Composite 3D printing ink and application thereof

A 3D printing and ink technology, applied in medical science, prosthesis, additive processing, etc., can solve the problems of uneven powder and poor degradability, uneven printing structure, increase process complexity, etc. Excellent biocompatibility, speed-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] 2. In the following examples, the acellular matrix powder used was prepared by the following method:

[0047] (1) Pretreatment: Cut the peripheral nerve tissue of mice into tissue blocks of 5mm×5mm×5mm, and wash them thoroughly with PBS solution;

[0048] (2) Decellularization: The peripheral nerve tissue was placed in a 3% Triton X 100 aqueous solution for 12 hours, rinsed three times in sterile distilled water, and then placed in a 4% sodium deoxycholate aqueous solution for 24 hours. Rinse 3 times in sterile distilled water. Repeat the above process twice;

[0049] (3) One-time freeze-drying: place the decellularized peripheral nerve tissue in a -80°C freeze-drying machine for freeze-drying;

[0050] (5) Degreasing: Use a mixed solvent of ethanol and dichloromethane to degrease the peripheral nerve tissue after one freeze-drying, wherein the volume ratio of ethanol and dichloromethane is 1:2. The bacteria are washed with distilled water for many times until the mi...

Embodiment 1

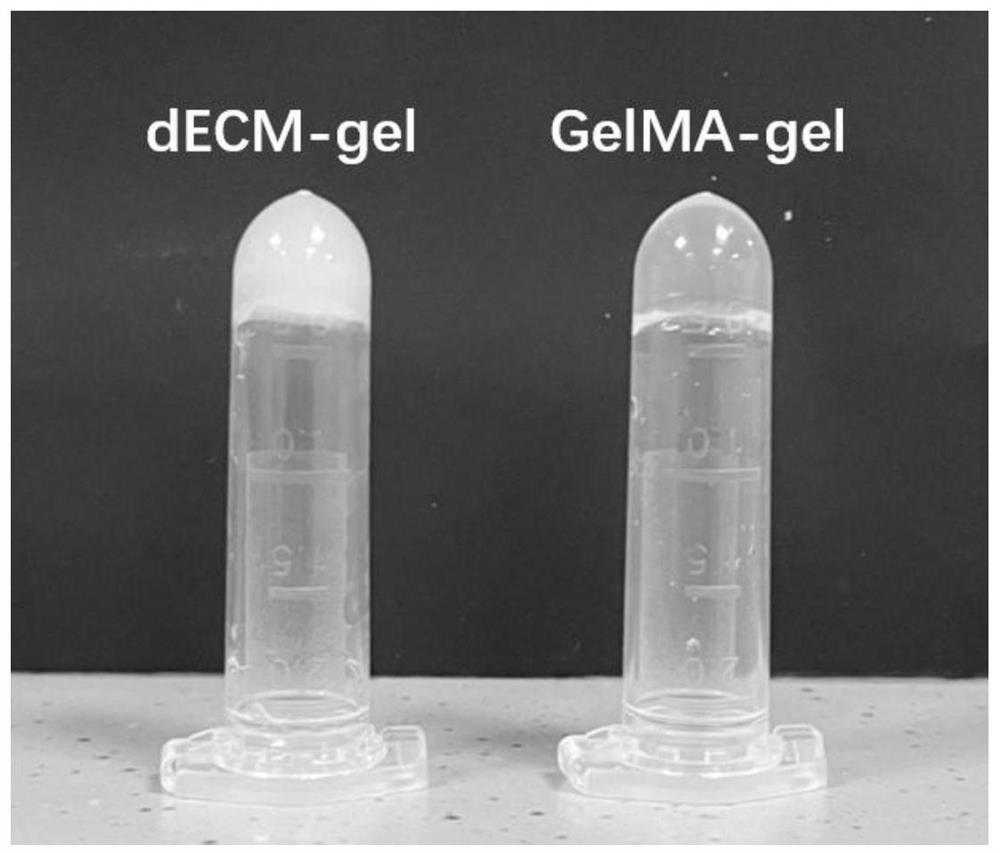

[0059] This example is used to illustrate the gelation properties of the peripheral nerve tissue acellular matrix of the present invention.

[0060] Weigh 10 mg of acellular matrix powder and digest it with 1 ml of pepsin solution to obtain a mass fraction of 1% acellular matrix solution. Adjust the pH of the acellular matrix solution to neutrality with NaOH solution to terminate the digestion, and add 10 × PBS solution to make The ionic strength of the acellular matrix solution was 1, and gelation at 37°C gave a mass fraction of 1% acellular matrix gel.

[0061] image 3 The physical image of the acellular matrix gel in this example, from image 3 It can be seen that the acellular matrix of peripheral nerve tissue can undergo sol-gel transition at 37°C and pH=7, from liquid state to solid state.

Embodiment 2

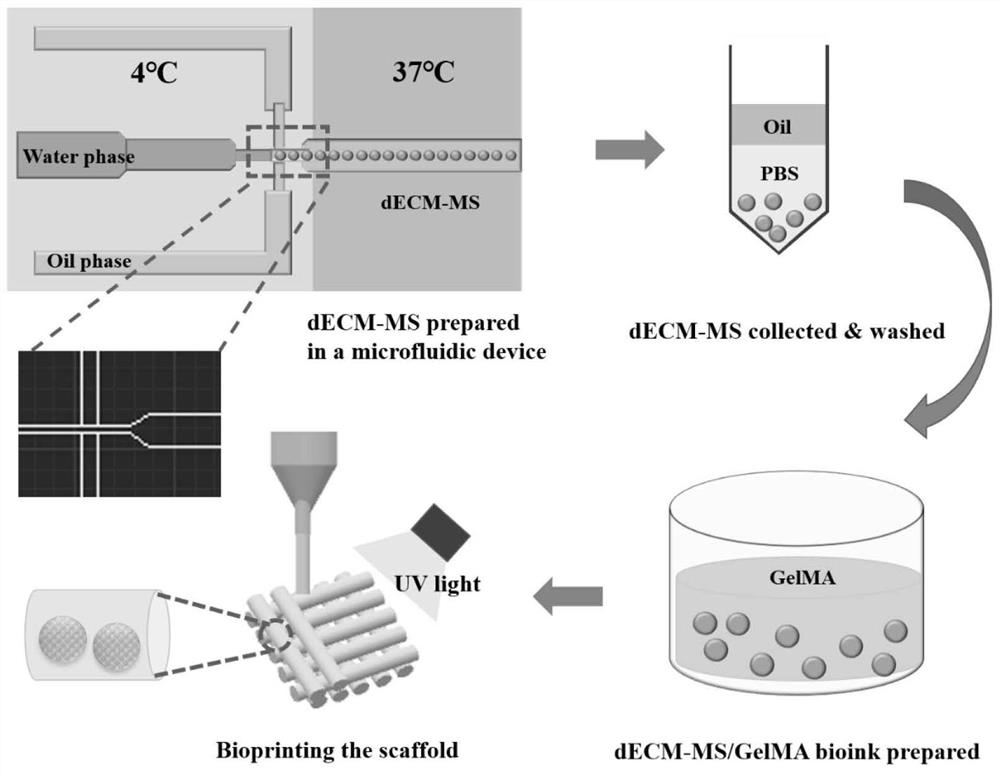

[0063] This example is used to illustrate the acellular matrix microspheres and the preparation method thereof, including the following steps:

[0064] (1) Preparation of microfluidic chip: After mixing the polydimethylsiloxane and the cross-linking agent in a mass ratio of 10:1, pour it on the master, where the cross-linking agent is sylgard 184 from Dow Corning, and then pour it on the master. Cured at 70℃ for 4h;

[0065] After curing, the polydimethylsiloxane mold is peeled off from the master, and then the channel inlet and channel outlet are punched out on the mold with a punch;

[0066] After punching, the polydimethylsiloxane mold is subjected to oxygen plasma treatment, adhered to the polydimethylsiloxane film, and finally cured at 70°C for 4 hours to obtain a microchannel chip;

[0067] (2) Preparation of the aqueous phase: The acellular matrix powder was added to the pepsin solution for digestion to obtain an acellular matrix solution with a mass fraction of 1%. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com