High-strength concrete taking carbon chromium slag as main aggregate, processing device and preparation process of high-strength concrete

A high-strength concrete and processing device technology, applied in the field of concrete, can solve the problems of difficulty in meeting the use requirements of high-strength scenarios, poor surface hardness and wear resistance, and low strength of sand and gravel aggregates, and achieve high toughness, improved strength, and material residues. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

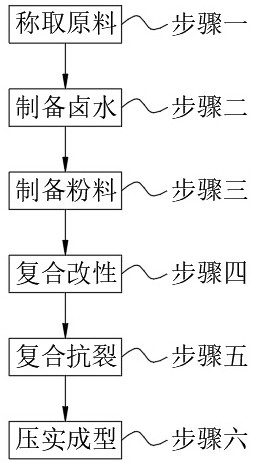

Method used

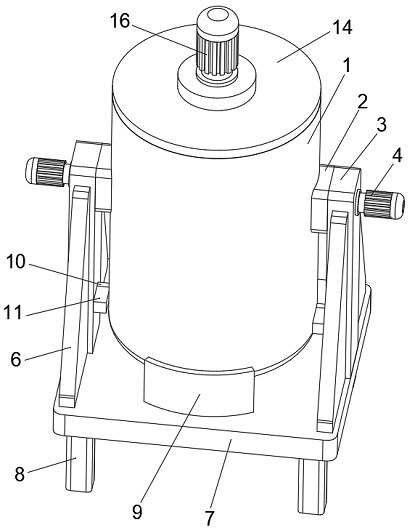

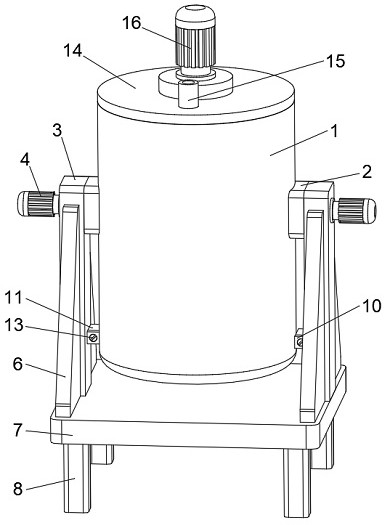

Image

Examples

Embodiment 1

[0026]High-strength concrete with carbon-chromium slag as the main aggregate, the formula includes: high-strength aggregate, magnesium chloride solution, defoamer, light-burned magnesium oxide, fly ash, deionized water, compound modifier, polypropylene fiber powder, Zinc maleate, acrylamide and dibenzoyl peroxide, the parts by weight of each component are: 750 parts of high-strength aggregate, 60 parts of magnesium chloride solution, 3 parts of defoamer, 150 parts of light Burnt magnesium oxide, 20 parts fly ash, 300 parts deionized water, 1 part composite modifier, 80 parts polypropylene fiber powder, 15 parts zinc maleate, 5 parts acrylamide and 1 part The high-strength aggregate is composed of carbon-chromium slag coarse material and nickel-iron slag fine material with a weight ratio of 6:1 mixed, and the particle size of the carbon-chromium slag coarse material is 10mm, and the nickel-iron slag is The particle size of the fine material is 0.85mm; the mass fraction of the m...

Embodiment 2

[0029] High-strength concrete with carbon-chromium slag as the main aggregate, the formula includes: high-strength aggregate, magnesium chloride solution, defoamer, light-burned magnesium oxide, fly ash, deionized water, compound modifier, polypropylene fiber powder, Zinc maleate, acrylamide and dibenzoyl peroxide, the parts by weight of each component are: 760 parts of high-strength aggregate, 61 parts of magnesium chloride solution, 3 parts of defoamer, 158 parts of light Burnt magnesium oxide, 22 parts fly ash, 340 parts deionized water, 1 part composite modifier, 81 parts polypropylene fiber powder, 15 parts zinc maleate, 5 parts acrylamide and 1 part The high-strength aggregate is composed of carbon-chromium slag coarse material and nickel-iron slag fine material with a weight ratio of 6:1 mixed, and the particle size of the carbon-chromium slag coarse material is 10mm, and the nickel-iron slag is The particle size of the fine material is 0.85mm; the mass fraction of the ...

Embodiment 3

[0032] High-strength concrete with carbon-chromium slag as the main aggregate, the formula includes: high-strength aggregate, magnesium chloride solution, defoamer, light-burned magnesium oxide, fly ash, deionized water, compound modifier, polypropylene fiber powder, Zinc maleate, acrylamide and dibenzoyl peroxide, the parts by weight of each component are: 780 parts of high-strength aggregate, 63 parts of magnesium chloride solution, 3 parts of defoamer, 163 parts of light Burnt magnesium oxide, 24 parts fly ash, 370 parts deionized water, 1 part compound modifier, 84 parts polypropylene fiber powder, 16 parts zinc maleate, 5 parts acrylamide and 1 part The high-strength aggregate is composed of carbon-chromium slag coarse material and nickel-iron slag fine material with a weight ratio of 6:1 mixed, and the particle size of the carbon-chromium slag coarse material is 10mm, and the nickel-iron slag is The particle size of the fine material is 0.85mm; the mass fraction of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com