Process for surfacing copper alloy on inner surface of 27SiMn stand column of coal mine liquid support

An inner surface and coal mine technology is applied in the field of surfacing copper alloy on the inner surface of a 27SiMn column of a coal mine liquid support, which can solve problems such as affecting physical health, affecting service life, high environmental pollution, etc. The effect of low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

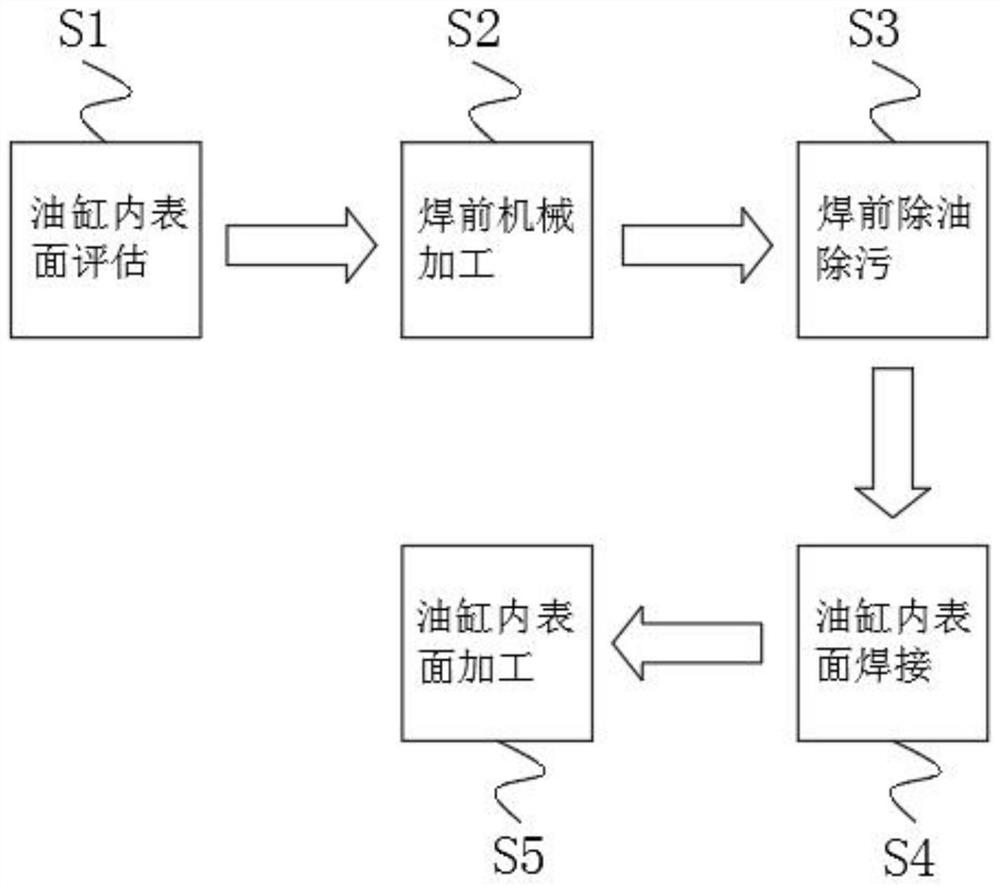

[0021] S1. Evaluation of the inner surface of the oil cylinder: focus on checking whether the oil cylinder has the phenomenon of cylinder expansion, and discard the oil cylinder with the phenomenon of cylinder expansion;

[0022] S2. Machining before welding: first remove the valve seat and other accessories on the outer surface of the cylinder, then check the inner surface of the cylinder, perform local grinding and welding repair for local corrosion, and further weld the process ring at the end of the cylinder, and use the cylinder The mouth is the benchmark machining process ring as the reserved benchmark for post-welding machining, machining the shelf position on the outer surface of the cylinder, further turning the stop, static seal and chamfering of the cylinder body, and finally machining the inner surface of the cylinder with a boring machine;

[0023] S3. Degreasing and decontamination before welding: For cylinders with a diameter larger than 250mm, use a special lase...

Embodiment 2

[0032] S1. Evaluation of the inner surface of the oil cylinder: focus on checking whether the oil cylinder has the phenomenon of cylinder expansion, and discard the oil cylinder with the phenomenon of cylinder expansion;

[0033] S2. Machining before welding: first remove the valve seat and other accessories on the outer surface of the cylinder, then check the inner surface of the cylinder, perform local grinding and welding repair for local corrosion, and further weld the process ring at the end of the cylinder, and use the cylinder The mouth is the benchmark machining process ring as the reserved benchmark for post-welding machining, machining the shelf position on the outer surface of the cylinder, further turning the stop, static seal and chamfering of the cylinder body, and finally machining the inner surface of the cylinder with a boring machine;

[0034] S3. Degreasing and decontamination before welding: For cylinders with a diameter larger than 250mm, use a special lase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com