Battery pole and battery cover plate assembly

A battery cover and battery pole technology, which is applied to battery components, electrical components, circuits, etc., can solve problems such as reducing the utilization rate of end face area, battery thermal runaway, affecting battery electrical performance and safety performance, etc., to improve the structure Strength and service life, no disconnection at the joint surface, and low risk of structural failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

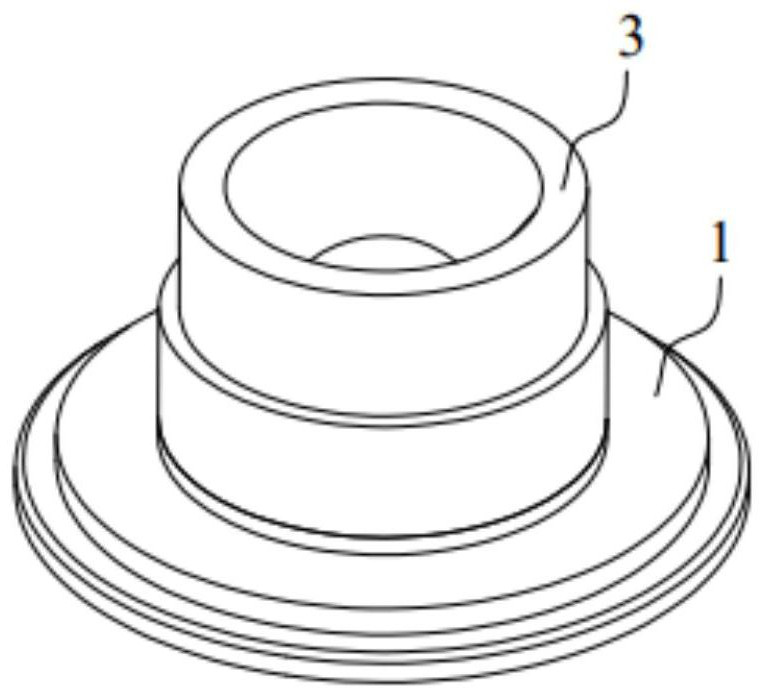

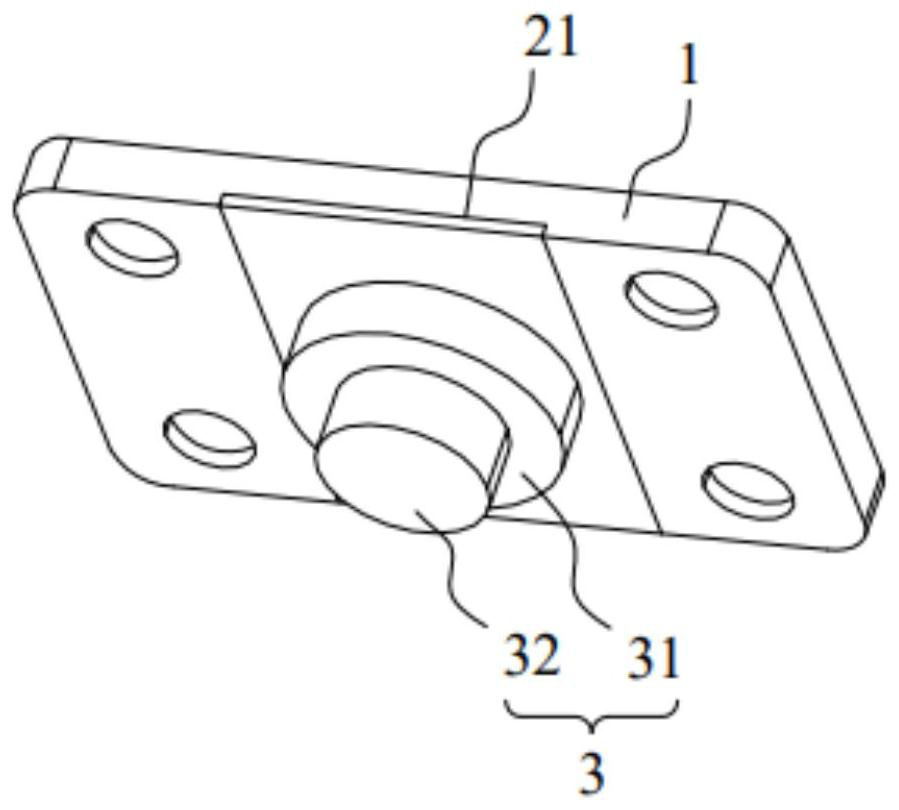

[0037] like figure 2 As shown, this embodiment provides a battery pole, including a substrate 1 and a connecting column 3, the substrate 1 is made of an aluminum plate 2, the substrate 1 is placed outside the battery, and is used to connect with an external circuit of the battery; the connecting column 3 is made of The copper plate 4 is made, one end of the connecting column 3 is fixedly connected with the base plate 1, and the other end is used for connecting with the internal cells of the battery. The battery pole structure in the present invention is completely opposite to the battery pole structure in the prior art. The surface of the substrate 1, which is the terminal surface of the battery pole, is an integral plane. The battery pole and the battery external circuit are welded by welding. When connecting, while keeping the welding area of the substrate 1 unchanged, the overall area of the substrate 1 is smaller, which saves the space of the battery pack; The substr...

Embodiment 2

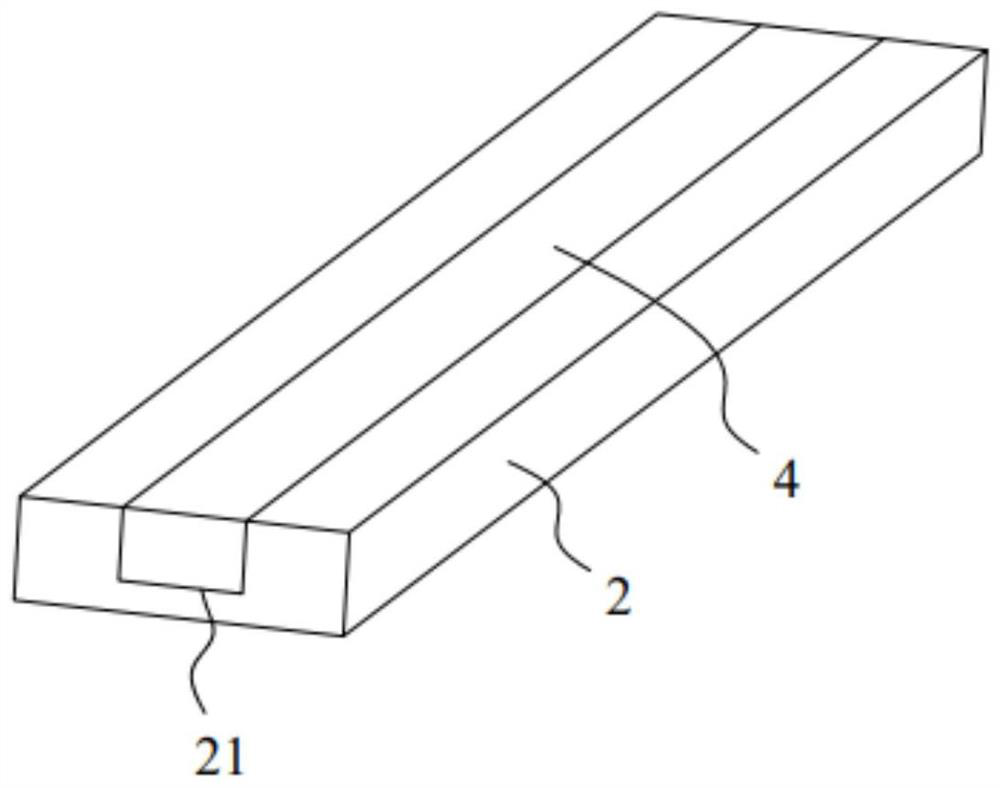

[0050] like Figure 7 As shown, the difference from the first embodiment is that when the battery pole is produced, when the copper-aluminum composite plate is hot-rolled, a through groove 21 is opened on the surface of the aluminum plate 2, and the width of the through groove 21 is equal to the width of the copper plate 4. However, the depth of the through slot 21 is less than the thickness of the copper plate 4, so that after the copper plate 4 is placed in the through slot 21, the surface of the copper plate 4 protrudes from the surface of the aluminum plate 2, and then the copper plate 4 and the aluminum plate 2 are subjected to hot rolling treatment, although some difficulties in hot pressing are increased. However, only a small part of the copper plate 4 is embedded in the aluminum plate 2, which further reduces the consumables of copper and aluminum, and further improves the utilization rate of materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com