Preparation method of lithium ion imprinted composite nanofiber membrane based on MOFs (Metal-Organic Frameworks)

A technology of composite nanofibers and nanofiber membranes, which is applied in the field of MOFs and ion imprinting technology, can solve the problems of inability to achieve high-selectivity removal of target pollutants, large environmental impact, poor adsorption effect, etc., and achieve multiple recognition sites and high The effect of selectivity, easy pore structure, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

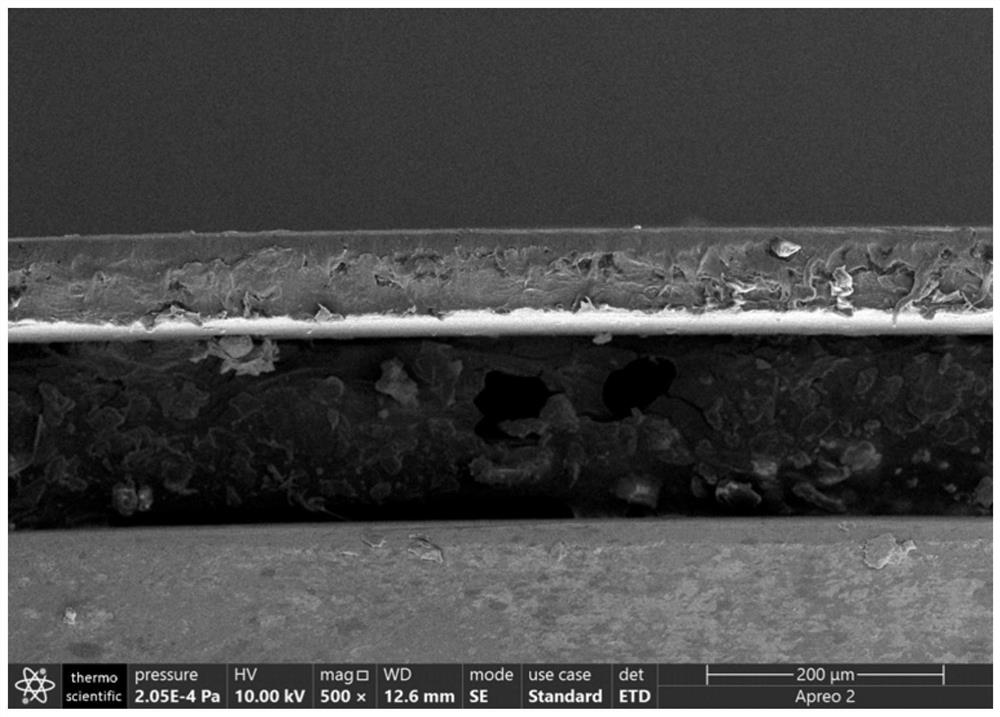

[0030] Embodiment 1: In this embodiment, a method for preparing a lithium ion imprinted composite nanofiber membrane based on MOFs is developed, and a highly selective Li with enhanced hydrophilicity and stability is developed. + Imprinted polymers (MOFs-LiIIPs). with high selectivity for Li + The imprinted polymer was used as the imprinted layer to prepare a new composite material; 12-crown-4 (12C4) was used as the adsorption unit to form a selective Li + Identify sites and prepare films by electrospinning techniques. It includes the following steps:

[0031] 1. Preparation of highly selective Li + Imprinted polymers:

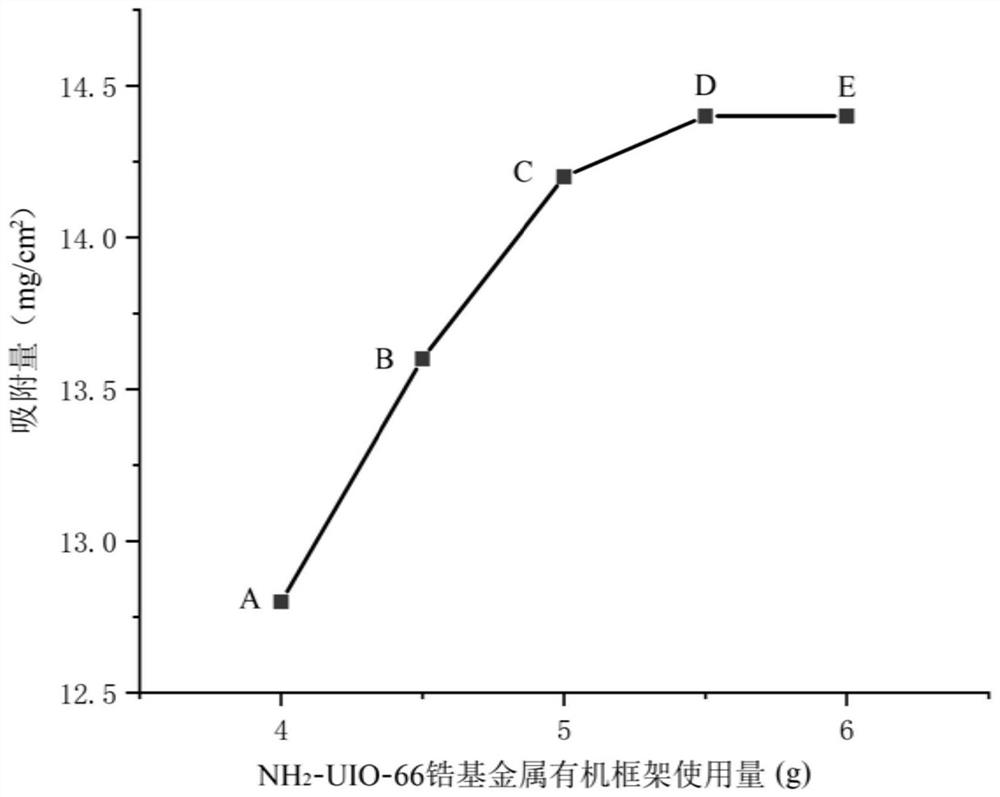

[0032] ①. Mix LiCl, 12-crown ether-4 and anhydrous methanol, then put them into a constant temperature heating magnetic stirrer for pre-polymerization, and then add NH 2 - The UIO-66 zirconium-based organometallic framework is shaken, then α-methacrylic acid and azobisisobutyl cyanide are added, and then shaken under the conditions of nitrogen atmosphere,...

specific Embodiment approach 2

[0040] Embodiment 2: The difference between this embodiment and Embodiment 1 is: the NH described in step 1 2 -UIO-66 zirconium-based organometallic framework was prepared as follows: First, 1 mmol of ZrCl was dissolved in 50 mL of DMF 4 and 1 mmol of 2-aminoterephthalic acid, stirred at room temperature for 0.5 h to obtain a mixed solution; then poured the mixed solution into a polytetrafluoroethylene hydrothermal kettle, and reacted at 120 ° C for 24 h, the resulting suspension ; After cooling and centrifugation, solid matter is obtained, and the solid matter is washed with absolute ethanol and deionized water respectively, and finally, yellow powder is obtained through drying and grinding, which is NH 2 -UIO-66 zirconium based organometallic framework. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0041] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the mass ratio of LiCl described in step 1 ① to the volume ratio of anhydrous methanol is 0.3g:100mL; step 1 described in step 1 ① The volume ratio of 12-crown-4 to anhydrous methanol was 0.3:100. Other steps are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com