Plant natural component extraction device and extraction process

A technology of natural ingredients and extraction devices, applied in separation methods, filtration separation, grain processing, etc., to achieve the effects of saving extraction costs, accelerating release rates, and high heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

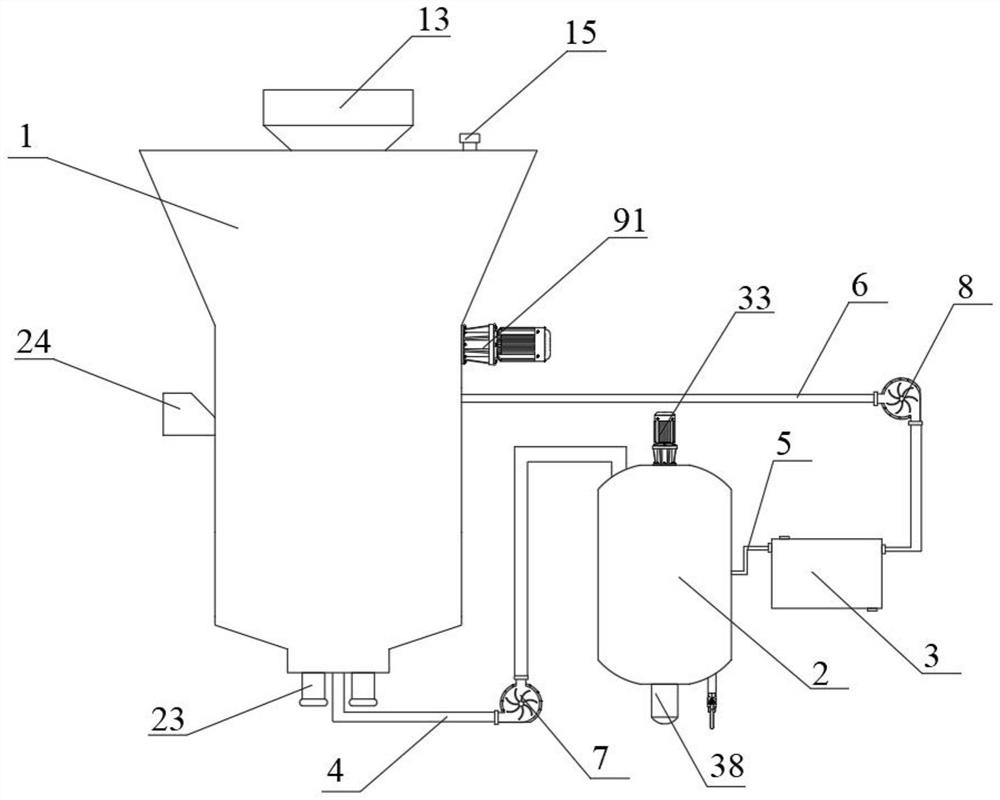

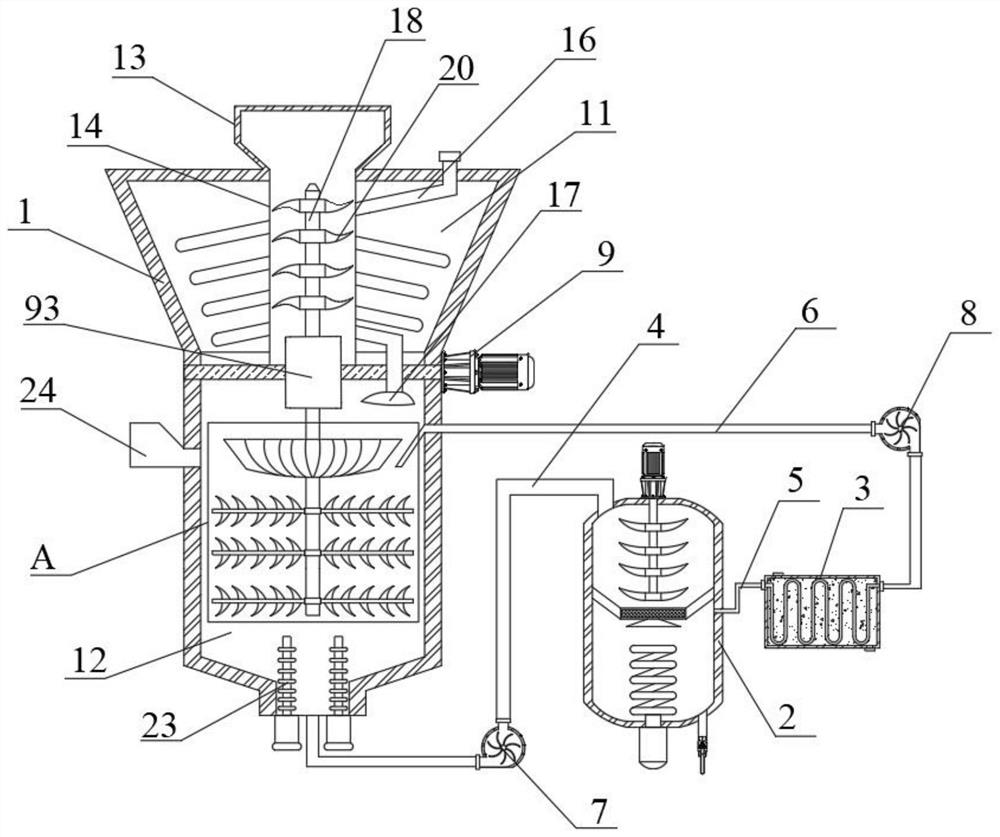

[0039] like figure 1 As shown, this embodiment provides a plant natural component extraction device, including a crushing extraction tank 1, a centrifugal distillation tank 2 and a condensation tank 3, and the bottom of the crushing extraction tank 1 is connected to the top of the centrifugal distillation tank 2 through a first infusion pipe 4. , the side wall of the centrifugal distillation tank 2 is connected to one side of the condensation tank 3 through the gas phase pipe 5 , and the other side of the condensation tank 3 is connected to the side wall of the crushing extraction tank 1 through the second infusion pipe 6 . A first lift pump 7 and a second lift pump 8 are respectively provided on the conveying paths of the first infusion pipe 4 and the second infusion pipe 6 . The crushing and extraction tank 1 is used for preheating and crushing the crushed plant tissue to obtain plant powder, and then the plant powder is subjected to solvent extraction by means of ultrasonic...

Embodiment 2

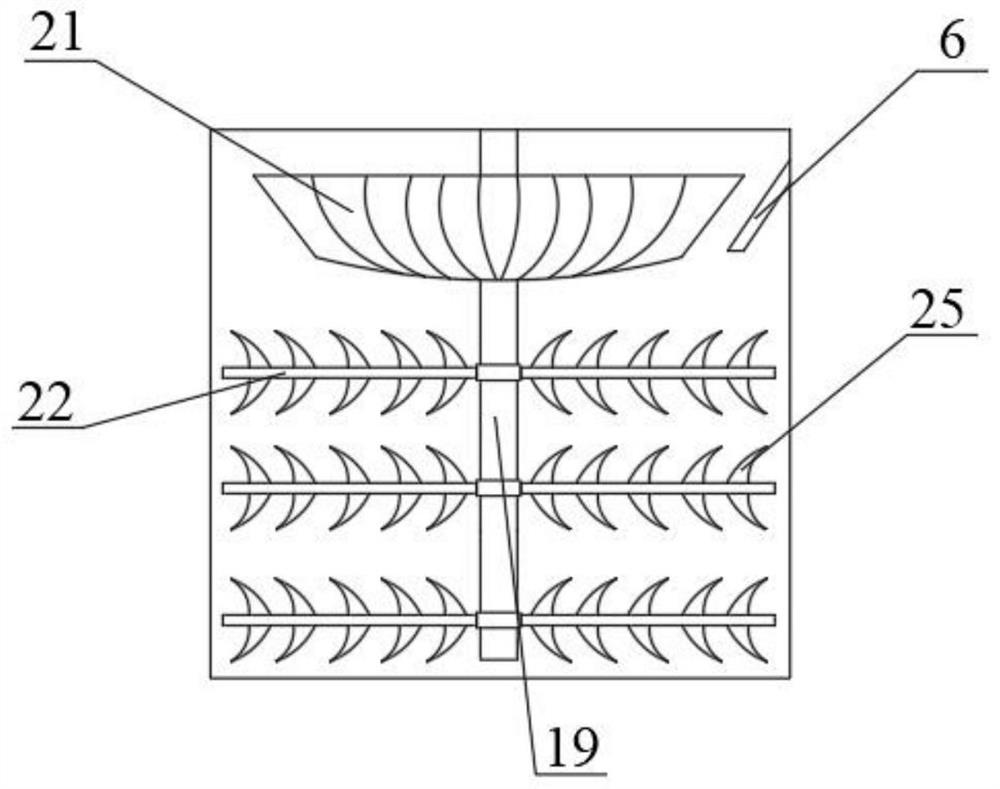

[0047] like image 3 , Figure 5 As shown, the plant natural component extraction device provided in this embodiment is improved on the basis of Embodiment 1, the difference is that: the drainage mechanism 21 includes a drainage plate 26 and a fixed shaft 27, and the main body of the drainage plate 26 is horizontal from top to bottom. The concave cavity 28 is provided on the upper surface of the drainage plate 26 , and the fixed shaft 27 penetrates the axis of the drainage plate 26 and is fixedly connected with the second rotating shaft 19 . The top outer edge of the drainage plate 26 is provided with a through hole 29 communicating with the lower surface thereof. The size of the upper surface of the drainage plate 26 is larger than the cross-sectional size of the crushing channel 14 .

[0048] When the second rotating shaft 19 drives the drainage mechanism 21 and the stirring blade 22 to rotate, the drainage plate 26 of the drainage mechanism 21 has a concave cavity 28, and...

Embodiment 3

[0053] like Figure 1-8 As shown, the present embodiment provides a process for extracting natural plant components, comprising the following steps:

[0054] Step 1, cleaning and pre-grinding: cleaning, drying, and pre-grinding the plant tissue to obtain a plant tissue crushed product with a particle size of 0.2 to 0.6 mm; wherein, the plant tissue is selected from plant seeds, flowers, rhizomes or fruits, and the plants are selected from soybeans, peanuts, Peony, lilac, rosemary, bellflower, etc.;

[0055] Step 2, preheating and pulverizing: the plant tissue pulverized material is passed into the plant natural component extraction device, and the plant powder is obtained by preheating and pulverizing in the preheating pulverizing cavity 11;

[0056] Step 3, solvent extraction: the plant powder enters the ultrasonic extraction chamber 12, adds a solvent, and extracts the extract by the solvent under the action of steam heating and ultrasonic vibration; the solvent is selected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com