Polishing equipment for leveling aluminum alloy surface of cylinder

An aluminum alloy surface and aluminum alloy technology, which is applied in the field of aluminum alloy processing, can solve the problems of time-consuming, low grinding efficiency, and poor grinding effect, and achieve the effects of reducing dust content, improving grinding effect, and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

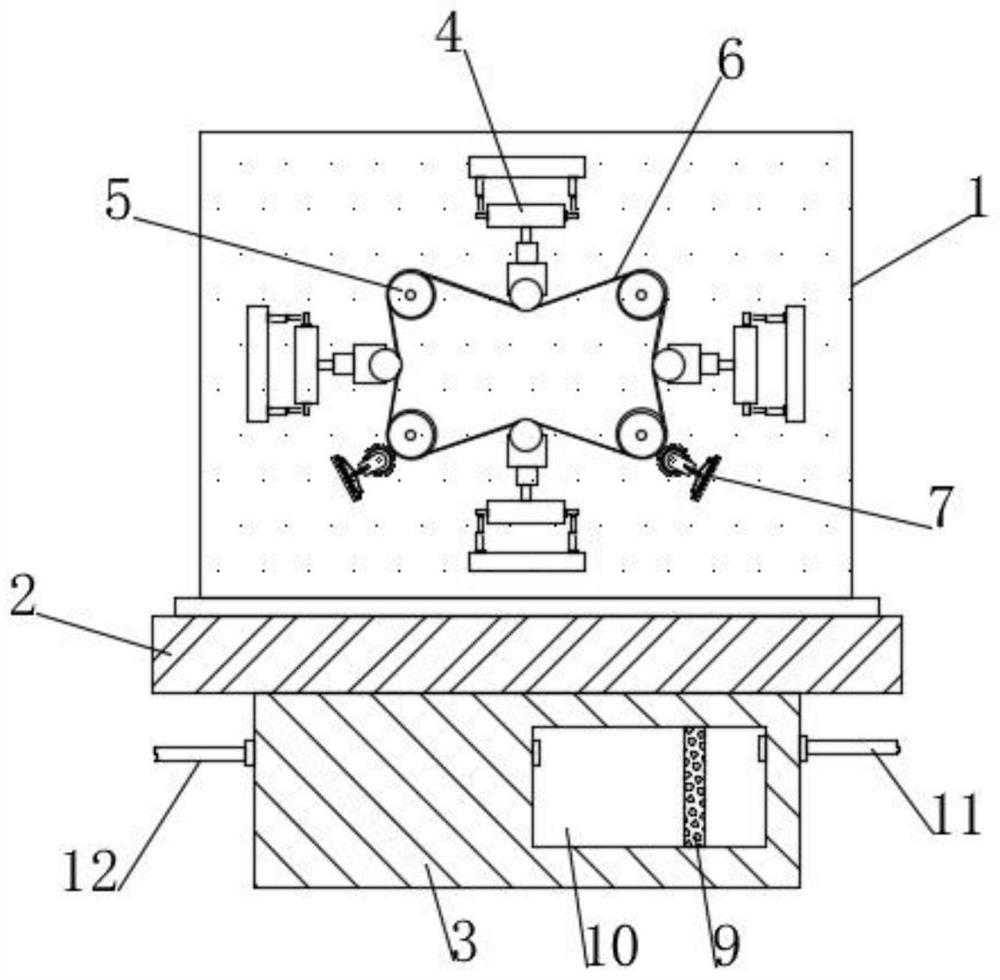

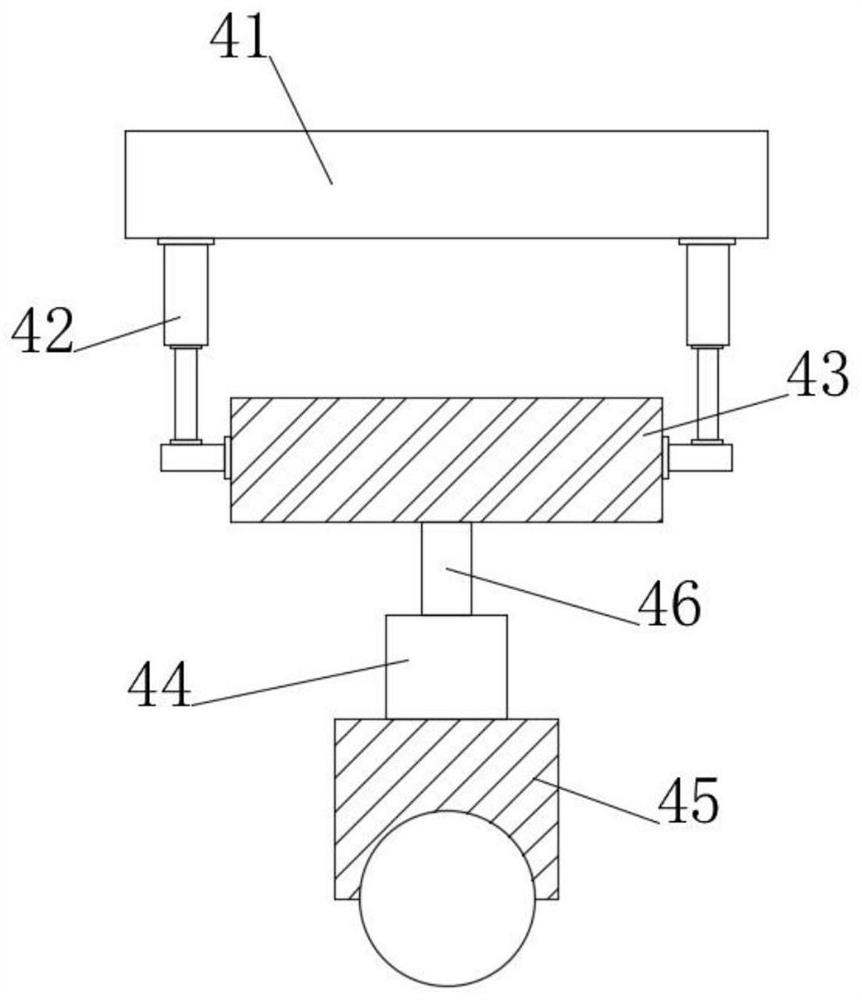

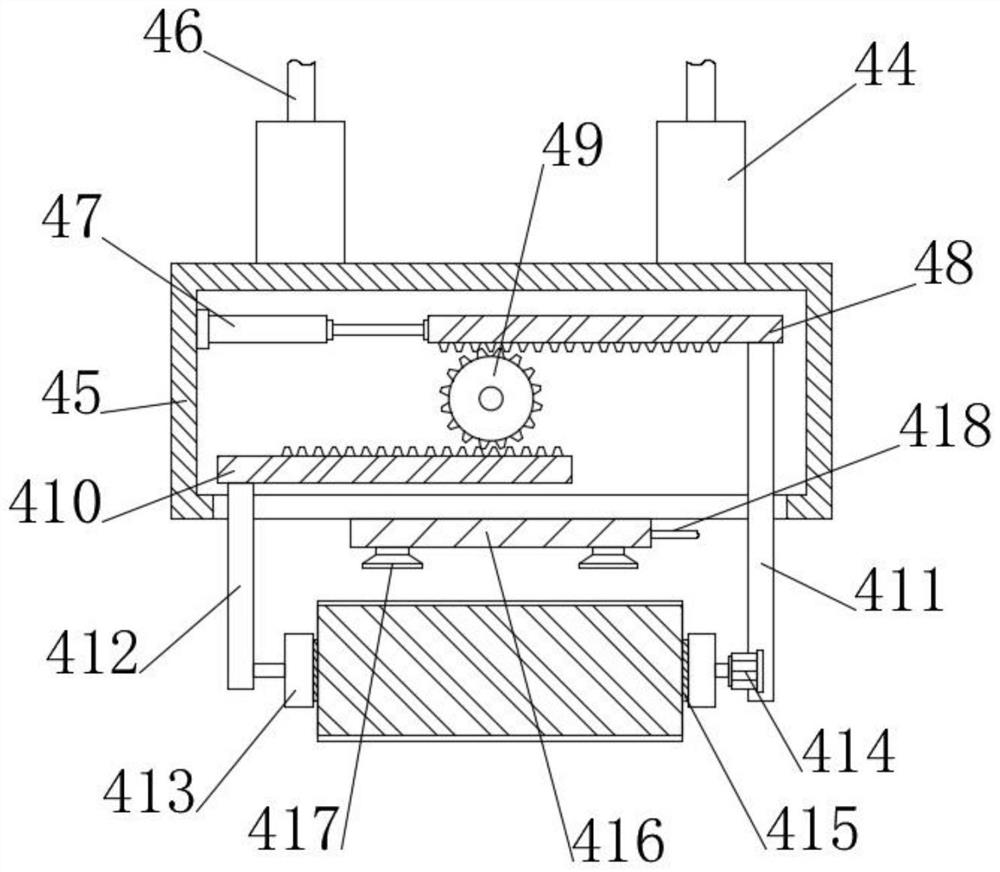

[0044] like Figure 1-5 As shown, the present invention proposes a grinding device for leveling the aluminum alloy surface of a cylinder, including a mounting plate 1 and a fixing plate 2. The fixing plate 2 is arranged horizontally and is fixedly installed on the top of the pressure-bearing seat 3 by bolts. The plate 1 is fixedly installed on the fixed plate 2 by bolts, four sets of driving rollers 5 are installed on the installation plate 1, the grinding motor 8 is fixedly installed on the mounting plate 1 through the motor seat, and the output end of the grinding motor 8 is connected to the corresponding driving roller. 5 is connected, the grinding motor 8 drives the driving roller 5 connected to it, and the four groups of driving rollers 5 are connected by the detachable grinding belt 6, and the area enclosed by the detachable grinding belt 6 is in the shape of a "mouth". The detachable grinding belt 6 is moved under the action of figure 1 For reference), and the rotating...

Embodiment 2

[0050] During the grinding process of the above-mentioned embodiment, when the grinding surface of the detachable grinding belt 6 is continuously used, a large amount of residues will remain in the grinding surface, and a large amount of aluminum alloy residues in the grinding surface will easily lead to the subsequent grinding process. Aluminum alloy is not conducive to continuous guarantee of grinding effect, such as figure 1 and Figure 6-7 As shown, the difference between this embodiment and Embodiment 1 is that the mounting plate 1 is also provided with a surface slag removal component 7, preferably, the number of the surface slag removal component 7 is two groups, and the surface slag removal component 7 It is located on both sides of the lower rotating positioning assembly 4. Specifically, the belt surface slag removal assembly 7 includes a slag removal connecting plate 71 and a side seat 73. The slag removal connecting plate 71 is fixed on the mounting plate 1 by bolts...

Embodiment 3

[0054] The above-mentioned embodiment will generate a large amount of dust during the use process (including the grinding operation and the slag removal operation), and the dust will be scattered into the nearby air, which not only causes pollution to the nearby operating environment, but also brings harm to the health of operators, such as figure 1 and image 3 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the side of the cylinder clamping seat 45 facing the detachable sanding belt 6 is fixedly installed with a dust collecting box 416 by bolts, and the dust collecting The dust box 416 is provided with a dust suction head 417 and a connecting branch pipe 418. During the grinding process, the dust suction head 417 is facing the grinding area, and the dust suction head 417 sucks the dust generated during the grinding process into the dust extraction and dust collecting box 416. It can significantly reduce the dust content in the opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com