separated by filtration to obtain a protonated...

Embodiment 3

[0055] On the basis of Example 2, the concentration of the solution was designed in the stripping of the organic base, and the volumes of water added were 2L, 4L, and 8L, respectively. Other steps are the same as in Example 2. Finally, two-dimensional materials were successfully prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com