High-partial-discharge insulating material for oil-cooled motor of new energy automobile and preparation method of high-partial-discharge insulating material

A technology for new energy vehicles and insulating materials, applied in the direction of inorganic insulators, organic insulators, insulators, etc., can solve the problems of high partial discharge performance, poor insulation performance, poor safety, etc., achieve high partial discharge performance and improve partial discharge performance , the effect of high insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

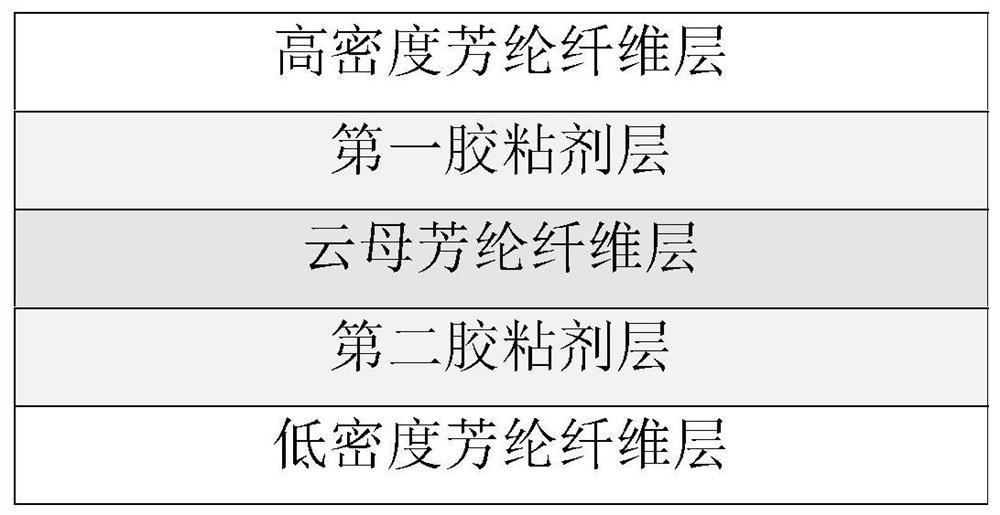

Method used

Image

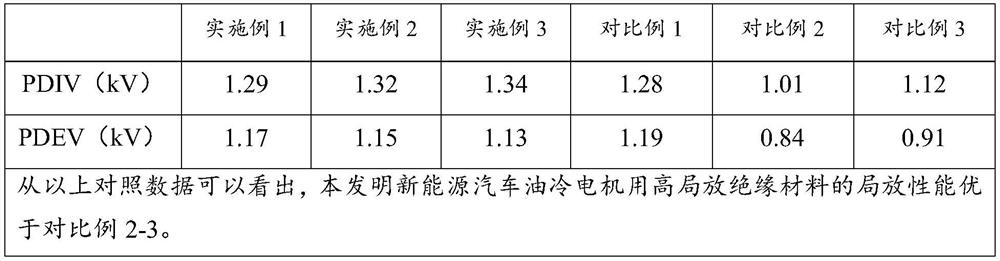

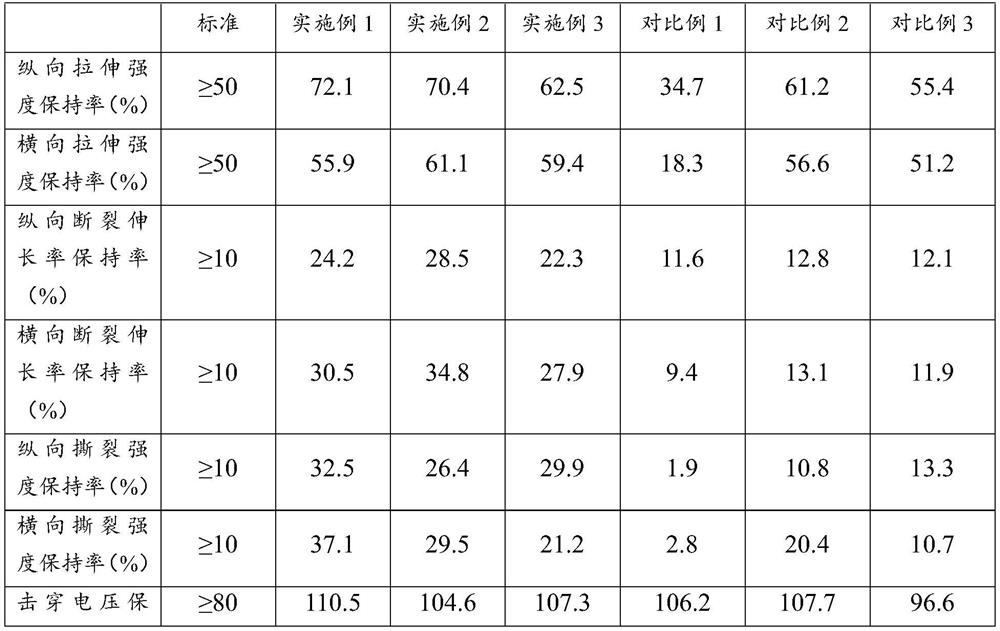

Examples

Embodiment 1

[0040] (a) 4-hydroxybutyl acrylate is dissolved in acetone to form a solution of 50% by mass;

[0041] (b) dissolving polyol trimethylolpropane (TMP) with acetone to form a solution of 40% by mass;

[0042] (c) using ethyl acetate solvent to dissolve toluene diisocyanate to form a solution of 70% mass ratio;

[0043] (d) stirring the gained 4-hydroxybutyl acrylate solution, polyol solution and toluene diisocyanate solution according to the mass ratio of 10:1:2 to obtain acrylic modified adhesive glue;

[0044] (e) High density at 0.18mm (0.96g / cm 3 ) The surface of the aramid fiber paper is all coated with the glue solution of the obtained acrylic modified adhesive, and the coating amount is 20g / m 2 ;

[0045] (f) drying the high-density aramid fiber paper substrate with the adhesive glue through a drying tunnel to remove the solvent in the modified adhesive glue to obtain a high-density aramid fiber with the acrylic modified adhesive fiber paper;

[0046] (g) laminating ...

Embodiment 2

[0051] (a) 4-hydroxybutyl acrylate is dissolved in ethyl acetate to form a solution of 50% by mass;

[0052] (b) dissolving polyol trimethylolpropane (TMP) with ethyl acetate to form a solution of 50% by mass;

[0053] (c) using methyl acetate solvent to dissolve biuret polyisocyanate to form a solution of 75% mass ratio;

[0054] (d) stirring the obtained 4-hydroxybutyl acrylate solution, polyol solution and biuret polyisocyanate solution uniformly according to the mass ratio of 20:4:5 to obtain acrylic modified adhesive glue;

[0055] (e) High density at 0.13mm (0.96g / cm 3 ) The surface of the aramid fiber paper is all coated with the glue solution of the obtained acrylic modified adhesive, and the coating amount is 18g / m 2 ;

[0056] (f) drying the high-density aramid fiber paper substrate with the adhesive glue through a drying tunnel to remove the solvent in the modified adhesive glue to obtain a high-density aramid fiber with the acrylic modified adhesive fiber paper...

Embodiment 3

[0062] (a) 4-hydroxybenzoyl acrylate is dissolved in ethyl acetate to form a solution of 35% by mass;

[0063] (b) dissolving polyol dipropylene glycol (IPG) using ethyl acetate to form a solution of 40% by mass;

[0064] (c) using acetone to dissolve polymethylene polyphenylene isocyanate to form a solution of 60% by mass;

[0065] (d) stirring the gained 4-hydroxybenzoyl acrylic acid solution, polyol solution and biuret polyisocyanate solution according to the mass ratio of 15:2:4 to obtain acrylic modified adhesive glue;

[0066] (e) High density at 0.18mm (1.02g / cm 3 ) The surface of the aramid fiber paper is all coated with the glue solution of the obtained acrylic modified adhesive, and the coating amount is 22g / m 2 ;

[0067] (f) drying the high-density aramid fiber paper substrate with the adhesive glue through a drying tunnel to remove the solvent in the modified adhesive glue to obtain a high-density aramid fiber with the acrylic modified adhesive fiber paper;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com