Flow pattern regulator for water-based drilling fluid and preparation method of flow pattern regulator

A technology of water-based drilling fluid and flow regulator, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of unusability and insufficient temperature resistance, and achieve the effect of adjusting rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

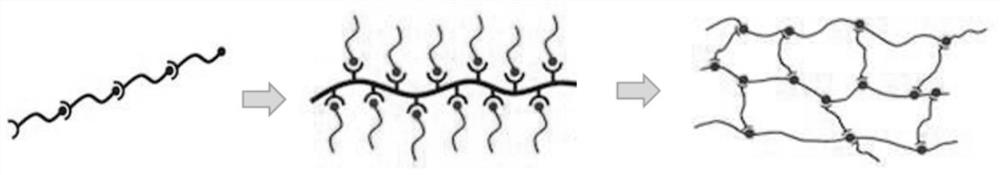

Method used

Image

Examples

preparation example Construction

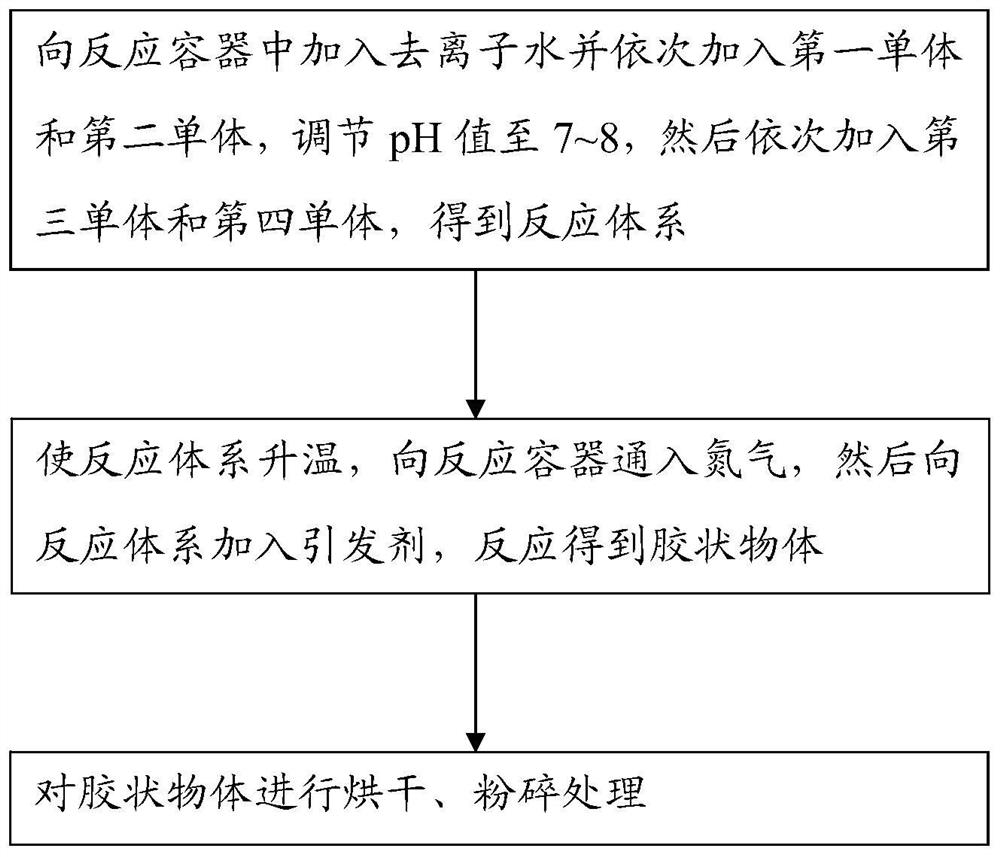

[0045] The present invention also provides a method for preparing a flow-pattern regulator for water-based drilling fluid, such as figure 2 As shown, the preparation method includes:

[0046] (1) Add deionized water into the reaction vessel, add the first monomer and the second monomer in sequence, adjust the pH value to 7-8, and then add the third monomer and the fourth monomer in sequence to obtain a reaction system.

[0047] First, prepare the first monomer, the second monomer, the third monomer and the fourth monomer in proportion. Add the first monomer and deionized water to the reaction vessel, stir to dissolve the first monomer, then add the second monomer to the reaction vessel, and adjust the pH value of the solution to neutral (that is, the pH value is 7 to 8). Then add the third monomer and the fourth monomer in sequence, and stir until dissolved. Supplement deionized water to the reaction vessel, so that the sum of the first monomer, the second monomer, the thi...

Embodiment 1

[0056] First, take a three-necked flask, dissolve the monomer acrylamide AM (10.5 g) in 162 g of distilled water, add acrylic acid AA (25 g), and stir and mix for later use. Weigh 8.1g of sodium hydroxide and dissolve it in 30g of water, add the alkali solution to the above-mentioned acrylamide and acrylic acid solution, adjust the pH of the solution to 7-8, and continue to add N-vinylpyrrolidone (14.2g) to the solution, 11 After sodium carbenoate (1.6 g) was stirred for 5 min, the solution was heated to 40° C. and nitrogen gas was introduced to remove dissolved oxygen in the solution. Keep the nitrogen flow for 30min, dissolve azobisisobutylimidazoline hydrochloride in distilled water to make a solution with a mass concentration of 5%, after the nitrogen flow time reaches 30min, add the above 5% azobisisobutylimidazoline 2 g of the hydrochloride solution was kept at 40° C. for 6 hours, and then the obtained colloid was dried to obtain a temperature-resistant and salt-resistan...

Embodiment 2

[0058] First, take a three-necked flask and dissolve the monomer acrylamide AM (2.5g) in 100g of distilled water, add 2-acrylamido-2-methylpropanesulfonate sodium AMPS-Na (13.5g), stir and mix for later use, adjust The pH of the solution is 7 to 8. Continue to add N-vinylpyrrolidone (3.5 g) to the solution. After stirring for 5 min with undecylenamide (0.5 g), the solution is heated to 40° C. and nitrogen is introduced to remove the solution. dissolved oxygen. Keep the nitrogen flow for 30min, dissolve azobisisobutylimidazoline hydrochloride in distilled water to make a 5% solution, after the nitrogen flow time reaches 30min, add the above 5% azobisisobutylimidazoline hydrochloride The solution was 0.7 g, and the temperature was kept at 40° C. for 10 h, and then the obtained colloid was dried to obtain a temperature-resistant and salt-resistant polymer.

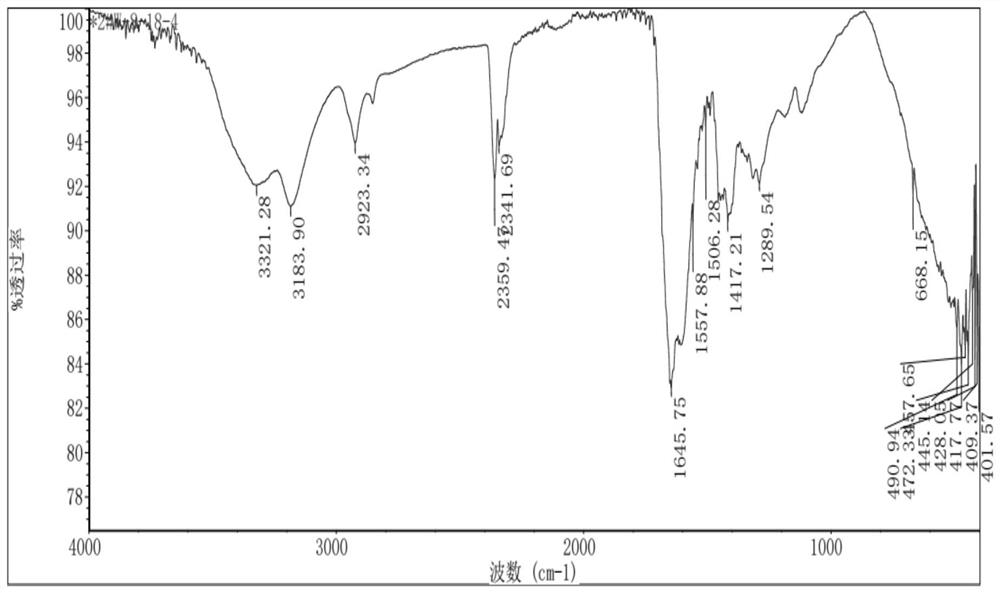

[0059] image 3 It is the infrared spectrum of the temperature-resistant and salt-resistant polymer prepared in this exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com