Antibacterial fiber, wet and dry antibacterial non-woven fabric and preparation method

A technology of antibacterial fibers and composite fibers, applied in the field of dry and wet antibacterial non-woven fabrics and their preparation, and the field of antibacterial fibers, can solve the problem of low stability of disinfection effect and achieve good water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

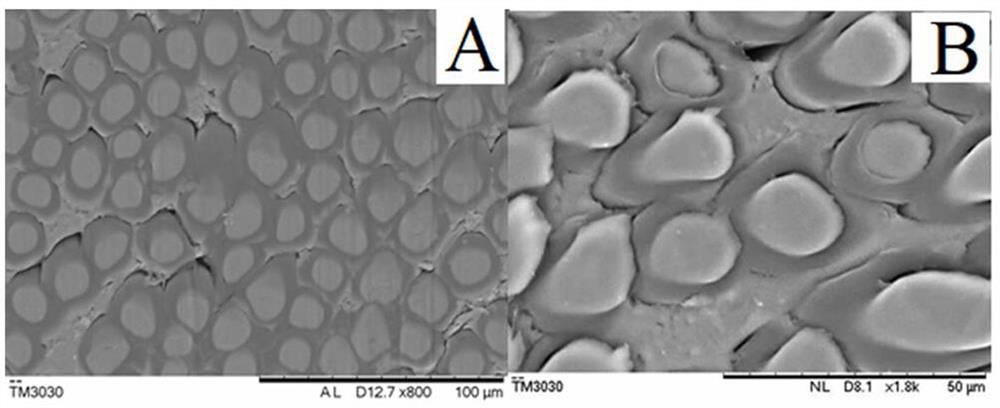

Image

Examples

Embodiment 1

[0027] 1. Preparation of hydroxyl-containing nano-ZnO

[0028] The commercially available zinc oxide with a particle size of 20-30 nm is mixed and ground with polyvinylpyrrolidone, polyethylene glycol, and glycerol in a mass ratio of 1:0.1:0.5:0.1 to prepare hydroxyl-containing nano-zinc oxide.

[0029] 2. Preparation of ES skin-core composite fibers

[0030] The modified PE material was prepared by adding 0.03% of the hydroxyl-containing nano-zinc oxide into the PE material in the slice modification device. As the subsequent skin layer, 0.03% of the hydroxyl-containing nano-zinc oxide was added to the slice modification device. The modified PET material is obtained by adding it to the PET material, which is used as the subsequent core layer; in the composite fiber preparation device, the above-mentioned skin layer and core layer materials are respectively added to the spinning melt pipe at a mass ratio of 1:1. Twin-screw extrusion, and then ejected through a composite spinne...

Embodiment 2

[0033] The ES skin-core composite fiber prepared in Example 1 was prepared by the hot-air non-woven fabric processing technology to obtain ES hot-air non-woven fabric.

[0034] Take the hot air non-woven fabric and soak it in deionized water at a mass ratio of 1:30 for 24 hours. After testing, there are no other chemical substances in the water. At the same time, the water also has an efficient antibacterial effect.

[0035] The antibacterial effects of the non-woven samples prepared in this example and the water after soaking were tested, and the results are shown in Table 1.

[0036] Table 1:

[0037] .

[0038] After the ES composite fiber non-woven fabric provided in this example is soaked in deionized water, the results of the metal dissolution test in the soaking water are shown in Table 2.

[0039] Table 2:

[0040] .

[0041] The test results in Table 1 show that the antibacterial rate of Staphylococcus aureus is 99%, the antibacterial rate of Escherichia coli ...

Embodiment 3

[0046] First prepare hydroxyl-containing nano-copper oxide, mix and grind commercially available 20-30 nm copper oxide with polyvinylpyrrolidone, polyethylene glycol, and glycerol in a mass ratio of 1:0.1:0.4:0.2 to prepare hydroxyl-containing Nano copper oxide.

[0047] 0.03% nanometer copper oxide is added to PE material in the slice modification device to obtain the skin layer PE material, and 0.03% nanometer zinc oxide is added to the PET material in the slice modification device to obtain the modified PET core layer material; In the preparation of composite fibers, the above-mentioned skin layer and core layer materials are respectively added into the spinning melt pipe, extruded through twin-screw, and then ejected through the composite spinneret assembly, cooled, formed, wound, stretched, crimped and shaped, and finally ES was obtained. Skin-core composite fiber, ES hot-rolled non-woven fabric was prepared by hot-rolled non-woven fabric processing technology. The test r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com